Production method of fiber cement-stone compound plate and product thereof

A technology of fiber cement and production method, applied in the direction of covering/lining, building, building structure, etc., to achieve the effect of high bending strength, easy laying and installation, and good environmental aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

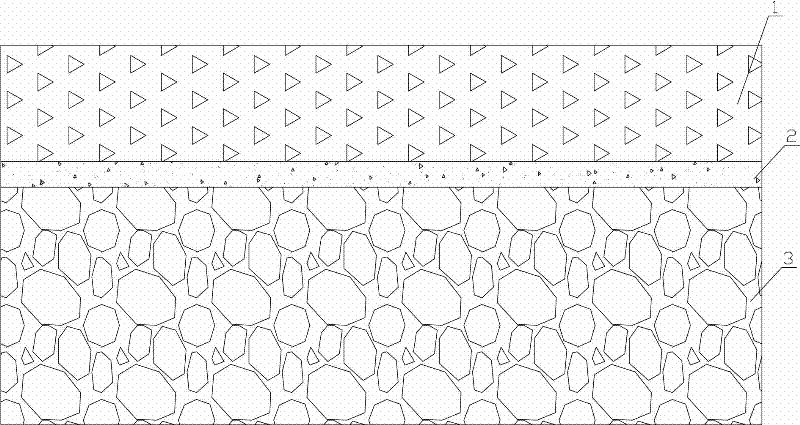

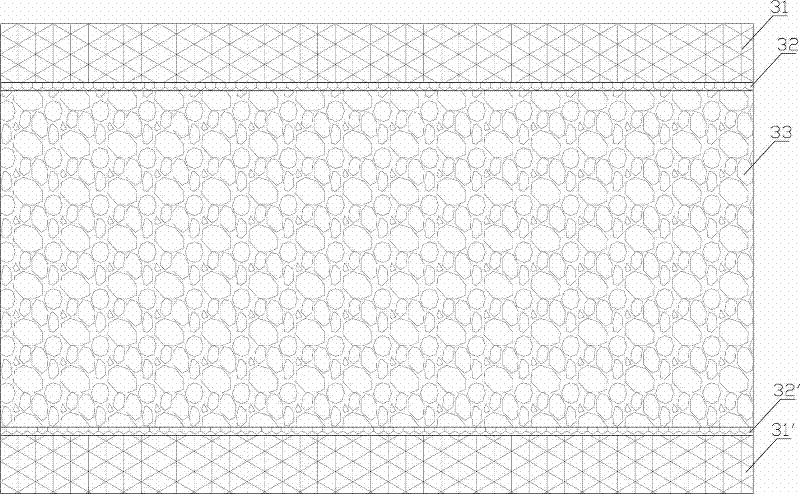

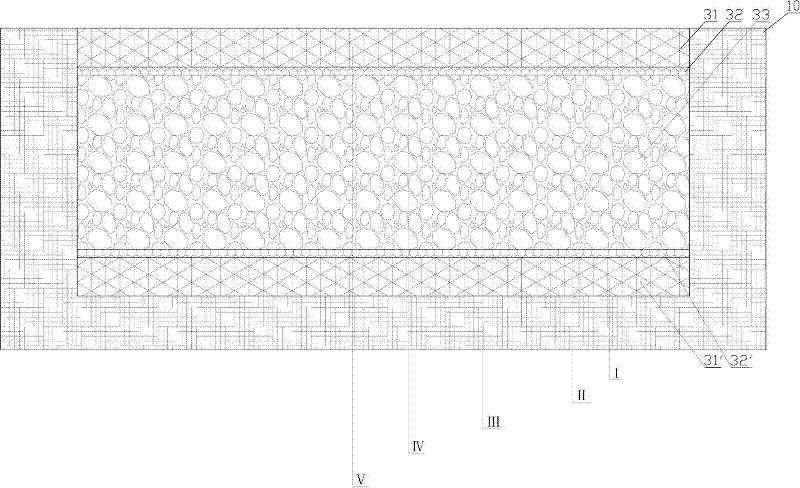

[0036] Stone composite panel of the present invention, as figure 1 As shown, it is composed of a stone panel 1 and a base plate 3 including cement components, through a bonding layer 2 including viscosity-modified cement as a bonding material, and then pressed and composited. Composite panels. The stone constituting the panel 1 can be granite, marble or marble decorative board, its surface 11 is polished, and its back side 12 will be roughened, or several lengths and widths are engraved on the back side 12 and are (0.5~0.8 )mm groove line.

[0037] At the same time, prepare the mixed cementitious material that constitutes the bonding layer 2, including high-strength and fast-hardening 2.5Mpa cement, as the main material, such as sulphoaluminate cement, and add a polyacrylate aqueous solution with a weight of 40% to 50% of the cement. , the concentration of the aqueous solution is 2% to 5%, and it is stirred into a slurry, so that the viscosity-modified cement slurry can incr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com