Integration measuring method of wavefront distortion and optical axis vibration of space camera

A wavefront distortion and space camera technology, applied in optics, instruments, photography, etc., can solve the problems of high measurement speed and unsuitability for measurement, and achieve the effects of improving imaging quality, convenient calibration, and good consistency of measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described;

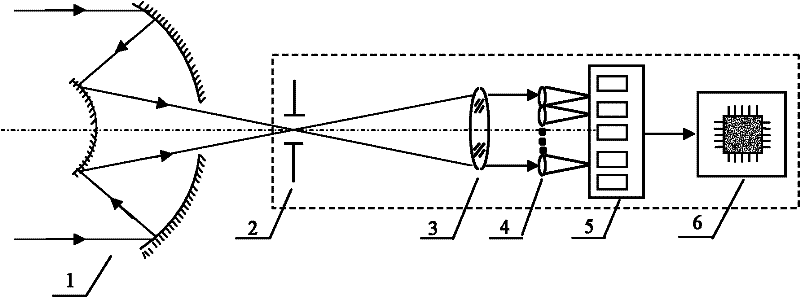

[0051] The present invention is achieved in this way: through the improvement and optimal design of the system composition and use mode of the relevant Hartmann-Shack wavefront sensing method, an integrated measurement device for wavefront distortion and optical axis jitter is obtained, which can be used for both High-resolution wavefront distortion measurement can also be used for high-frequency optical axis jitter measurement, which can save a detector and realize the integrated measurement of space camera wavefront distortion and optical axis jitter error.

[0052] The improvement and optimal design of the integrated measurement method referred to in the present invention in terms of the composition of the measurement system to the relevant Hartmann-Shack wavefront sensing method include:

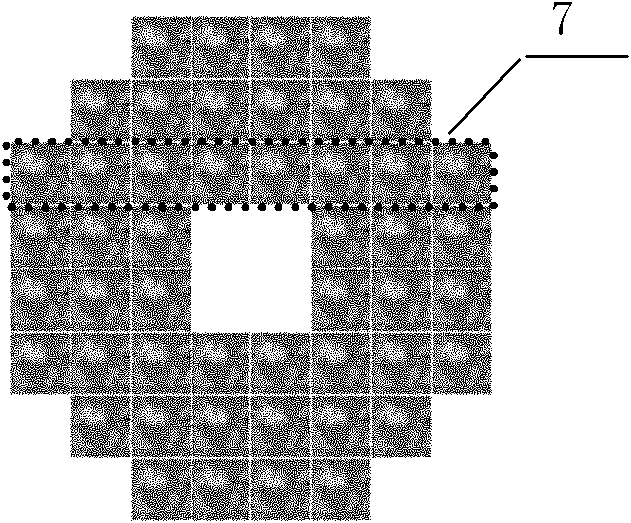

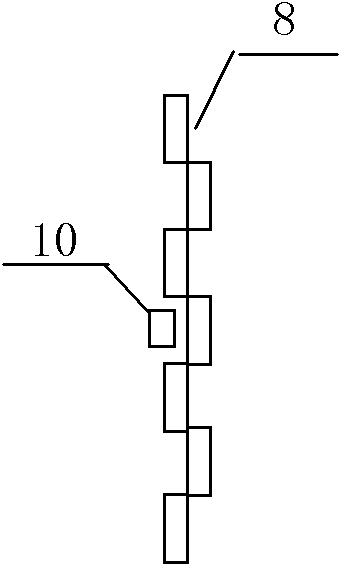

[0053] 1. The image detector 5 in the integrated measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com