Metal separator for fuel cell, and fuel cell stack provided with same

A technology for metal separation and fuel cells, which is applied in fuel cell grouping, fuel cell parts, fuel cells, etc., can solve the problems that compression deformation and resistance increase cannot be completely eliminated, and achieves easy lamination, reduced flow resistance, The effect of lowering the manufacturing unit price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the metal separator for a fuel cell according to the present invention and a fuel cell stack including the metal separator will be described in detail.

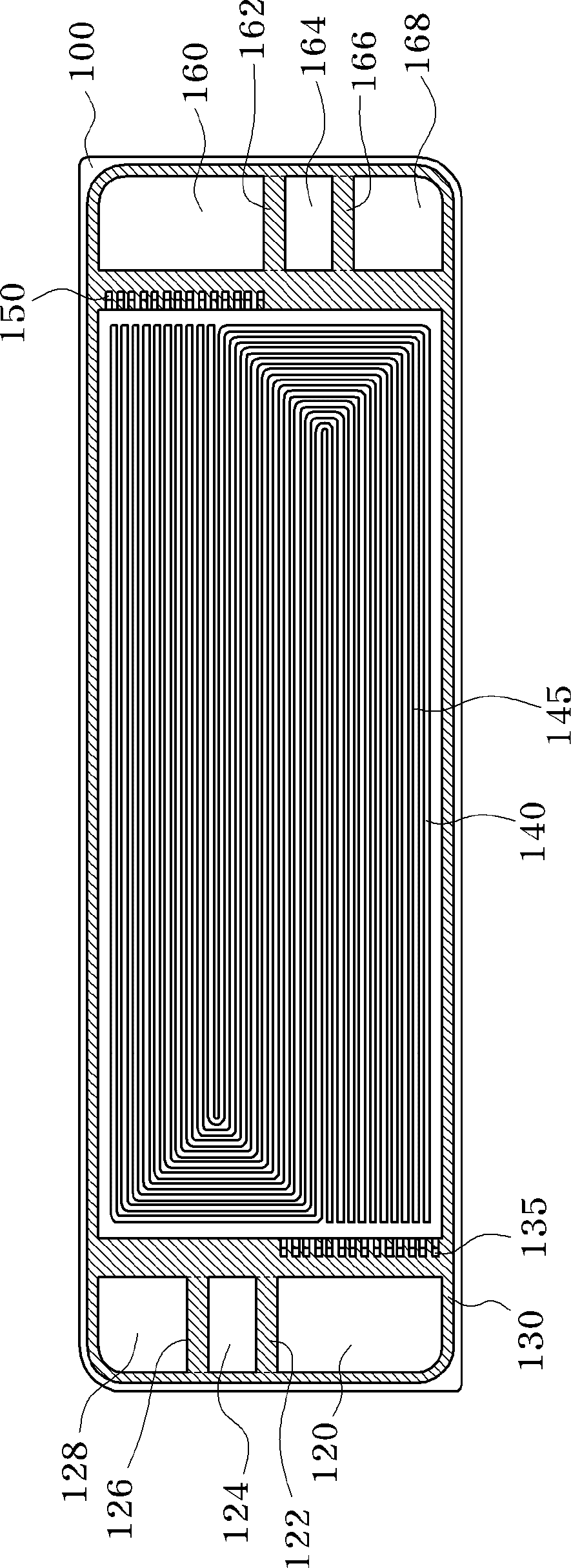

[0036] figure 1 It is a plan view showing the metal separator for fuel cells of the present invention.

[0037] refer to figure 1 , based on the metal body part 100, there are first reactant gas inflow manifold 120, cooling water inflow manifold 124, second reactant gas inflow manifold 128, first reactant gas discharge manifold 160, cooling water discharge The manifold 164 and the second reactant gas discharge manifold 168 have a reactant gas passage 140 and a cooling water passage 145 at the center of the metal body 100 .

[0038]Wherein, the reaction gas channel 140 is formed to protrude from the first surface of the metal body part to the second surface, and the cooling water channel 145 refers to the area between the protruding parts of the reaction gas channel 140 . Also, the central part of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com