Shield tunneling machine for underground pipeline

A technology of underground pipelines and shield machines, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

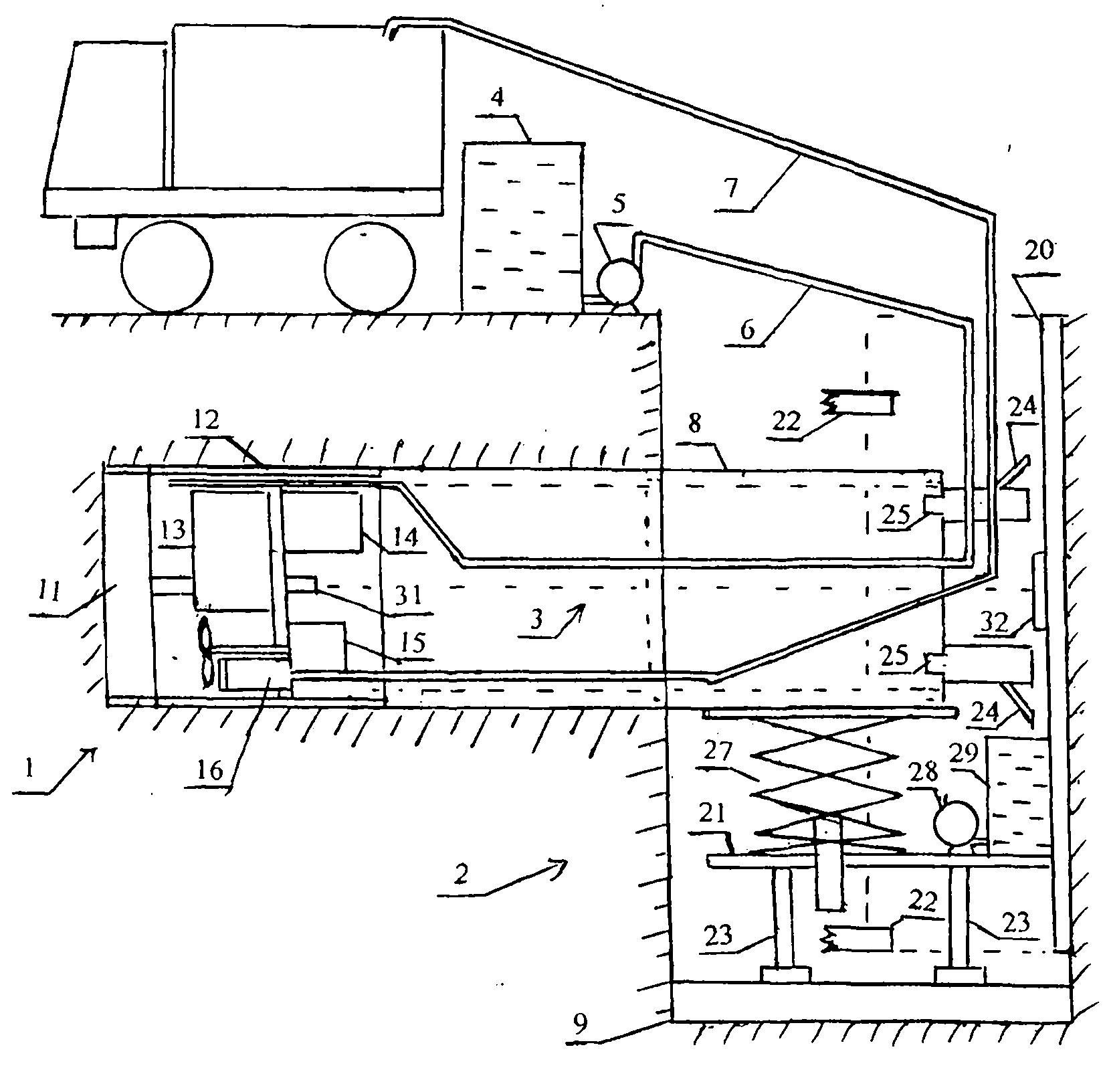

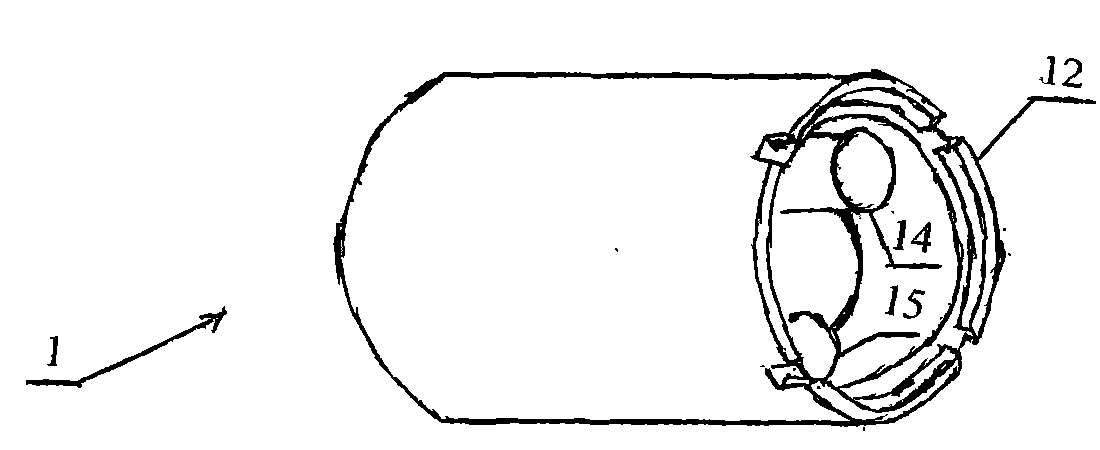

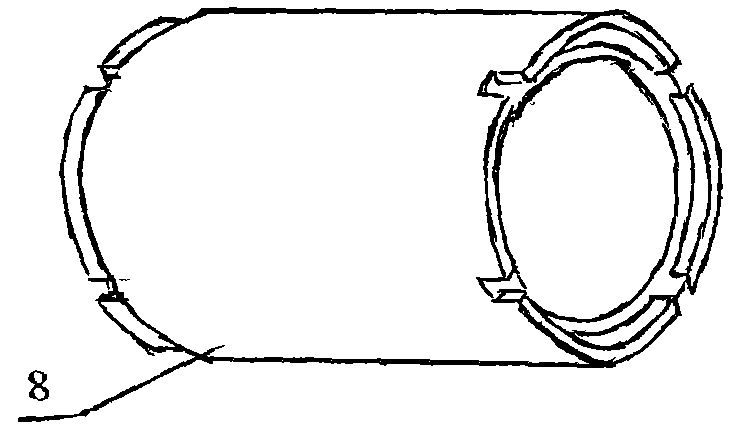

[0014] figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, the underground pipeline shield tunneling machine of the present invention is composed of a shield machine 1, a water pump 3, a water tank 5, a hydraulic propulsion device 2 and a computer control system. The shield machine 1 is composed of a cutter head 11 , a shield 12 , a motor 14 , a gear box 13 , a mixer 15 and a sludge pump 16 . The motor 14 drives the cutter head 11 to rotate after being decelerated by the gears of the gear box 13 . The water pump 4 outside the hole draws water from the water tank 5 and enters the shield machine 1 through the water pipe 6 to spray to the upper part of the cutter head 11 to cool the cutter head 11 and flush the sludge on the cutter head 11. The mixer 15 stirs the sludge evenly, crushes the stones, and scrapes off the large sandstones on the filter screen at the inlet of the sludge pump 16. Sludge pump 16 is contained in the below of gear box 13, and sludge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com