Fully-automatic gas-shielded welding robot with single gun, double wires and high speed

A welding robot and fully automatic technology, applied in welding equipment, electrode characteristics, arc welding equipment and other directions, can solve the problems of high labor intensity, long work cycle and slow welding speed of workers, and achieve automatic correction of welding position and welding time. Growth, high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific implementation plan

[0045] The present invention will be further described below in conjunction with the drawings:

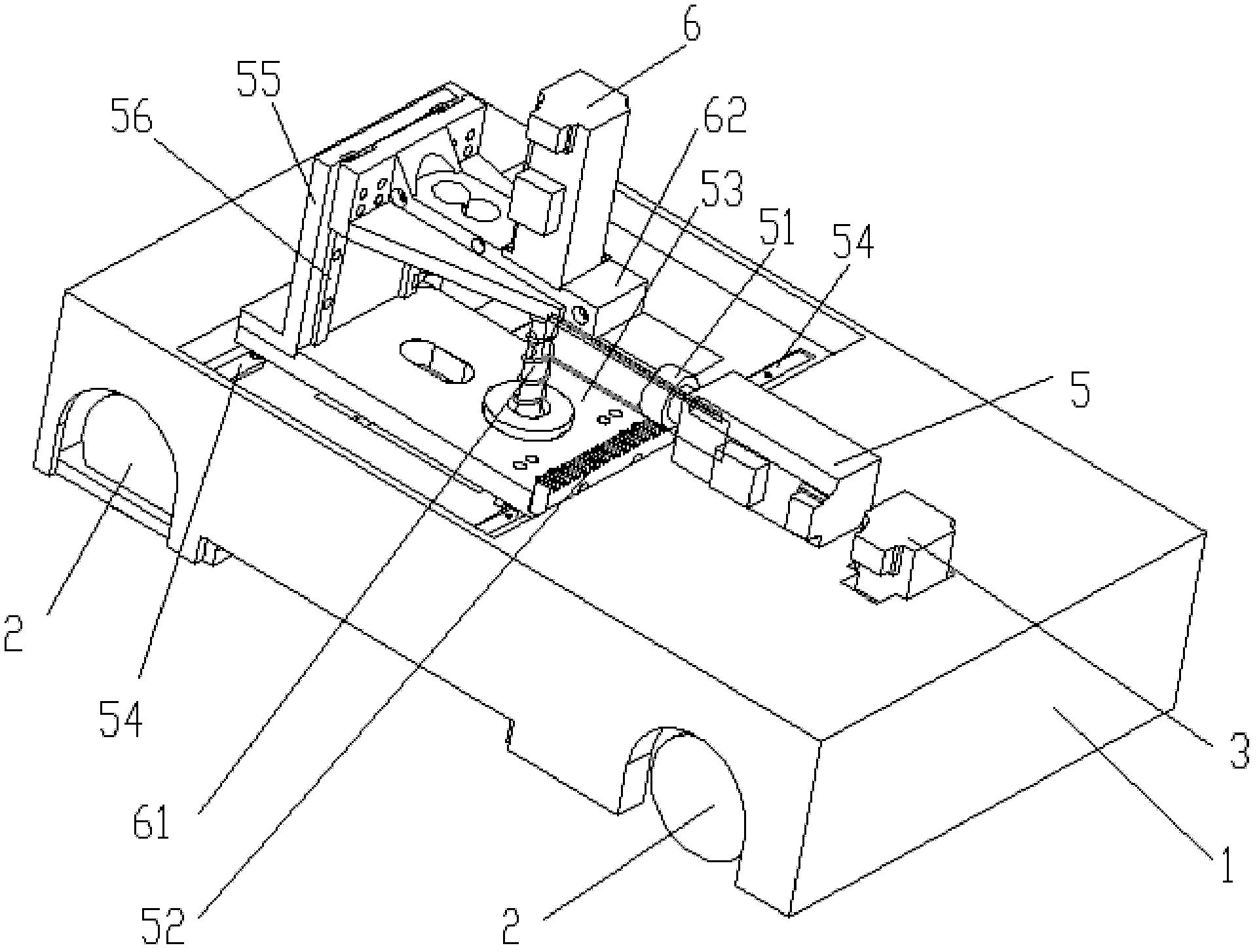

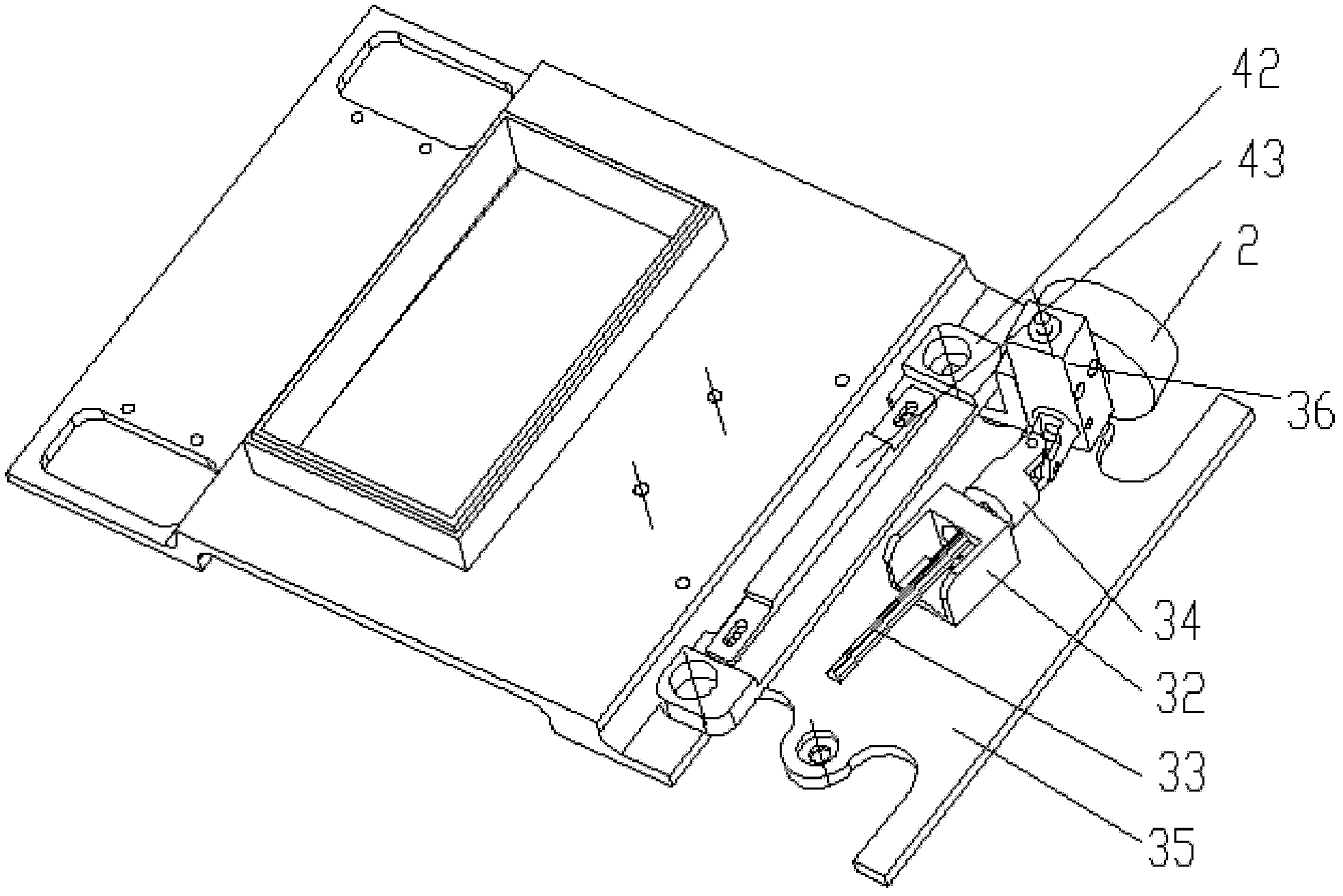

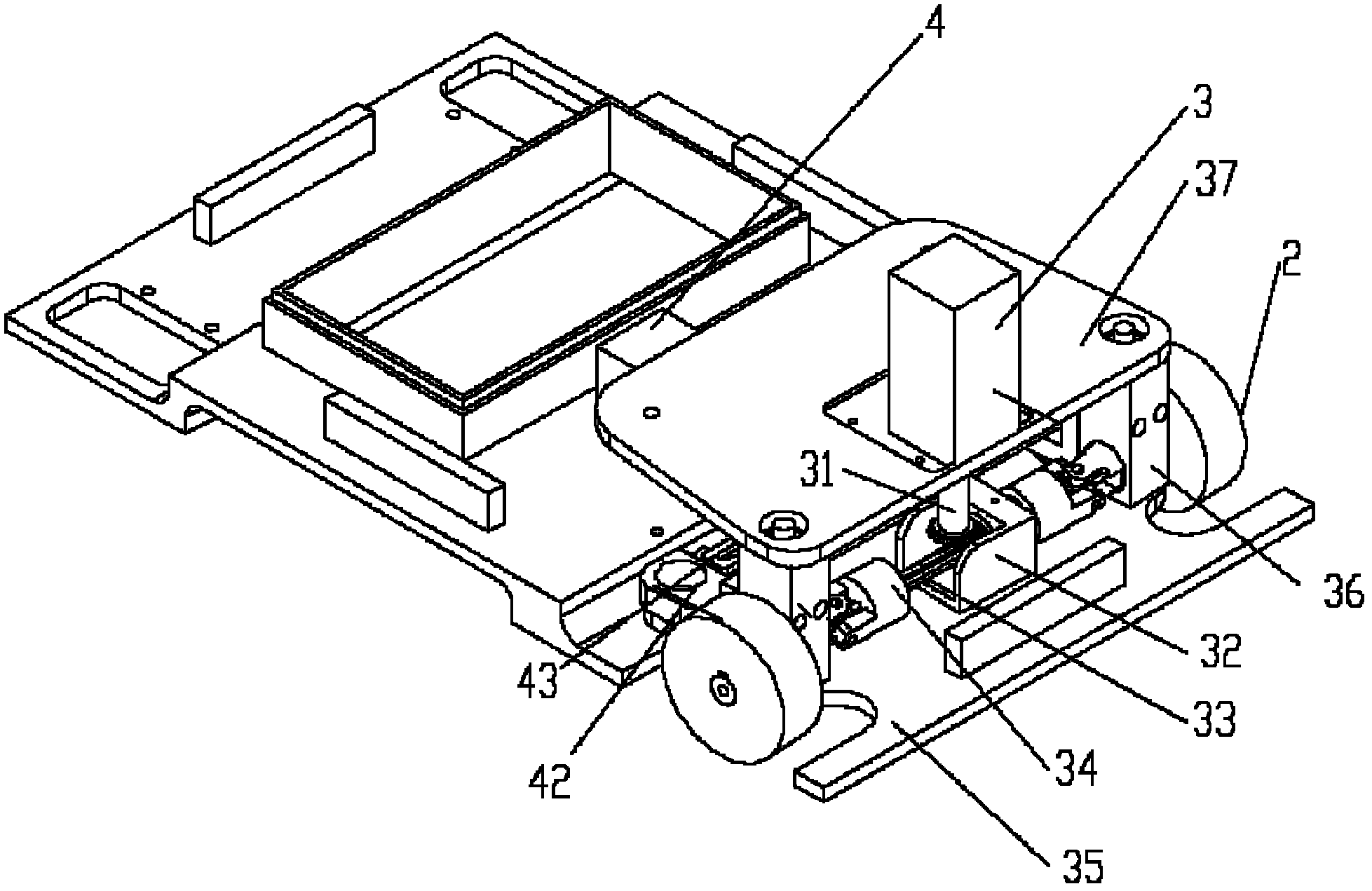

[0046] A single-gun double-wire high-speed fully automatic gas shielded welding robot, comprising a robot walking trolley body 1 and a magnetic wheel 2, and a trolley movement system, a trolley steering system, an X-axis correction device and A Z-axis correction device, the trolley movement system is connected to the magnetic wheel 2, and a welding gun 7 is provided on the Z-axis correction device.

[0047] The trolley movement system includes a trolley drive motor 3, a trolley drive shaft 31, a power restraining body 32, a spline shaft 33, a cardan shaft 34, a bottom plate 35, a rotating frame 36, and a motor seat 37. The trolley drive motor 3 is connected to the trolley drive shaft 31. The trolley drive shaft 31 is connected to a spline shaft 33 through a bevel gear. The spline shaft 33 is arranged in the power restraining body 32. Both ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com