Photosensitive color-changing fabric machining process

A processing technology and photochromic technology, applied in the field of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

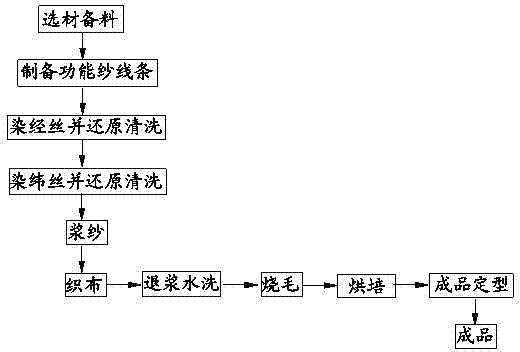

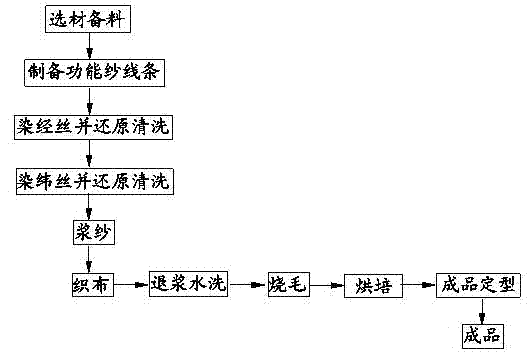

Image

Examples

Embodiment 1

[0025] The specific implementation steps are as follows:

[0026] a) Material selection and preparation, the proportion of each component of the fabric is: nano-bamboo carbon fiber 15%, spandex fiber 5%, natural cotton fiber 60%, color-changing photosensitive fiber 20%;

[0027] b) Preparation of functional yarns. The fabric is woven with warp and weft. The warp is made of nano-bamboo carbon fiber and natural cotton fiber and then processed into low-twist composite yarn through drawing, roving, spun yarn and winding processes. , the weft uses spandex fiber and color-changing photosensitive fiber to make spandex color-changing fiber through melt spinning, and then makes strips through cleaning and carding processes;

[0028] The color-changing photosensitive fiber is a photosensitive color-changing fiber material. The photosensitive color-changing fiber material is obtained by impregnating polyester fiber in a solution with a photosensitive color-changing compound. The process ...

Embodiment 2

[0043] The specific implementation steps are as follows:

[0044] a) Material selection and preparation, the proportion of each component of the fabric is: nano-bamboo carbon fiber 18%, spandex fiber 7%, natural cotton fiber 50%, color-changing photosensitive fiber 25%;

[0045] b) Preparation of functional yarns. The fabric is woven with warp and weft. The warp is made of nano-bamboo carbon fiber and natural cotton fiber and then processed into low-twist composite yarn through drawing, roving, spun yarn and winding processes. , the weft uses spandex fiber and color-changing photosensitive fiber to make spandex color-changing fiber through melt spinning, and then makes strips through cleaning and carding processes;

[0046] The color-changing photosensitive fiber is a photosensitive color-changing fiber material. The photosensitive color-changing fiber material is obtained by impregnating polyester fiber in a solution with a photosensitive color-changing compound. The process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com