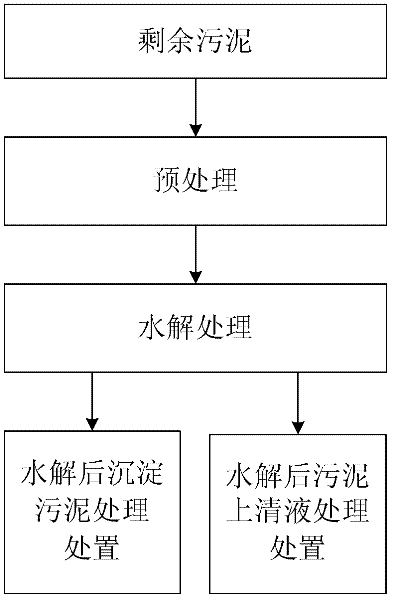

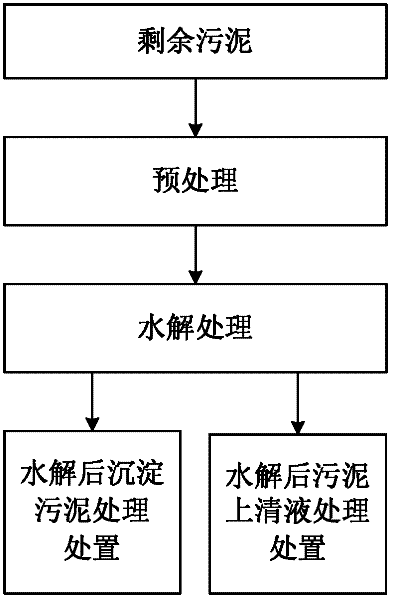

Treatment method for excess sludge

A technology for excess sludge and treatment methods, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve problems such as high cost and easy secondary pollution, and achieve cost The effect of low cost and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] This embodiment provides a method for treating surplus sludge. The detection indicators of the surplus sludge processed are as follows: sludge moisture content=99.3%, SV 30 =98%, MLSS=5650mg / L, MLVSS=3616mg / L; sludge supernatant COD=22.1mg / L, BOD 5 = 13.48 mg / L.

[0047] The specific processing steps are as follows:

[0048] (1) Pretreatment: send the remaining sludge to the sludge thickening tank for gravity concentration, reducing the moisture content of the sludge to about 98.7%;

[0049] (2) Hydrolysis treatment: the sludge pretreated in step (1) is sent to a closed reaction vessel, and the sludge is hydrolyzed under 4MPa pressure and 200 degrees Celsius to transfer most of the organic matter in the sludge to In the sludge water, the quality of the sludge solids is greatly reduced, and the pathogens in the sludge are killed under the reaction conditions;

[0050] (3) Sedimentation treatment: After the sludge in step (2) is precipitated for 30 minutes, the supernatant liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com