Method for processing fixed bed fishing coker gas oil

A coking wax oil, supplementary refining technology, applied in the petroleum industry, hydroprocessing process, only multi-stage series refining and cracking process treatment, etc., can solve the problem of water-washing emulsified denitrification components residues and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

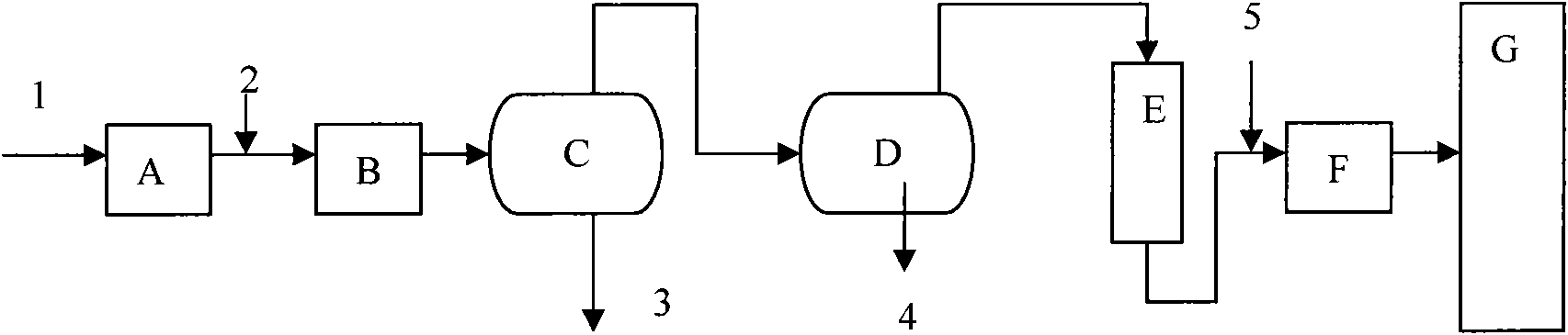

Method used

Image

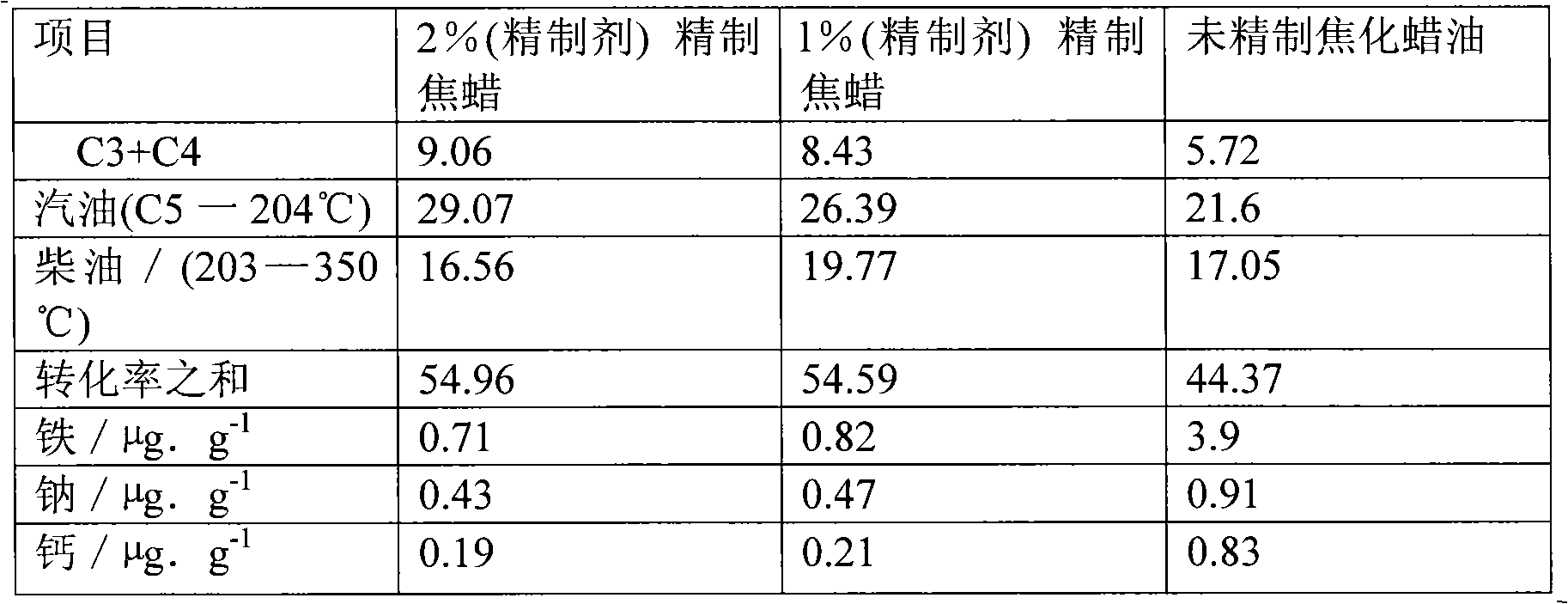

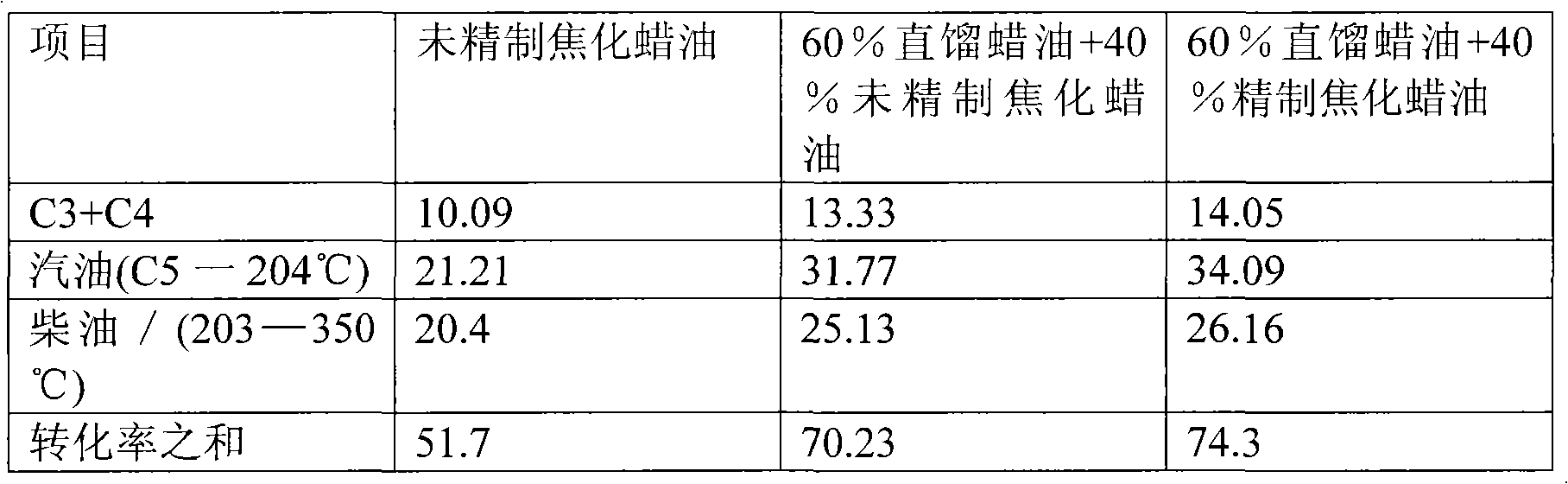

Examples

Embodiment 1

[0029] Use 10g of white clay as a filler to fill a column, pass the denitrified coker wax oil through a fixed bed at 0.5g / min, and obtain refined oil after adsorption and filtration. After analysis, the acid value is reduced from 1.08mgKOH / g to 0.054mgKOH / g g.

Embodiment 2

[0031] Use 10g of activated clay that absorbs inorganic acid as a filler to fill a column, pass the denitrified coker wax oil through a fixed bed at 0.5g / min, and obtain refined oil after adsorption and filtration. After analysis, the acid value is from 0.98mgKOH / g down to 0.051mgKOH / g.

Embodiment 3

[0033] Use 10g of activated carbon that absorbs inorganic salts as a filler to fill a column, pass the denitrified coker wax oil through a fixed bed at 0.5g / min, and obtain refined oil after adsorption and filtration. After analysis, the acid value is reduced by 0.95mgKOH / g to 0.49mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com