Bi-phthalonitrile prepolymer as well as preparation method and application thereof, bi-phthalonitrile prepolymer/epoxy resin copolymer and preparation method thereof as well as bi-phthalonitrile prepolymer/epoxy resin cured material

A technology of curing diphthalonitrile and epoxy resin, applied in the direction of organic chemistry, etc., to achieve the effect of easy realization, easy control and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

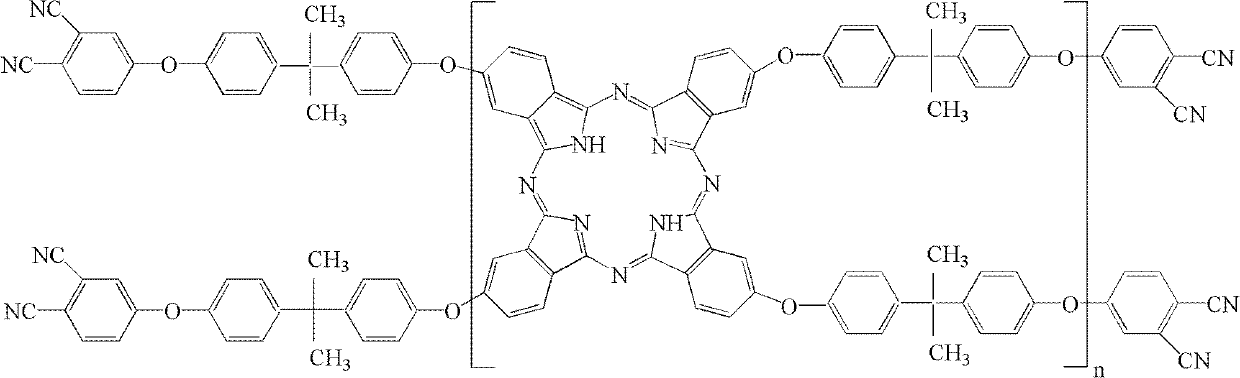

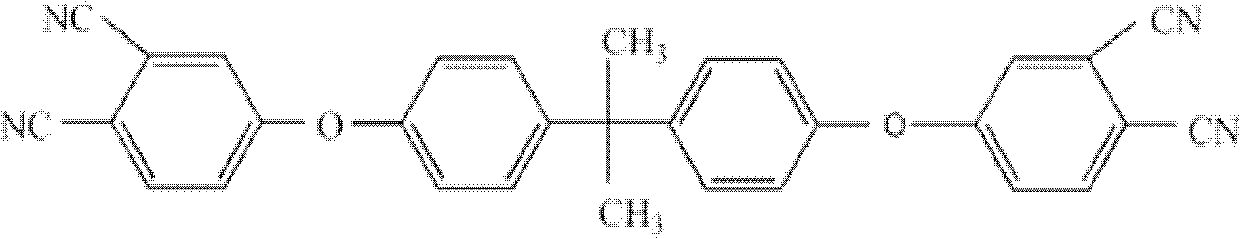

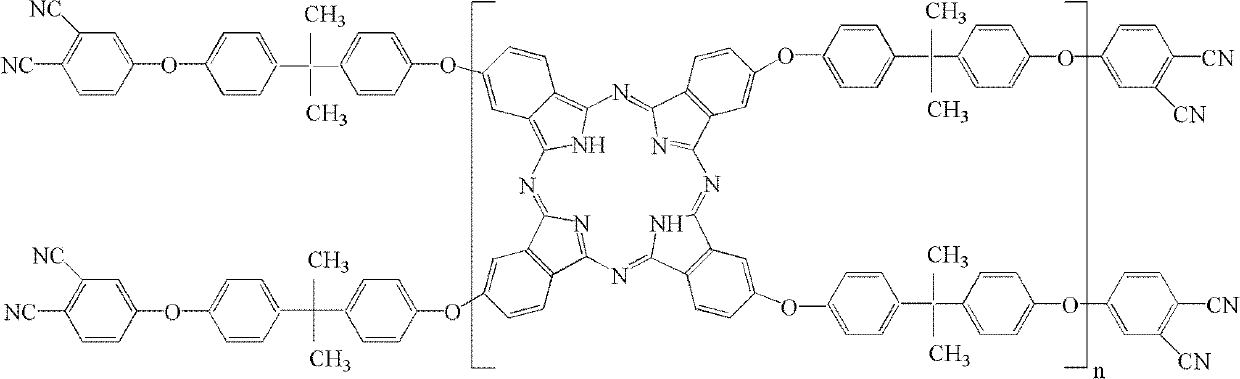

Image

Examples

Embodiment 1

[0042] Embodiment 1 Preparation of bisphthalonitrile prepolymer / epoxy resin cured product

[0043] (1) melting the bis-phthalonitrile monomer at 190° C., and prepolymerizing for 15 minutes to obtain a bis-phthalonitrile prepolymer;

[0044] (2) Mix 4,4'-diaminodiphenylsulfone and epoxy resin E-44, and then melt blend with the bisphthalonitrile prepolymer prepared in step (1) at 190-200°C Make bis-phthalonitrile prepolymer / epoxy resin copolymer, wherein the weight ratio of bis-phthalonitrile prepolymer and epoxy resin is as shown in Table 1, 4,4'-diaminodiphenyl sulfone The consumption of the epoxy resin is 27wt%.

[0045] (3) The bisphthalonitrile prepolymer / epoxy resin copolymer obtained in step (2) is poured and heat-treated to obtain a self-flame-retardant bisphthalonitrile prepolymer / epoxy resin cured product Wherein, the temperature of heat treatment is 190 ℃ / 4h, 210 ℃ / 2h, 230 ℃ / 2h, 250 ℃ / 2h, 270 ℃ / 2h; The flammability is shown in Table 1.

Embodiment 2-5

[0046] Embodiment 2-5 Preparation of bisphthalonitrile prepolymer / epoxy resin cured product

[0047] The preparation method of embodiment 2-5 is the same as that of embodiment 1, and the ratio of raw materials is different from that of embodiment 1, wherein the weight ratio of bisphthalonitrile prepolymer and epoxy resin is as shown in table 1, and the obtained bisphthalonitrile The flame retardant performance of the prepolymer / epoxy resin cured product is shown in Table 1.

[0048] In the present invention, the UL-94 vertical combustion test adopts the GB / T 2408-2008 standard, and the sample size is 125×13.0×3.0mm 3 ; The oxygen index test adopts the GB / T 2406-93 standard, and the sample size is 130×6.5×3mm 3 .

[0049] Table 1 Raw material ratio and properties of bisphthalonitrile prepolymer / epoxy resin cured product

[0050]

[0051] In Table 1, NR stands for no grade, which is a flammable material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial decomposition temperature | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com