A foundry binder comprising one or more cycloalkanes as a solvent

A binder and cycloalkane technology, which is applied in the field of foundry binders, can solve the problems of non-polar solubility, limited dosage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

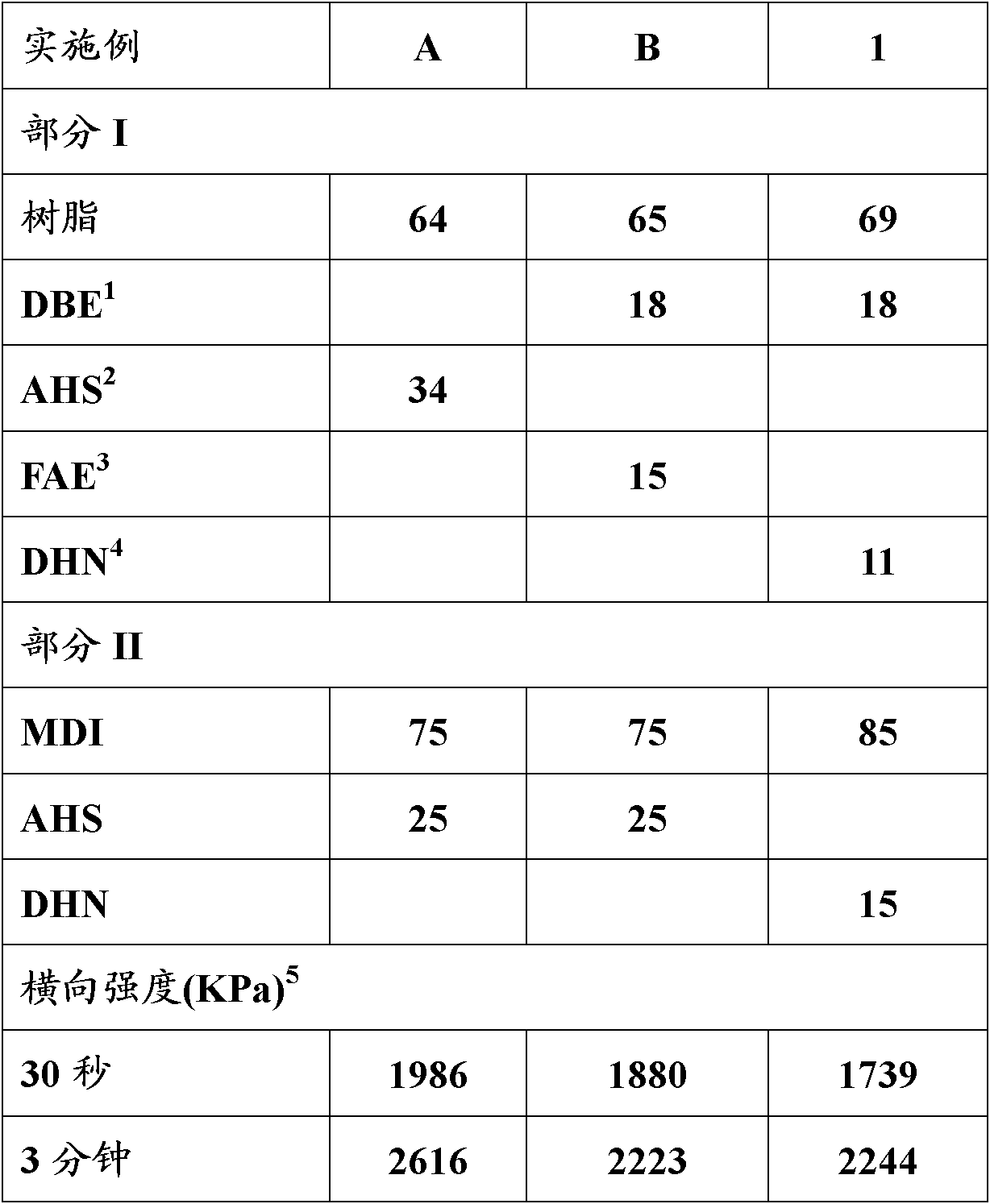

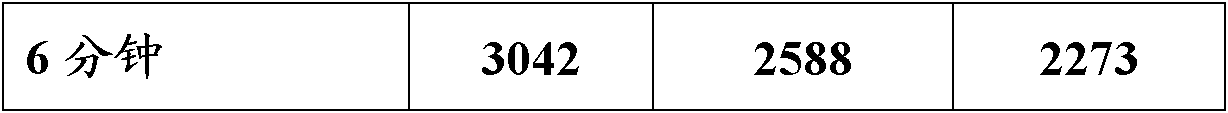

Embodiment A、B、1 and 2

[0071] Test casting cores were prepared by the cold box method: Congleton HST 50 quartz sand (from WBB minerals, Sibelco UK Ltd.) was first mixed with the binder formulation described in Table 1 in a Kenwood Chef mixer for one minute. The resole phenolic resin (RESIN) used in Part I of the binder was a polybenzyl ether type phenolic resin prepared by methods well known in the art using zinc acetate dihydrate as a catalyst. The polyisocyanate used in part II of the binder was poly(methylene diphenylisocyanate) with a functionality of 2.7. Equal amounts of Part I and Part II were used and the total amount of binder used was 1.2% by weight of the sand weight.

[0072] The resulting foundry mixture was pressed into the cavity by blowing the foundry sand mixture into a metal form (here solidified by the cold box method as described in US Patent 3,409,579) to obtain a test core measuring 120mm x 22.4mm x 6mm . Samples were formed by contacting the test cores with a mixture of trie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com