Coated abrasive tool and processing method thereof

A technology of coated abrasives and processing methods, which is applied in the direction of metal processing equipment, abrasives, grinding devices, etc., can solve the problems of unstable grinding performance, unsatisfactory wear resistance and durability effects, and achieve grinding ability Stable, good elasticity, good cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

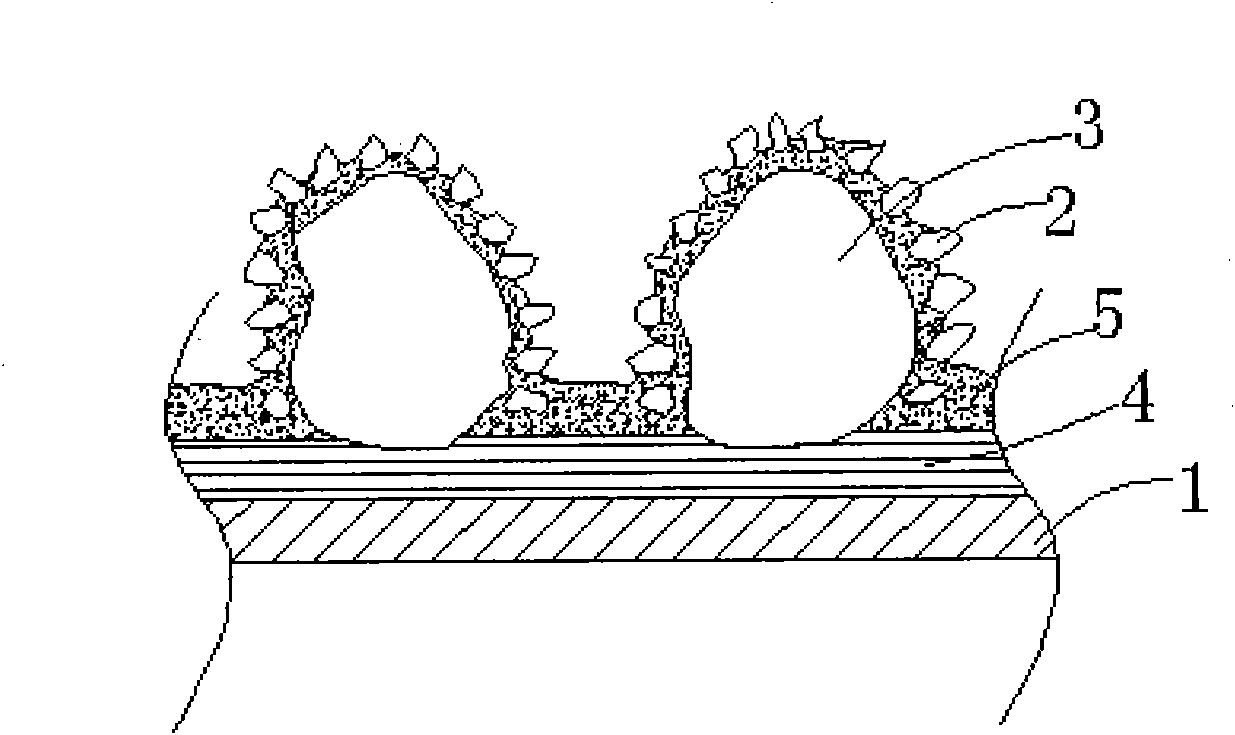

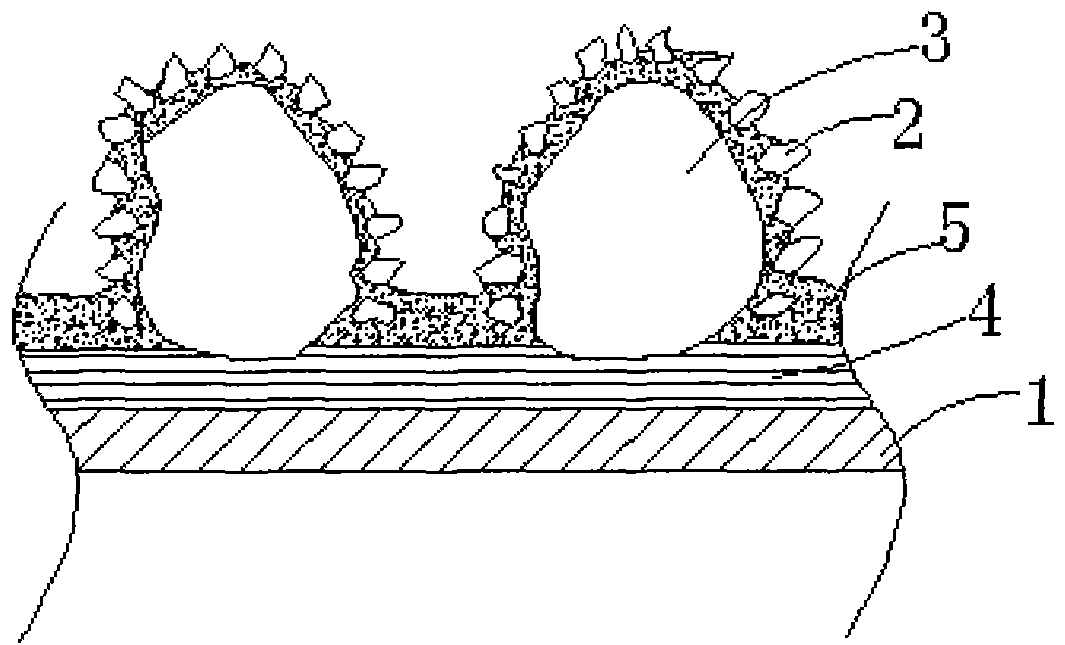

[0022] Embodiment: a kind of coated grinding tool, comprises substrate 1, binding agent and abrasive material 2, is characterized in that: also has some cork particles 3, and described several cork particles and abrasive are adhered to described substrate together by bonding agent superior.

[0023] The abrasive is distributed in the gaps between the cork particles and on the surface of the cork particles.

[0024] The cork particles are 5-10 mesh larger than the abrasive.

[0025] The adhesive includes a primer layer 4 and an overcoat layer 5, the thickness of the undercoat layer is 0.06-0.1 mm, and the thickness of the overcoat layer is 0.1-0.15 mm. Generally, the coating of the primer in the coated abrasive tool is about 0.03-0.05mm, and the coating of the compound glue is about 0.07-0.1mm. In the present invention, because the cork particles are relatively large, the thickness of the primer and the compound glue must be Increase by about 0.03-0.05mm.

[0026] The proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap