Method for synthesizing dimer acid type polyamide hot melt adhesive

A polyamide hot-melt adhesive, dimer acid type technology, applied in the direction of adhesives, etc., can solve the problems of complex synthesis process, limited raw materials, poor compatibility, etc., and achieve the effects of easy chemical equivalent, stable product production, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

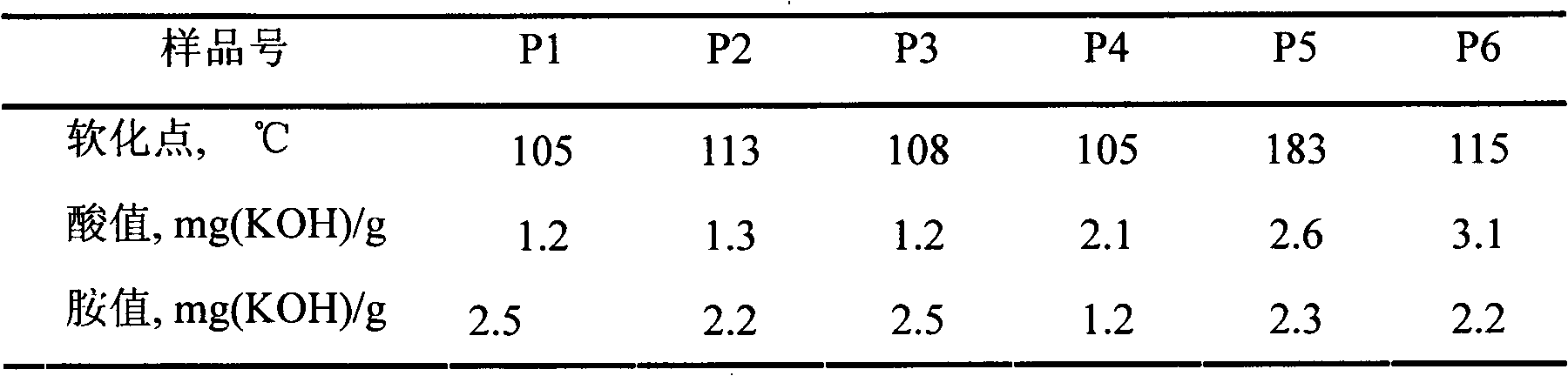

Examples

Embodiment 1

[0018] In the high-pressure reactor of 2000ml, drop into 678 grams of dimer acid (British Croda Company, Pripol1006), hexamethylenediamine 139.6g, 20% ethanol aqueous solution 250g, 1010 antioxidant 0.9g and stearic acid 2.0g, in 2.0h Internally raise the temperature to 250°C, as the temperature rises, when the pressure in the reactor reaches 1.0MPa, keep the reaction for 1h, then reduce the pressure of the reactor to normal pressure within 2h, and keep the normal pressure for 1h, then pass nitrogen Pressurize to 0.2MPa, discharge, and get product P1

Embodiment 2

[0020] In the high-pressure reactor of 2000ml, drop into 649.8 grams of dimer acid (British Croda Company, Pripol1006), sebacic acid 10.1g, hexamethylenediamine 139.6g, 33% ethanol aqueous solution 300g, 1010 antioxidant 0.3g and stearic acid 1.5g, heat up to 250°C within 2.5h, keep the reaction for 1h when the pressure in the reactor reaches 1.5MPa, then reduce the pressure of the reactor to normal pressure within 2h, and keep the normal pressure for 1h, add nitrogen Press to 0.2MPa, discharge, and get product P2

Embodiment 3

[0022] In the high-pressure reactor of 2000ml, drop into 628.2 grams of dimer acid (British Croda Company, Pripol1006), adipic acid 7.8g hexamethylenediamine 139.6g, water 200g, ethanol mixed solution 100g, 1010 antioxidant 0.3g and stearin Acid 2.0g, heat up to 250°C within 3.0h, keep the reaction for 1h when the pressure in the reactor reaches 1.8MPa, then reduce the pressure of the reactor to normal pressure within 3h, and keep the normal pressure for 1h, pass nitrogen Pressurize to 0.2MPa, discharge, and get product P3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com