Construction method of backfill in layers for sea reclamation

A technology for reclaiming land from the sea and dredging and reclamation. It is applied in the direction of filling water and building land. It can solve the problems of many hidden dangers, difficult to determine the construction period, increase costs, etc., and achieve the effect of reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

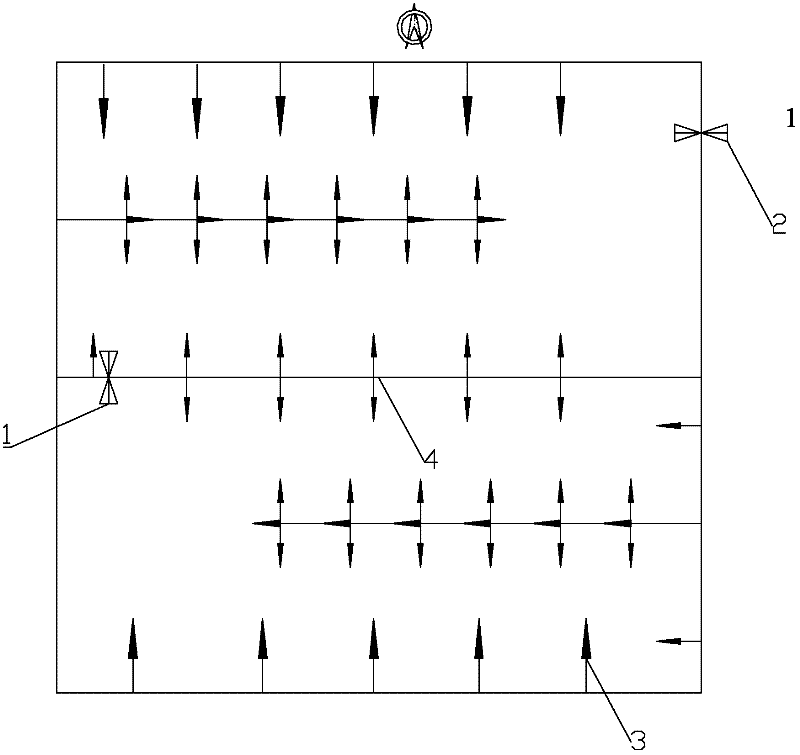

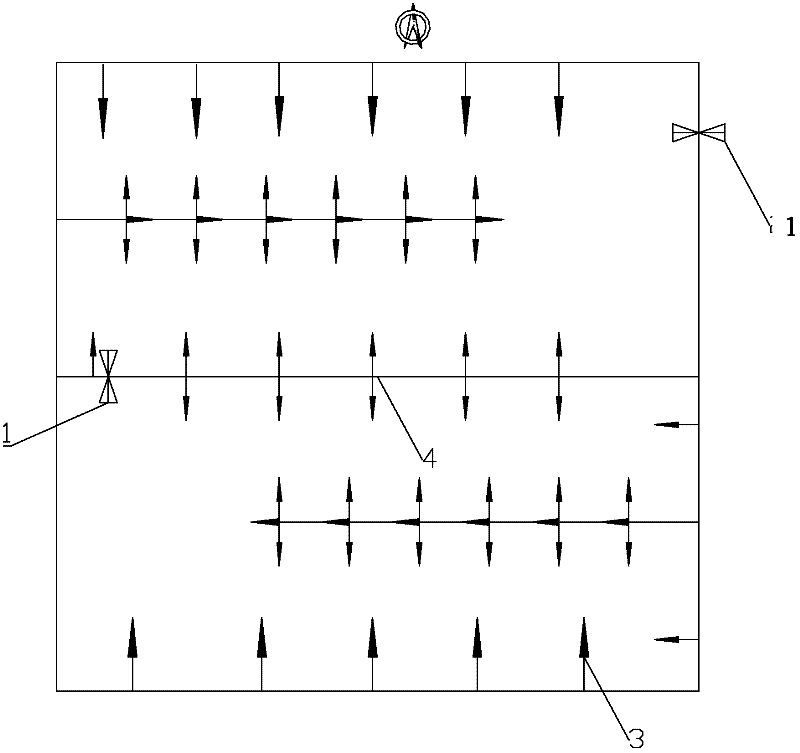

[0018] The layered mud blowing construction method for sea reclamation and land reclamation of the present invention will be described in conjunction with the accompanying drawings and examples.

[0019] In the layered mud blowing construction method for land reclamation provided by the present invention, a middle partition is set in the middle of the reclamation area to divide the reclamation area into two equal-sized south and north areas to organize layered flowing water dredging respectively. The filling is carried out from east to west, and from west to east in the north area; the construction method includes the following steps:

[0020] 1. Construction process

[0021] Partition partition construction → discharge outlet setting → mud pipe layout → dredger stationing → partition flow water filling the first layer → partition flow water filling the second floor → surface water removal → end

[0022] 2. Partition and flow direction of blow filling

[0023] The dredging r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com