Method for firing art ceramic products

A technology of artistic ceramics and products, applied in the field of ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0029] [0028 Embodiment 1, a kind of firing method of art ceramics, concrete steps are as follows:

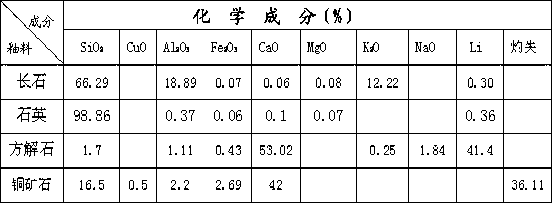

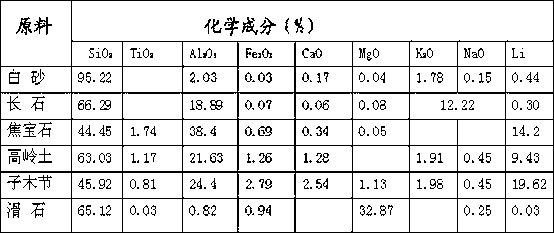

[0030] (1) Raw material ingredients

[0031] a. Material preparation: pick out the stones, iron and other impurities mixed into the raw materials, according to the ratio of the raw material formula: white sand 15%, feldspar 5%, burnt gemstone 6%, kaolin 50%, sub-wood knot 20%, talc 4%, accurately weigh all kinds of required raw materials, the chemical composition of each raw material is shown in Table (1), put it into the wet ball mill, ball stone: raw material: water=1.6~2.0:1:0.4~0.45;

[0032] B, grinding: determine grinding time and slurry fineness according to formula requirement fineness, 16~20 hours / mill, mud fineness is to pass through 100 mesh sieves...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com