Multistage anaerobic/anoxic/oxic activated sludge process

An activated sludge method, anoxic and aerobic technology, applied in aerobic and anaerobic process treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of increasing operation and management costs, synchronizing biological It is difficult to achieve a high level of phosphorus removal efficiency, and the volume of biological pools is small, so as to reduce the amount of excess sludge, solve the contradiction between denitrification and phosphorus removal, and save carbon sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Achieve enhanced denitrification

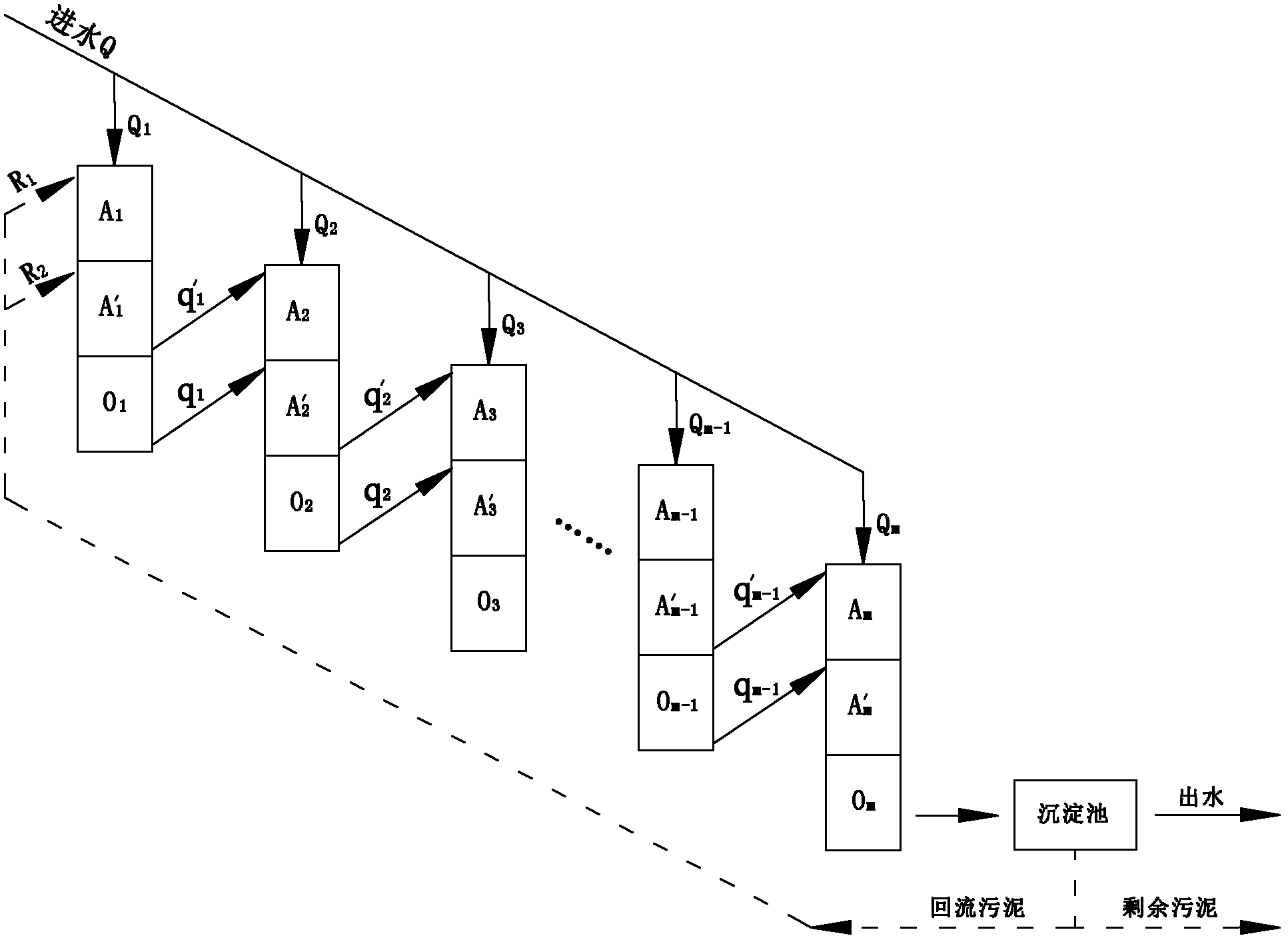

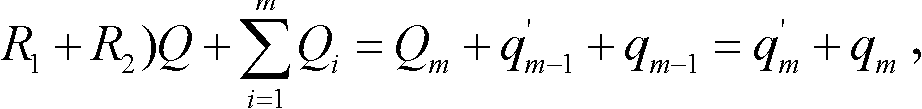

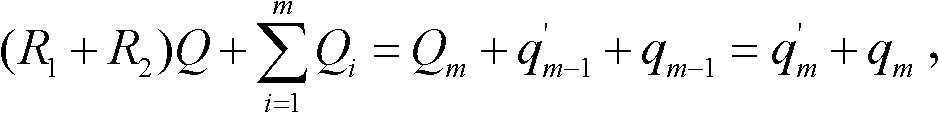

[0048] The multi-stage anaerobic-anoxic-aerobic activated sludge process (MAAO) of the present invention is made up of four-stage anaerobic-anoxic-aerobic (AA'O), and each stage of AA'O consists of an anaerobic pool A, an anaerobic tank A Oxygen pool A' and an aerobic pool O are connected to each other in turn; sewage is equal flow rate Q 1 =Q 2 =Q 3 =Q 4 = 25% Q is sequentially distributed into the head end of the anaerobic tank at all levels, the total sludge return ratio is 100%, and part of the sludge return ratio is R 1 =70% return to the first stage anaerobic tank (A 1 ), the remaining sludge return ratio R 2 = 30% return to the first stage anoxic pool A' 1 . The total amount of mixed liquid in the anoxic tanks at all levels is 1.25Q, 1.5Q, 1.75Q, 2.0Q respectively. First tertiary anoxic pool mixture, part q 1 =Q,q 2 =1.25Q,q 3 = 1.25Q After the nitrification reaction is completed in the aerobic tank of this level, it ...

Embodiment 2

[0050] Realize enhanced denitrification and phosphorus removal

[0051] The multi-stage anaerobic-anoxic-aerobic activated sludge process (MAAO) of the present invention is made up of four-stage anaerobic-anoxic-aerobic (AA'O), and each stage of AA'O consists of an anaerobic pool A, an anaerobic tank A Oxygen pool A' and an aerobic pool O are connected to each other in turn; sewage is equal flow rate Q 1 =Q 2 =Q 3 =Q 4 = 25% Q is sequentially distributed into the head end of the anaerobic tank at all levels, the total sludge return ratio is 100%, and part of the sludge return ratio is R 1 = 70% return to the first stage anaerobic tank A 1 , the return ratio of the remaining sludge is R 2 = 30% return to the first stage anoxic pool A' 1 . The total amount of mixed liquid in the anoxic tanks at all levels is 1.25Q, 1.5Q, 1.75Q, 2.0Q respectively. Mixture of first three anoxic tanks, a part of q' 1 =Q,q' 2 = 1.25Q, q' 3 = 1.5Q directly enters the lower anaerobic tank f...

Embodiment 3

[0053] Low oxygen aeration energy saving operation

[0054] The above two implementations are implemented under the same working conditions. The aerobic tanks at all levels implement low-oxygen aeration, and the dissolved oxygen is between 0.2-1.0mg / l, which further saves aeration energy consumption and reduces operating costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com