Fume Extraction Hood

A hood and air exhaust technology, which is applied in the direction of oil fume removal, combustion product treatment, household heating, etc., can solve the problem of inability to discharge cooking oil fumes, and achieve the effect of small energy loss and weakened airflow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

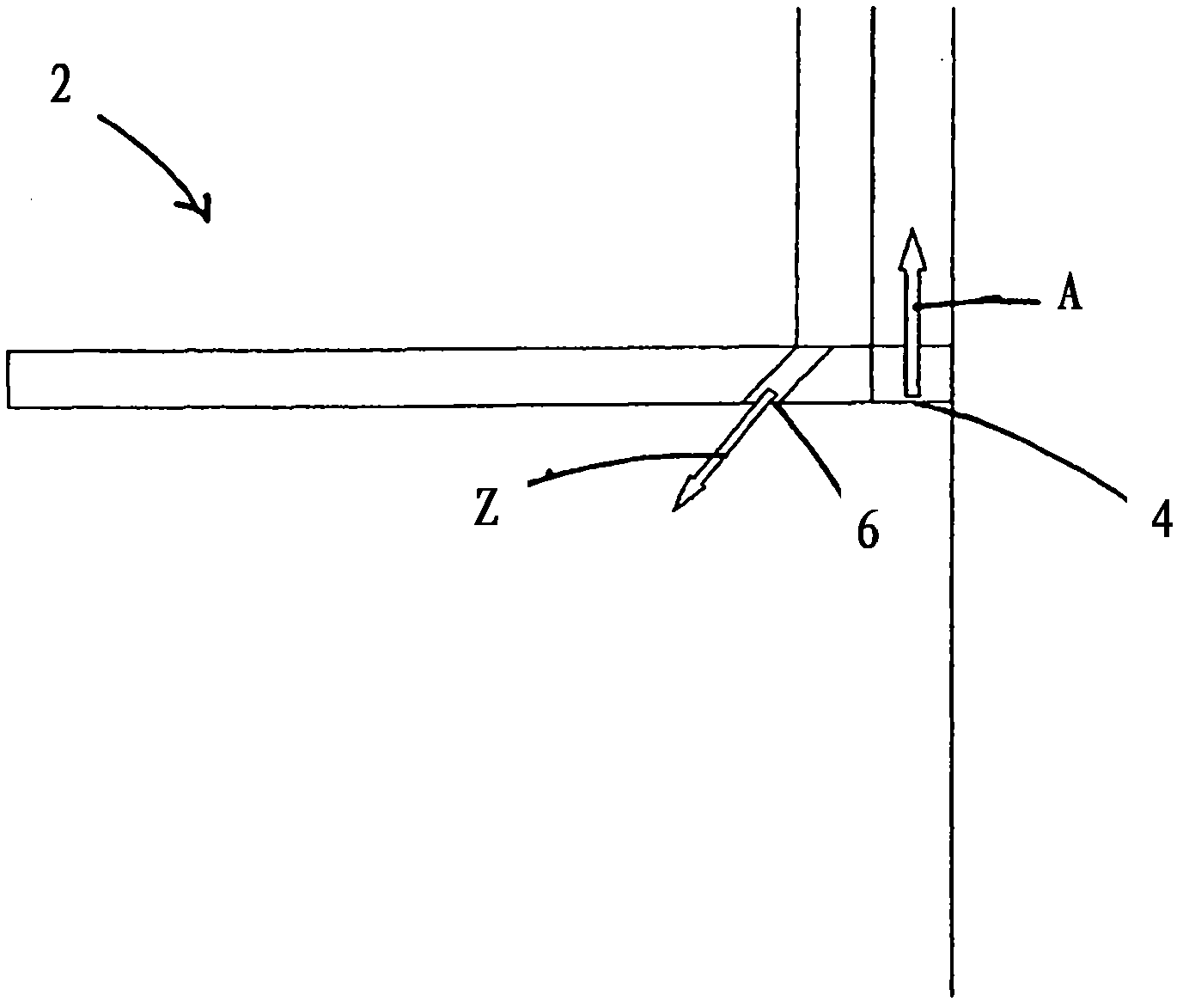

[0037] figure 1 The hood 2 fastened to the wall is shown in a schematic side view. The smoke extractor 2 has a suction outlet 4 and an air inlet 6 . The incoming air Z enters the galley space via the air inlet 6 , while the exhaust air A is sucked away from the galley space via the suction port 4 . In the schematic side view it can be seen that the inlet air Z and the outlet air A are oriented in opposite directions.

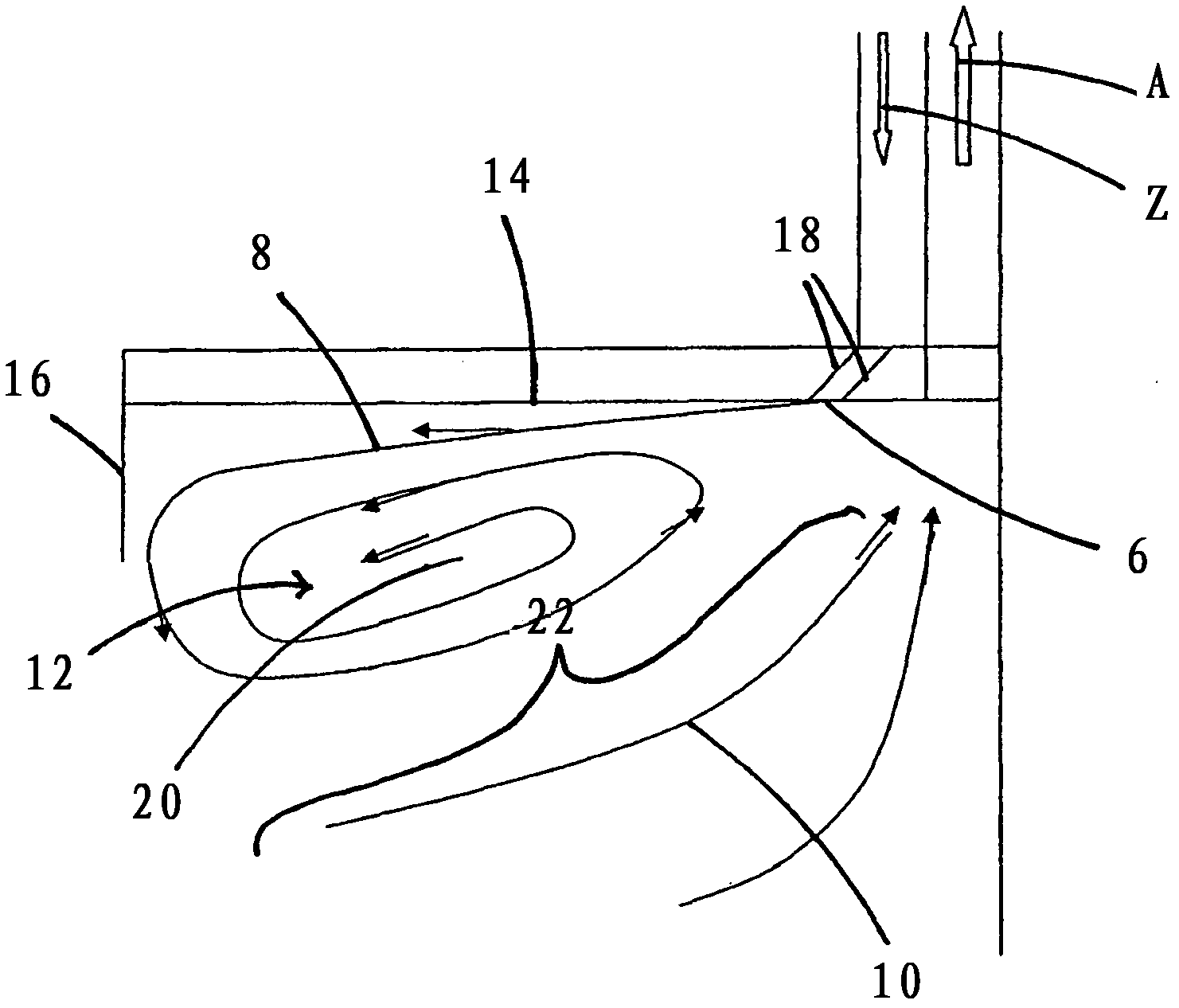

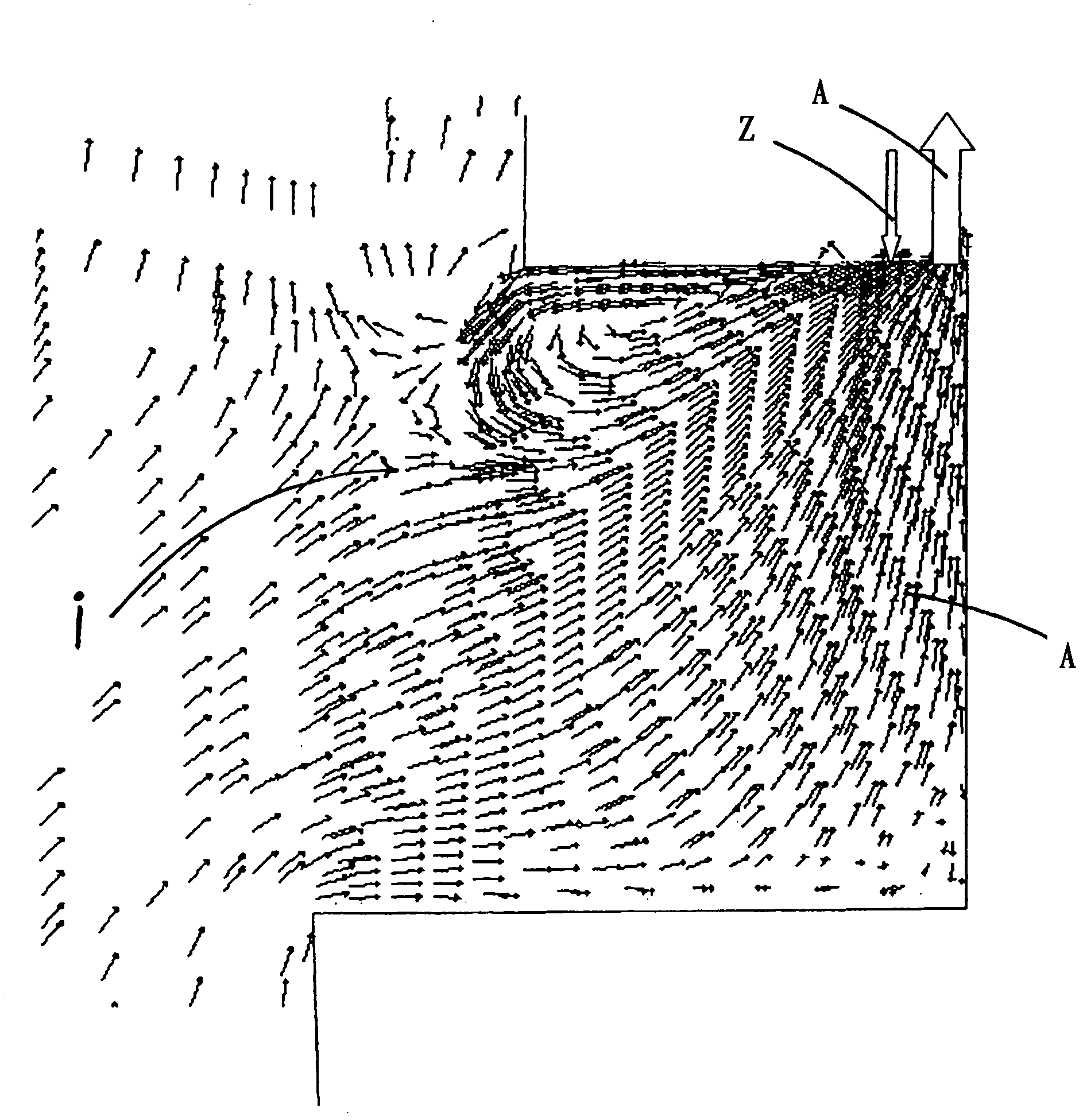

[0038] figure 2 The situation of the incoming air flow 8 and the outgoing air flow 10 is further shown in a schematic side view in FIG. from figure 2 It can be seen that the incoming air flow 8 exits the air inlet 6 and flows approximately in the direction of the outgoing air flow 10 . Starting from the air inlet, the incoming air flow 8 moves counter to the direction of flow of the outgoing air flow 10 and along the wall 14 present in the exemplary embodiment until the incoming air flow 8 reaches the region of the deflection surface 16 . Starting from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com