Alternating current frequency conversion control method suitable for vibrating stress relief

An AC frequency conversion and control method technology, applied in the field of frequency conversion control, can solve the problems such as the inability to obtain the high-order harmonic amplitude and phase of the motor, the inability to determine the output voltage increment coefficient, and the inability to achieve, so as to improve the CPU processing speed, The effect of increasing the steady speed and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

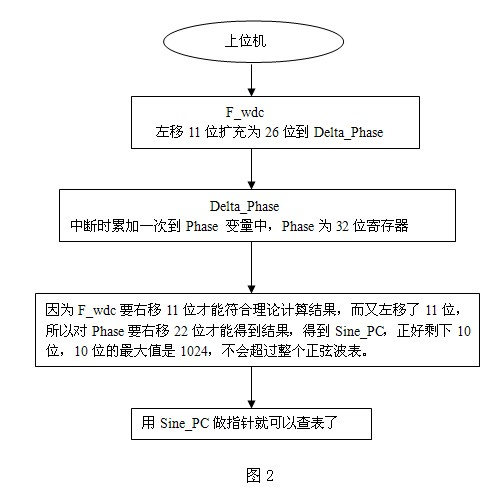

[0020] The AC frequency conversion control method suitable for vibration aging of the present invention mainly improves the stable speed of the single-chip microcomputer by changing the calculation method of the single-chip microcomputer, so that the stable speed accuracy of the motor reaches ±1rpm; in order to simplify the circuit and reduce costs, the present invention adopts software. Control, combined with the characteristics of vibration time-sensitive equipment, using the register shift method to automatically check the function baud table in the frequency conversion control to output the drive square wave of the power module IGBT, which saves a lot of resources for the calculation of the sine function of the single-chip microcomputer. The CPU processing speed has been improved, and the steady speed has been greatly improved.

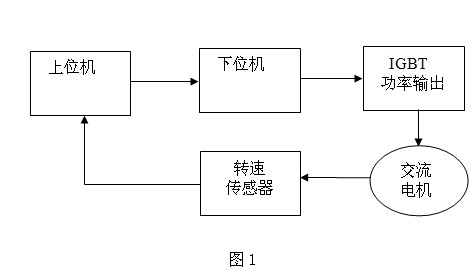

[0021] figure 1The AC frequency conversion control principle of the present invention is given. The power module (IGBT) is controlled by the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com