Wicking and quick-drying knitted fabric and production method and application thereof

A production method and technology of knitted fabrics, applied in the field of knitted fabrics, can solve problems such as increasing costs and increasing technological processes, and achieve the effects of increased speed, sweat-conducting, cool and comfortable, and simple and easy production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

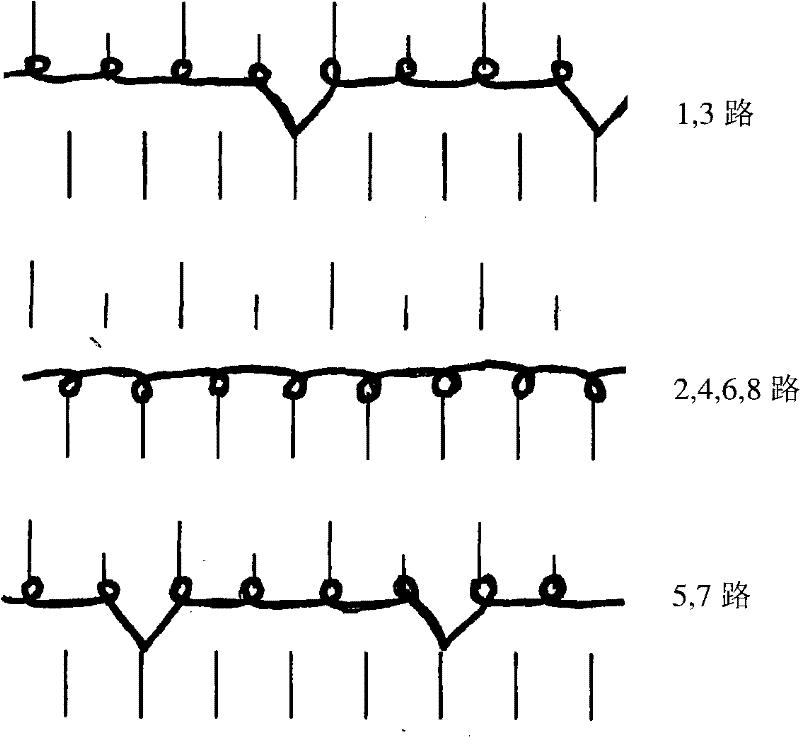

[0021] Using 44dtex-34f polyamide fully drawn yarn and 84dtex-72f polyester false twisted yarn (that is, the polyamide fiber monofilament fineness is about 1.11 times that of polyester fiber monofilament fineness), in 28G double-sided Weaving is carried out on the knitting machine, and the inner layer is a mesh structure with the cooperation of tucks, and the surface layer is a plain cloth structure. The design diagram is as follows figure 1 shown. After refining and degreasing, setting in the middle, dyeing, polyester fiber is finished with water-absorbing agent, and the weight is about 140g / m 2 of knitted fabrics.

[0022] The surface layer of the knitted fabric is mainly polyester fiber, and the inner layer is mainly polyamide fiber, which has good sweat-conducting ability, and the water absorption height of the surface layer is measured to be 1.82 times that of the inner layer.

Embodiment 2

[0024] Using 56dtex-18f polyamide fully drawn yarn and 84dtex-72f polyester false twisted yarn (that is, the monofilament fineness of polyamide fiber is about 2.66 times that of polyester fiber monofilament), in 28G double-sided Weaving is carried out on the knitting machine, and the inner layer is a mesh structure with the cooperation of tucks, and the surface layer is a plain cloth structure. The design diagram is as follows figure 1 shown. After refining and removing oil, setting in the middle, dyeing, polyester fiber is finished with water-absorbing agent, and the weight is about 150g / m 2 of knitted fabrics.

[0025] The surface layer of the knitted fabric is mainly polyester fiber, and the inner layer is mainly polyamide fiber, which has good sweat-conducting ability, and the water absorption height of the surface layer is measured to be 2.7 times that of the inner layer.

Embodiment 3

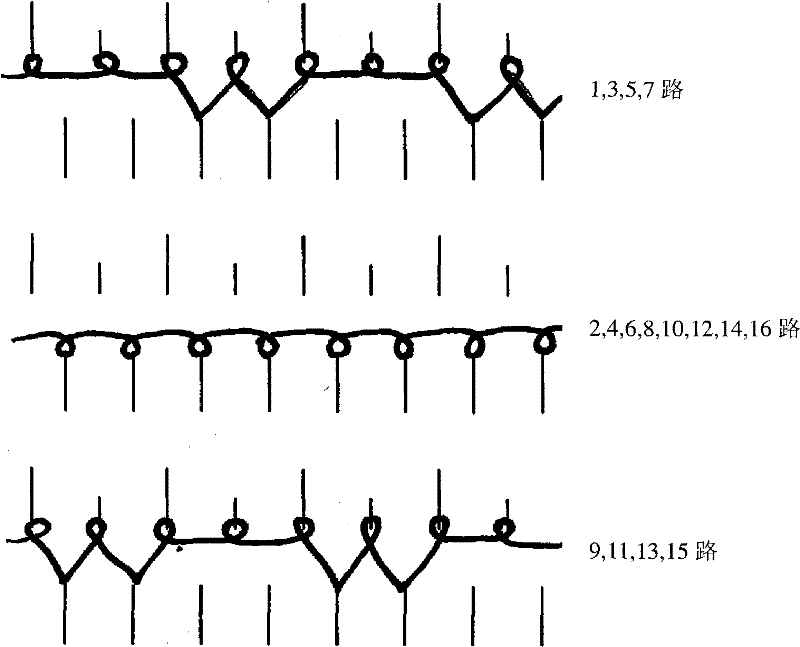

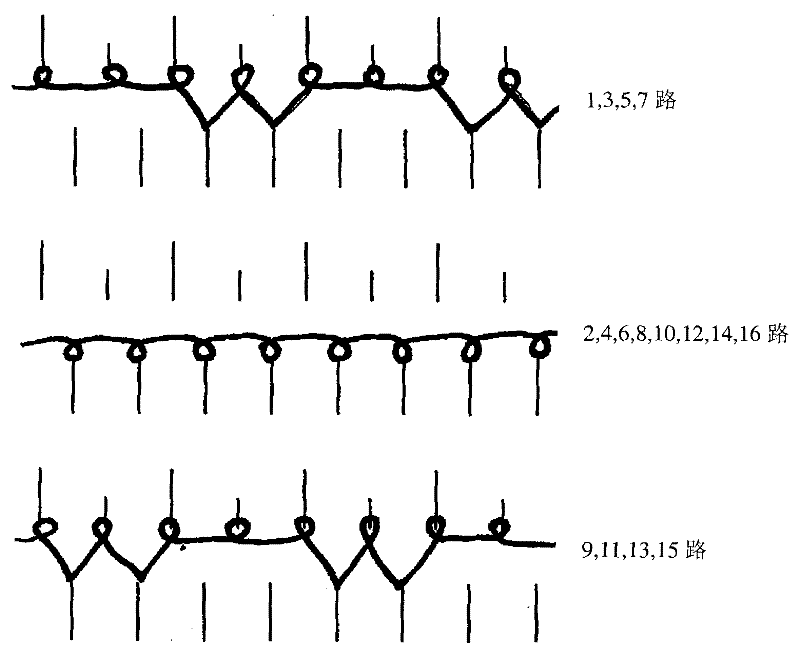

[0027] Using 56dtex-17f polyamide false twist yarn and 84dtex-72f polyester false twist yarn (that is, the monofilament fineness of polyamide fiber is about 2.82 times that of polyester fiber monofilament), in 28G double-sided knitting Weaving is carried out on the machine, and the inner layer is a honeycomb structure with the cooperation of tucks, and the surface layer is a flat cloth structure. The design diagram is as follows: figure 2 shown. After refining to remove oil, intermediate setting, dyeing, polyester fiber is finished with water-absorbing agent, and the weight is about 163g / m 2 of knitted fabrics.

[0028] The surface layer of the knitted fabric is mainly polyester fiber, and the inner layer is mainly polyamide fiber, which has good sweat-conducting ability, and the water absorption height of the surface layer is measured to be 2.8 times that of the inner layer.

[0029] Application of the knitted fabric prepared in Examples 1-3 on sportswear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com