Embossed carrier tape and method for manufacturing the same

An embossing and carrier tape technology, applied in transportation and packaging, electrical components, packaging, etc., can solve the problems of difficulty in obtaining transparency, shape accuracy and flexural strength of micro-embossed parts, and achieve good transparency and shape accuracy. and excellent flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0057] In Embodiment 1, a sheet obtained by biaxially stretching a styrene-based resin composition is used.

[0058] Here, the styrenic resin refers to a homopolymer or a copolymer of a styrenic monomer, including, for example, general-type polystyrene resin (hereinafter referred to as "GPPS resin"), impact-resistant polystyrene resin (hereinafter Referred to as "HIPS resin"), various resins such as styrene-conjugated diene block copolymers, styrene-(meth)acrylate copolymers, and mixtures of one or more of them.

[0059] A representative example of the blend of styrenic resin compositions constituting the sheet is a mixture of GPPS resin and HIPS resin, or a mixture further containing a styrene-conjugated diene block copolymer in the mixture.

[0060] The GPPS resin (A) is a resin basically composed of styrene units, and is not particularly limited. In order to maintain the strength and transparency of the embossed carrier tape, its weight-average molecular weight is based on ...

Embodiment approach 2

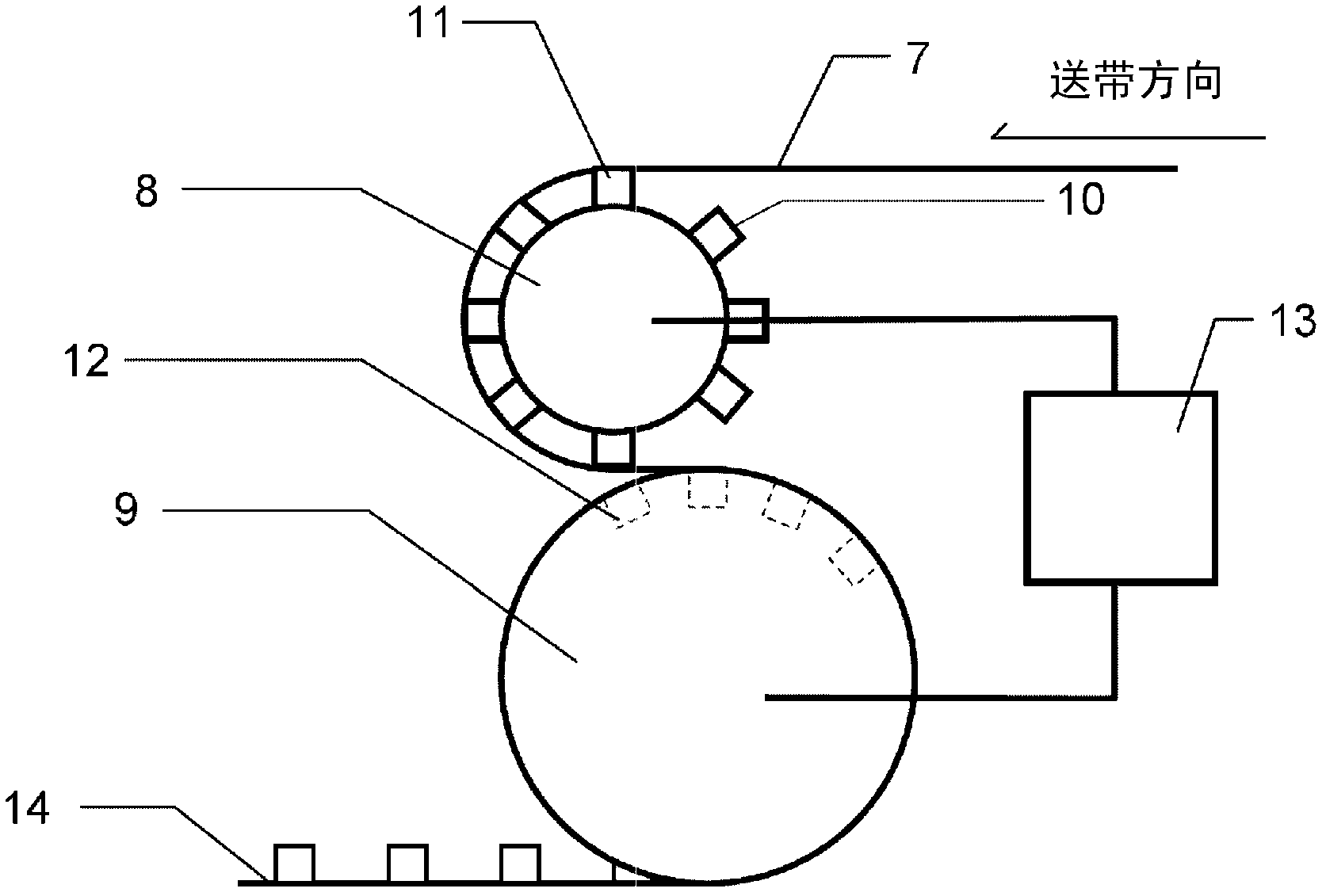

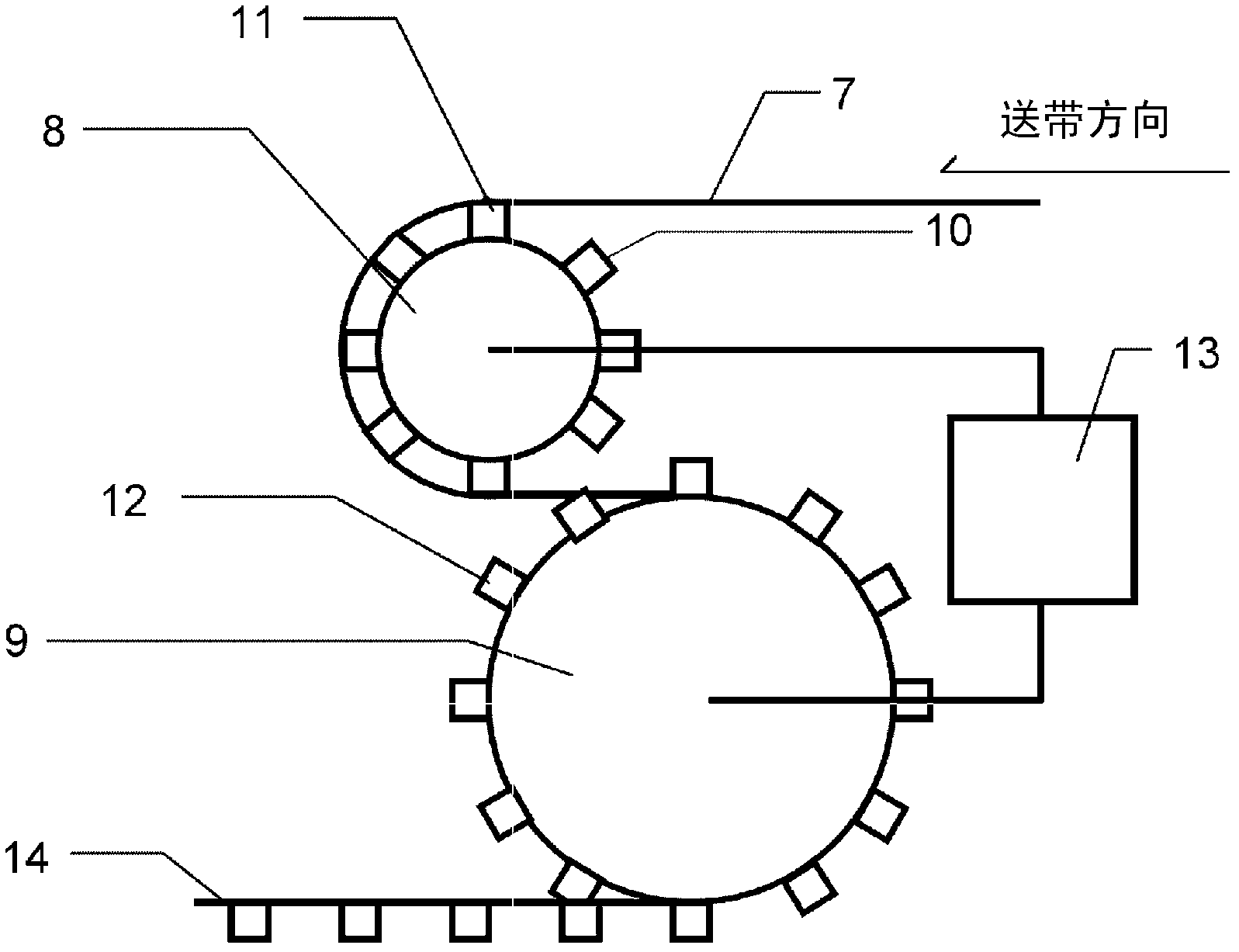

[0104] Refer below figure 2 as well as image 3 Embodiment 2 of the manufacturing method of the embossed carrier tape of this invention is demonstrated. It should be noted that Embodiment 2 is different from Embodiment 1 mainly in that the embossed portion is formed by rotating the vacuum forming die 9 using the cylindrical heater 8 .

[0105] In addition, in Embodiment 2, the description of the structure which overlaps with Embodiment 1 is abbreviate|omitted.

[0106] The method for producing an embossed carrier tape according to Embodiment 2 uses the same biaxially stretched sheet as in Embodiment 1, and includes: (a) a step of cutting the sheet into tapes; A step of continuously heating the region where the embossed portion is to be formed with a rotating cylindrical heater, and (c) a step of continuously forming the embossed portion in the heated region with a rotating cylindrical rotary vacuum forming mold.

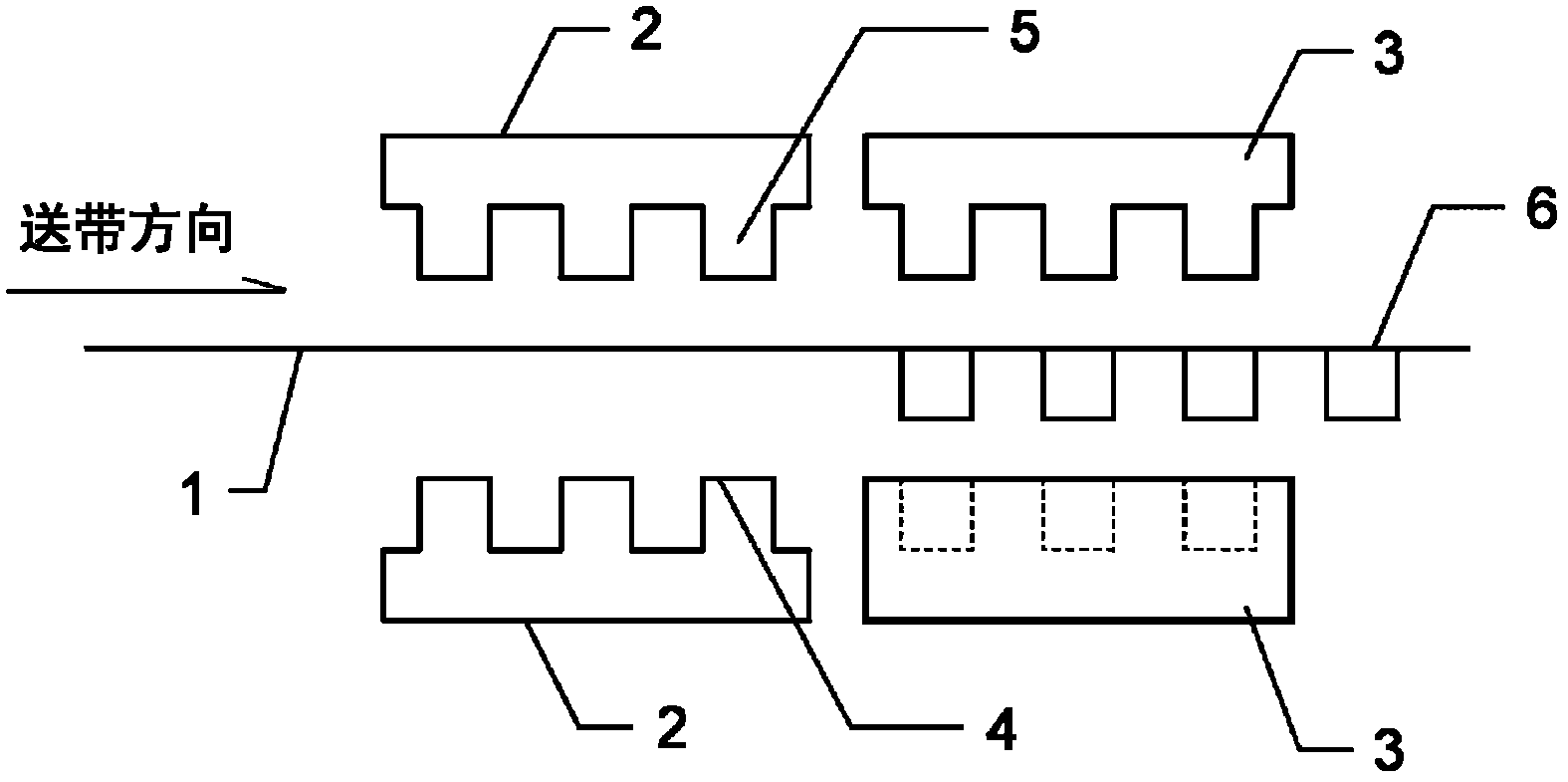

[0107] That is, if figure 2 or image 3 As shown, a tape...

Embodiment 1-10

[0153] In Examples 1-10, resin 1 was used as GPPS resin (A), and resin 2 was used as HIPS resin (B). In addition, select styrene / butadiene mass ratio and resin 3-5 that the molecular weight of styrene segment part is different as the resin containing styrene-butadiene block copolymer (C), according to the matching shown in table 1 Mix them together to make various resin compositions.

[0154]Next, each resin composition was melt-kneaded by an extruder and extruded from a T-die to obtain an unstretched sheet. Next, stretch the unstretched sheet 2.3 times in the longitudinal direction using a longitudinal stretching machine under heating at 90-135°C, and then stretch it in the transverse direction using a transverse stretching machine under heating at 90-135°C. 2.3 times to obtain the biaxially stretched sheets of Examples 1-10.

[0155] Next, the orientation relaxation stress, haze, tensile elastic modulus, sheet impact properties, and folding strength of each of the obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com