Control system for pulverized coal making of pulverized coal injection

A control system, pulverized coal injection technology, applied in blast furnace parts, furnaces, blast furnace details, etc., can solve the problems of low degree of automation, lack of overall control, difficulty in reaching target values, etc., to improve the smelting process, promote The effect of blast furnace antegrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

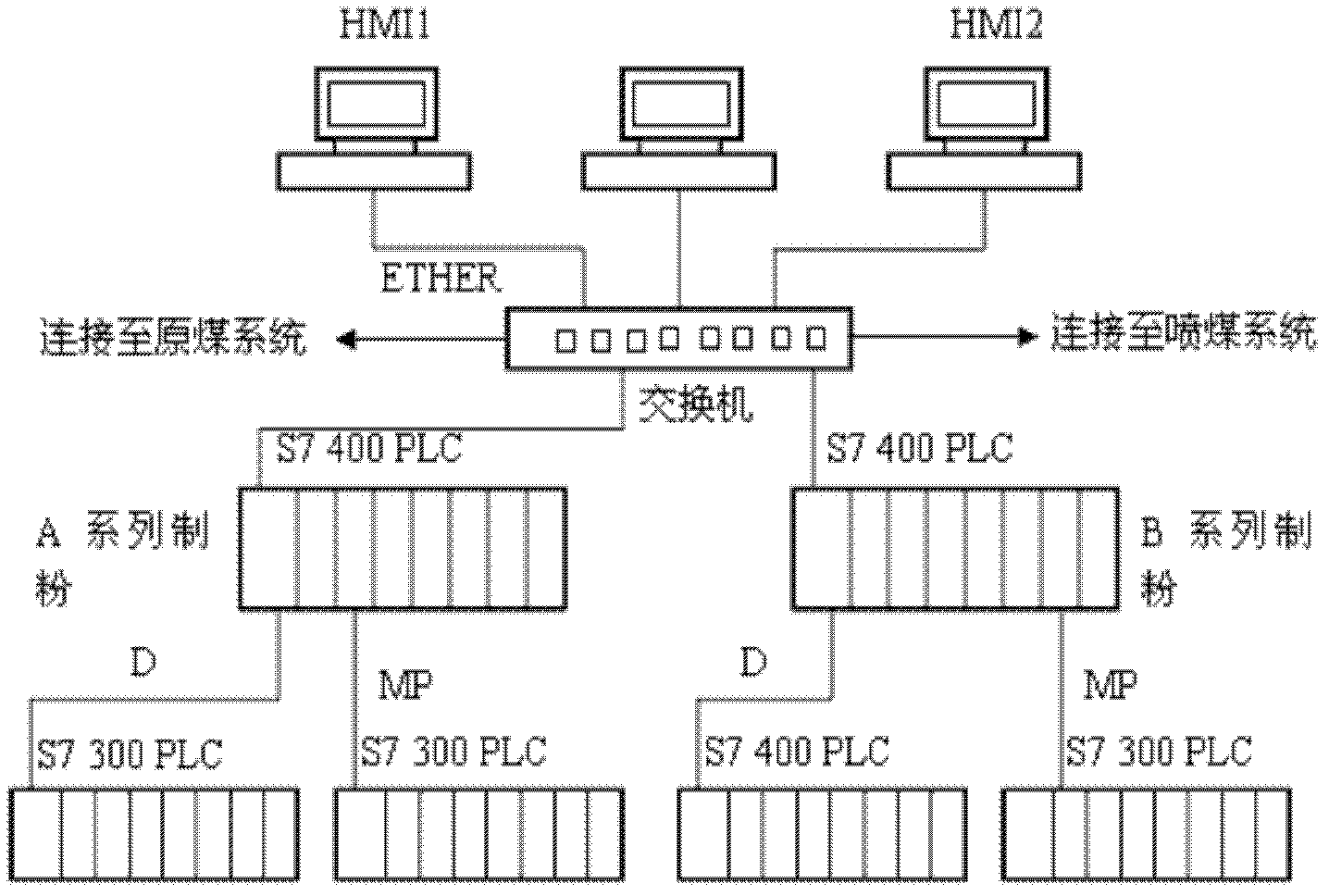

[0026] figure 1 It is the equipment layout diagram of the pulverizing control system. The hardware system of the pulverizing system mainly includes two sets of Siemens S7 400PLC, S7 300PLC (one set for A and B series), 3 sets of industrial computers, network system, remote I / O station and other related equipment.

[0027] Each milling series includes Siemens S400PLC central rack, Siemens S300PLC rack and related functional templates, SITOP power supply, remote station, OLM photoelectric converter and required switches, terminals and other accessories.

[0028] SIMATIC S7-400 is a powerful PLC, suitable for medium and high performance fields, able to meet complex task requirements, easy to implement distributed systems and expand communication capabilities, flexible and free to form systems, fully able to meet the needs of coal injection and pulverization systems Control requirements.

[0029] The S7-400 of each series of coal pulverization system uses a main rack and four ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com