Production method for improving flavor of chili sauce

A production method and technology of chili sauce, applied in application, food preparation, food science, etc., to achieve the effect of enriching varieties, alleviating irritation, and ensuring hygienic indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

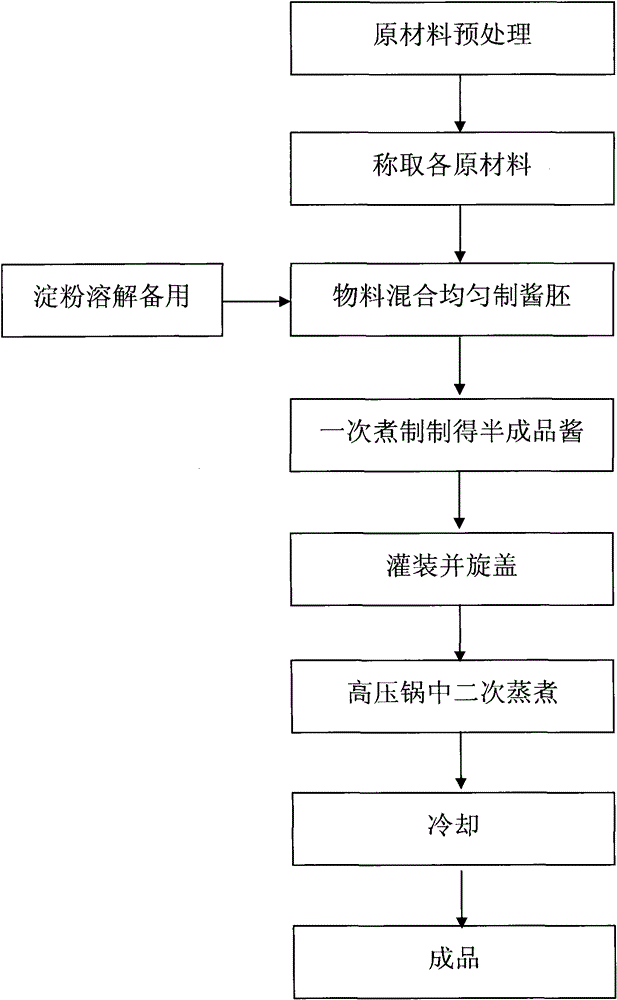

Image

Examples

Embodiment 1

[0021] 1) Pretreatment of raw materials: first remove the stems of peppers and wash them, peel and wash the garlic, and then chop the peppers and garlic;

[0022] 2) Weighing according to the formula: weigh 5kg of pepper, 0.8kg of garlic, 0.8kg of white sugar, 0.8kg of edible salt, 0.3kg of vinegar, 0.3kg of starch, and 3.5kg of water;

[0023] 3) The starch is fully dissolved with 1.5kg of water for later use;

[0024] 4) Sauce embryo making: Stir and mix the materials evenly;

[0025] 5) Making semi-finished sauce: heat the sauce embryo to boiling, keep boiling for 3 minutes, turn off the steam, and make semi-finished sauce;

[0026] 6) Bottle the semi-finished sauce and screw the cap;

[0027] 7) bottled and capped chilli sauce is put into autoclave;

[0028] 8) Heat to 105-110°C in an autoclave for 10-15 minutes, then cool to 50°C and take out of the pot.

Embodiment 2

[0030] The difference between Example 2 and Example 1 is that 0.05kg of minced ginger is added in step 2), heated to 110-125°C in a pressure cooker in step 8) and kept for 5-10 minutes, then cooled to 50°C, and taken out of the pot.

[0031] The chili sauce produced in Example 1 and Example 2 has an attractive color, a spicy but mellow taste, and a more perfect combination of the aroma of chili and garlic, which has a special taste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com