Multidimension measuring apparatus of high speed processing handle

A measuring device and multi-dimensional technology, which is applied in the field of mechanical engineering, can solve the problems of low measurement efficiency and low measurement accuracy, and achieve the effect of improving measurement accuracy, high measurement accuracy and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

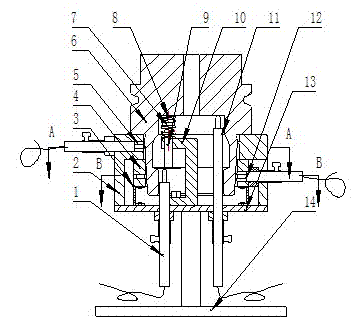

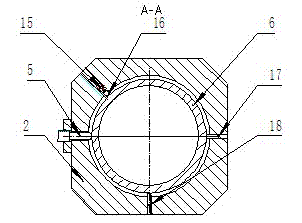

[0033] The device of the present invention is composed of a base 14, a sensor A1, a sensor B5, a sensor C11, a sensor D12, a large end diameter measuring ring 2, a small end diameter measuring 4, a supporting sheet spring 3, and clamping inclined plane measuring disc rods 9. components.

[0034] Taking the tool handle measurement of the HSK63A model as an example, the four dimensions of the HSK63A calibration gauge produced by a professional manufacturer are:

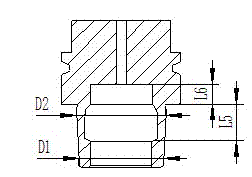

[0035] D1=46.537; D2=48.010; L5=18.13; L6=9.94

[0036] The invention can simultaneously measure the four main dimensions D1, D2, L5 and L6 of the HSK63A tool holder and transmit them to the computer.

[0037] Such as figure 2 As shown, the device of the present invention is composed of a base 14, a sensor A1, a sensor B5, a sensor C11, a sensor D12, a large end diameter measuring ring 2, a small end diameter measuring 4, a support plate spring 3, and a clamping inclined plane measuring disc rod 9 and other main com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com