Interface circuit of differential capacitance micro vibrating sensor

A vibration sensor and interface circuit technology, applied in the field of differential tolerance micro-vibration sensor interface circuit, can solve the problem of not being able to satisfy accuracy, stability and flexibility at the same time, improve anti-interference ability, eliminate the influence of measurement accuracy, temperature drift Low coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. This embodiment provides detailed implementations based on the technical solution of the present invention, but the scope of protection of the present invention is not limited to the following embodiments.

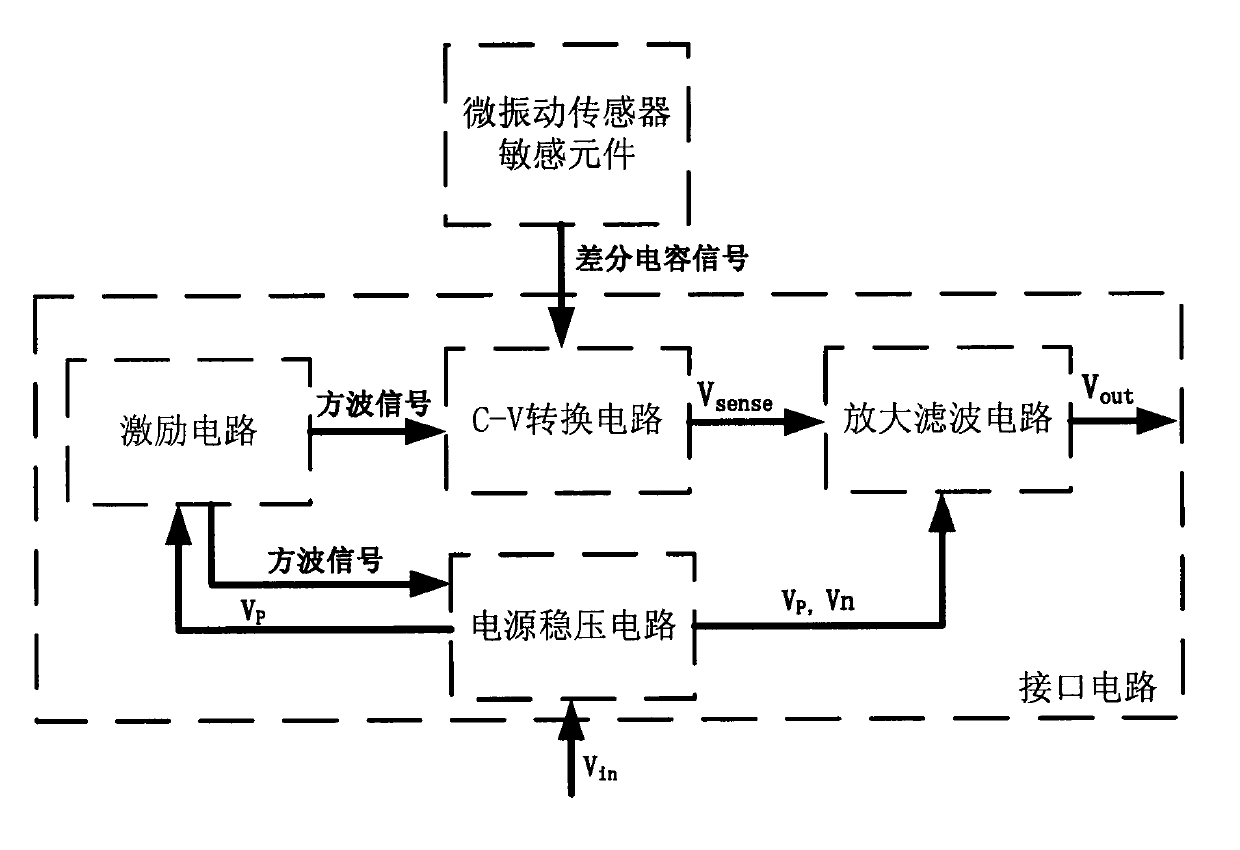

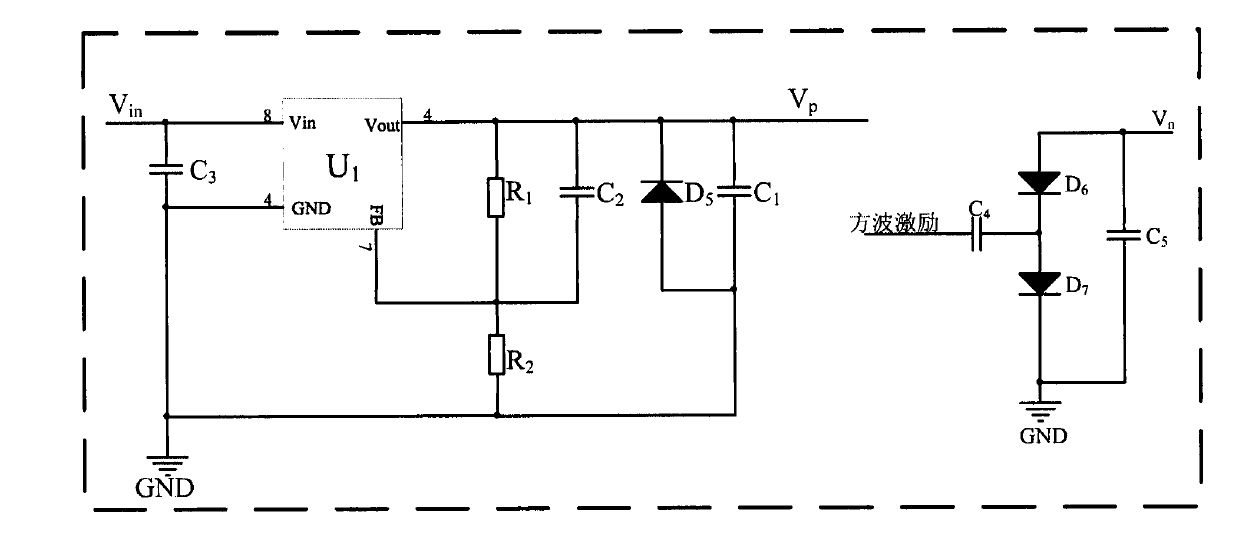

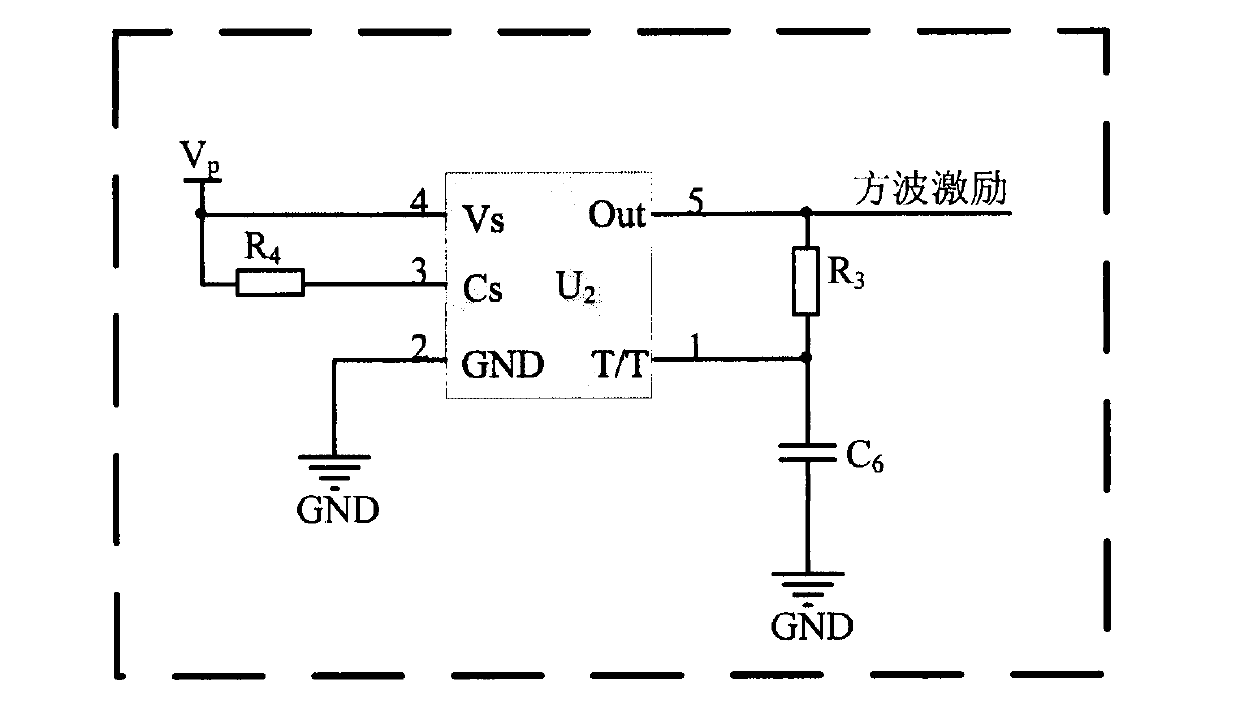

[0034] Such as figure 1 Shown is the functional block diagram of the micro-vibration sensor interface circuit of the present invention. It can be seen from the figure that the interface circuit power supply voltage stabilization circuit, square wave excitation circuit, C-V conversion circuit, amplification filter circuit and micro-vibration sensor sensitive components, wherein the power supply voltage stabilization circuit takes the external power input V in converted into a stable positive supply V p , respectively supply power to the square wave excitation circuit, C-V conversion circuit, amplification filter circuit and micro-vibration sensor sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com