Method for manufacturing alignment film for liquid crystal, method for manufacturing liquid crystal element, apparatus for manufacturing alignment film for liquid crystal, liquid crystal element

A manufacturing method and a technology of an alignment film, applied in nonlinear optics, instruments, optics, etc., can solve problems such as high material costs, high processing costs, and complex manufacturing processes, and achieve high anchoring strength, excellent controllability, and long-term stability sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

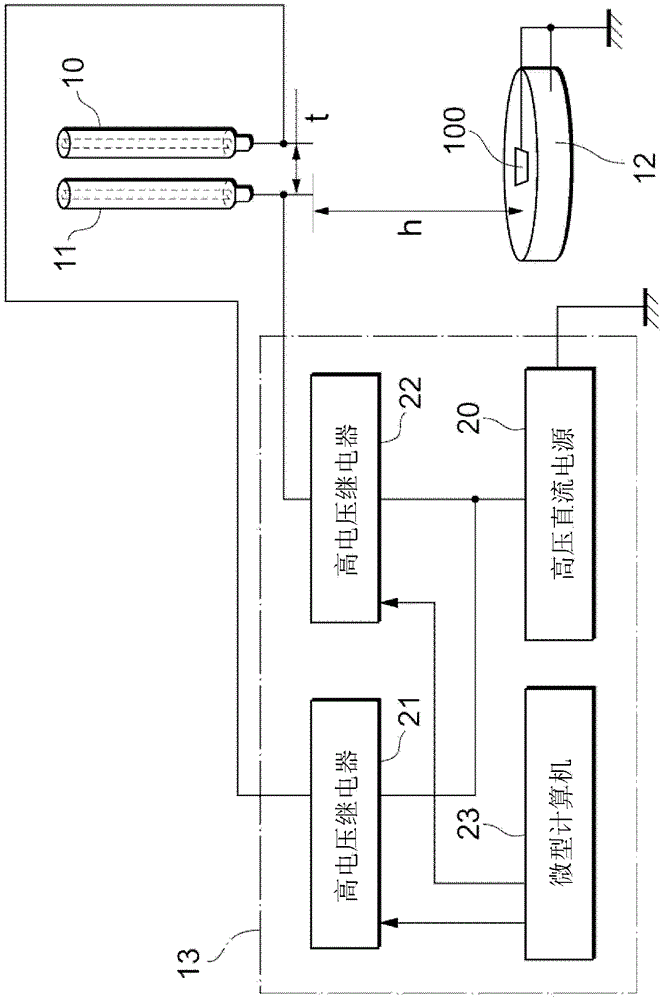

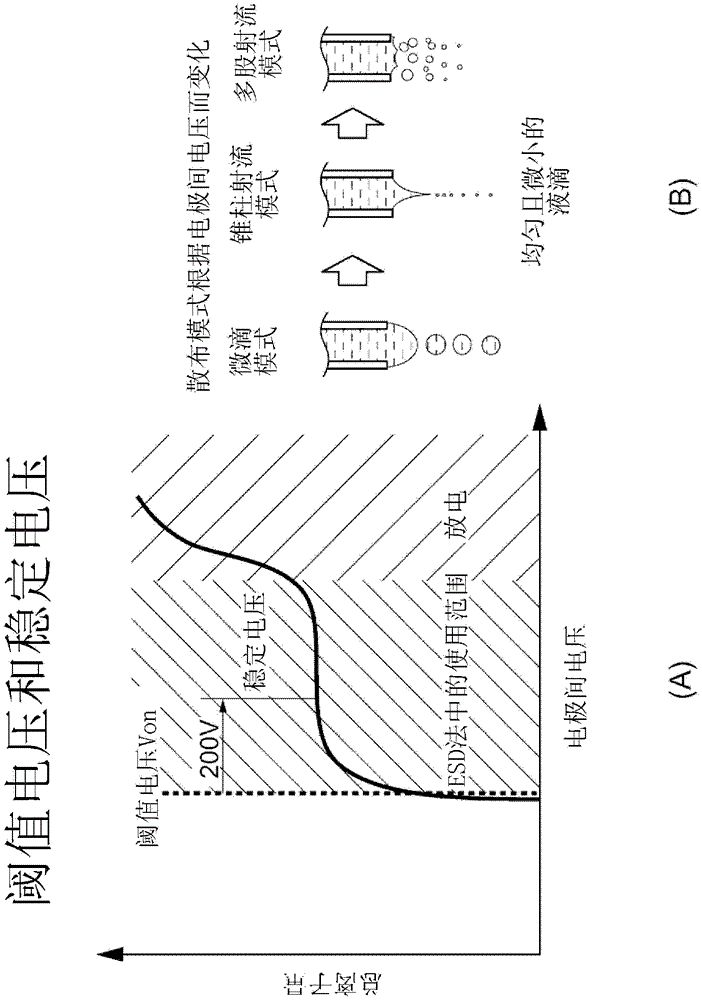

[0044] figure 1 It is a schematic diagram showing the structure of the manufacturing apparatus of the alignment film of 1st Embodiment. figure 1 The manufacturing apparatus of the alignment film shown has two spraying devices 10, 11, a substrate holder (substrate holder) (substrate fixing unit) 12, and a voltage applying device 13, and the two spraying devices 10, 11 have a cylindrical shape, etc. A syringe (barrel) for holding a material liquid of an alignment film (hereinafter referred to as "alignment film liquid") inside and a hollow microneedle provided at one end of these syringes, the substrate holder ( The substrate fixing unit) 12 is used to hold the substrate 100 , which is the object for forming an alignment film by these spraying devices 10 , 11 , and the voltage applying device 13 is used to apply voltage to each spraying device 10 , 11 . As shown in the figure, the injection device 10 and the injection device 11 are arranged adjacent to each other. The voltage ...

Embodiment 1

[0065] A pair of glass substrates (thickness of ITO: 1500 angstroms, glass plate thickness: 0.7 mm, glass material: non-alkali glass) on which transparent electrodes such as ITO were formed were prepared. These substrates were cleaned, and ITO was patterned using a normal photolithography process. Here, wet etching (ferric chloride) was used as the ITO etching method.

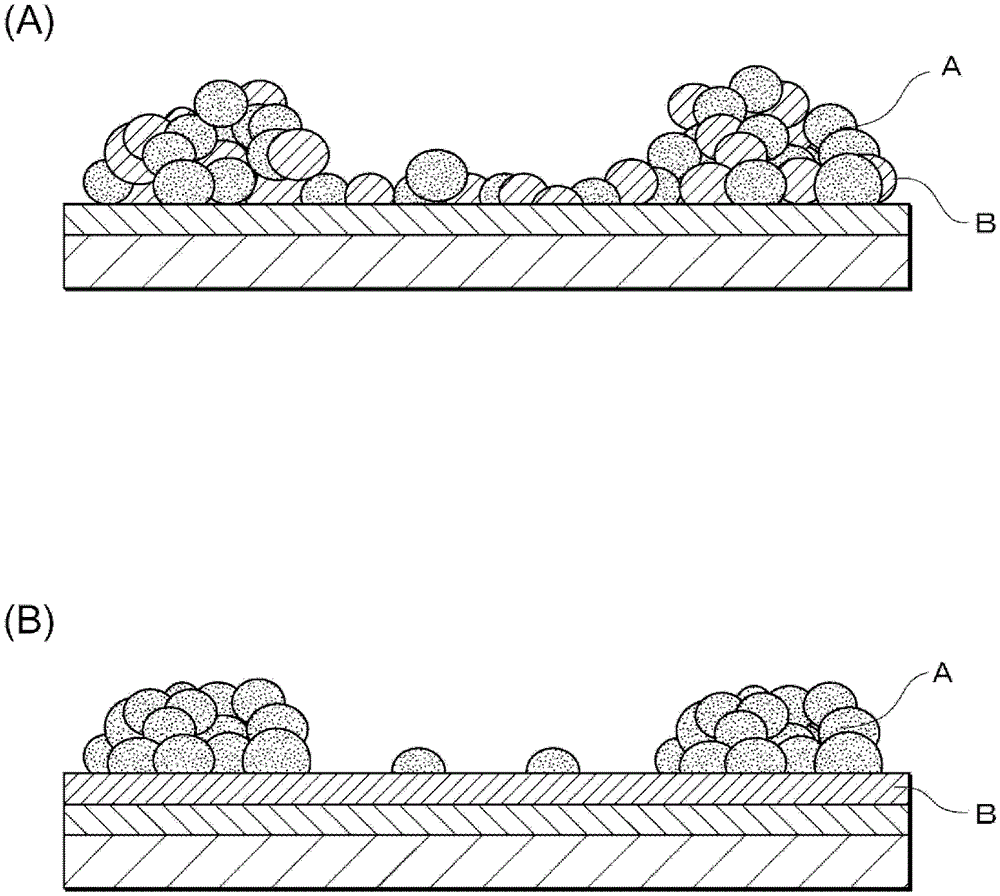

[0066] Next, on the glass substrate on which the ITO was patterned, the alignment film liquid (orientation material) was sprayed by the electrospray deposition method. A mixed solution of a horizontal alignment material (manufactured by PI-A Nissan Chemical Industry Co., Ltd.: 4 wt %) and a solvent (methylene chloride) is filled in the syringe of one of the jetting devices 10, and a vertical alignment material is filled in the syringe of the other jetting device 11. A mixed solution of a material (Nissan Chemical Industry Co., Ltd. SE-1211: 4 wt %) and a solvent (DCM) was simultaneously sprayed from each of th...

Embodiment 2

[0072] As Example 2, a method of temporally and alternately dispersing different materials was studied. The same steps as in Example 1 were used except for the formation step of the alignment film. In the syringe of one of the injection devices 10, fill the mixed solution of the horizontal alignment material (PI-A identical to the above-mentioned embodiment 1: 4wt%) and the solvent (methylene chloride and γ-butyrolactone), and in another injection device Fill the syringe of 11 with a mixed solution of vertical alignment material (SE-1211 the same as the above-mentioned Example 1: 4wt%) and solvent (dichloromethane and γ-butyrolactone), and the spraying devices 10 and 11 time-divisionally Each mixed solution was dispersed. Specifically, the microcomputer 23 selectively controls the high voltage relays 21 and 22 to be on at a predetermined time ratio, and the high voltage DC power supply 20 applies voltage to the needles of the injection devices 10 and 11 . Each cycle (spreadi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com