Atmospheric pressure optical plasma brush-type device and electric discharge method thereof

A plasma brush and atmospheric pressure technology, applied in the field of plasma, can solve problems such as unseen applications, and achieve the effects of controllable discharge area, simple discharge method, and low cost of discharge equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

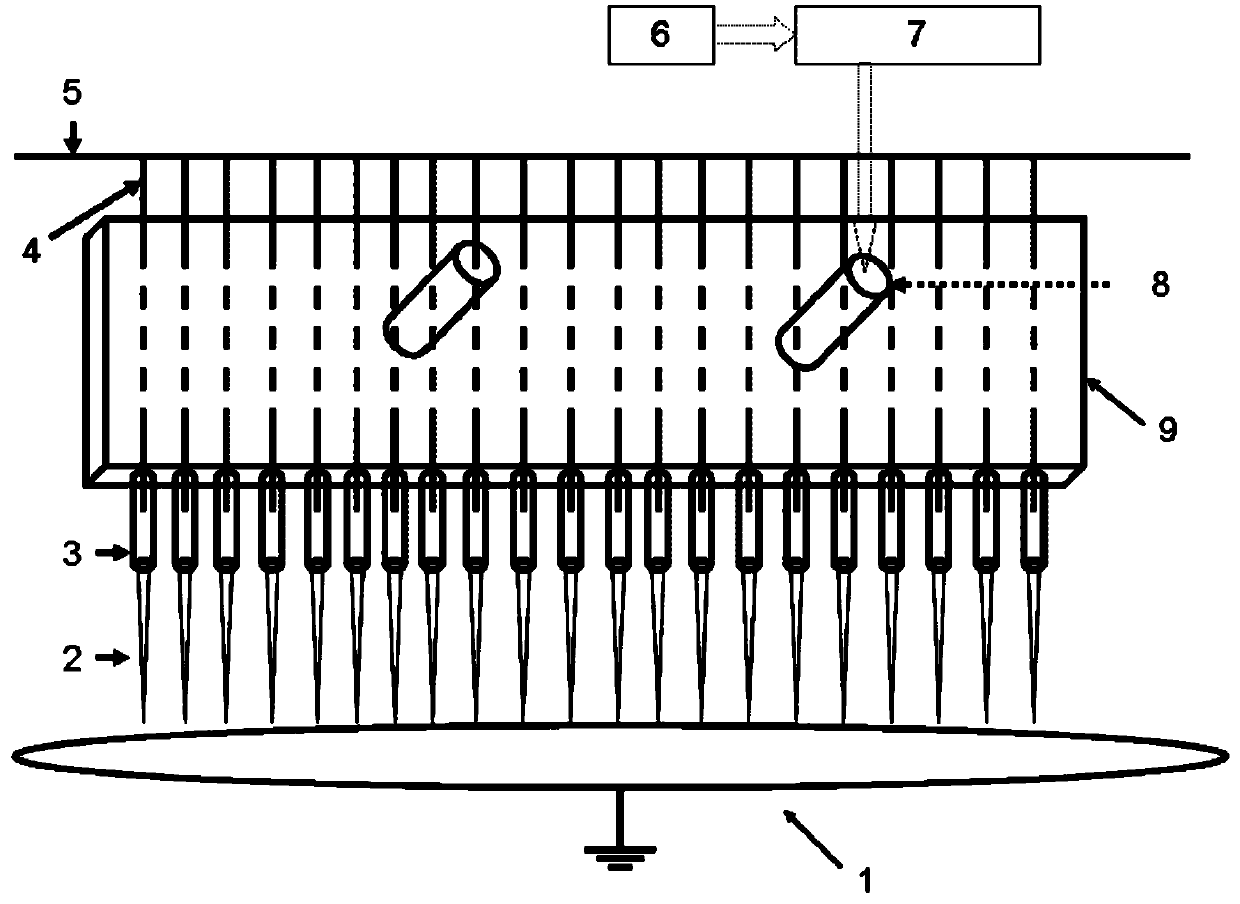

[0029] Atmospheric pressure fiber optic plasma brush devices, such as figure 1 As shown, it includes a high-voltage AC power supply 5, an air cavity 9, a group of microporous optical fibers 3 and corresponding high-voltage electrodes 4 and a ground electrode 1;

[0030] The high-voltage electrode 5 is connected to a high-voltage AC power supply 5, and a high-voltage electrode 5 is correspondingly inserted into a microporous optical fiber 3;

[0031] The micro-hole optical fiber 3 is evenly arranged in parallel and fixed in the air cavity 9; the air cavity 9 is provided with a small hole matching the outer diameter of the optical fiber corresponding to the discharge end of the micro-hole optical fiber 3;

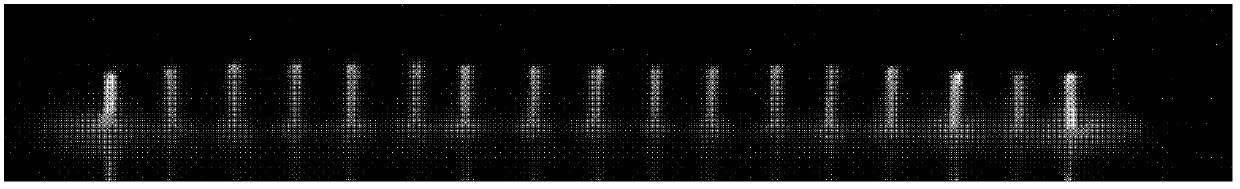

[0032] Described microhole optical fiber 3 has through hole, and its outer diameter is 1mm, and inner diameter is 50 μ m; The discharge end of microhole optical fiber 3 passes outside the air cavity 9 through the aperture of described air cavity; The quantity of microhole opt...

Embodiment 2

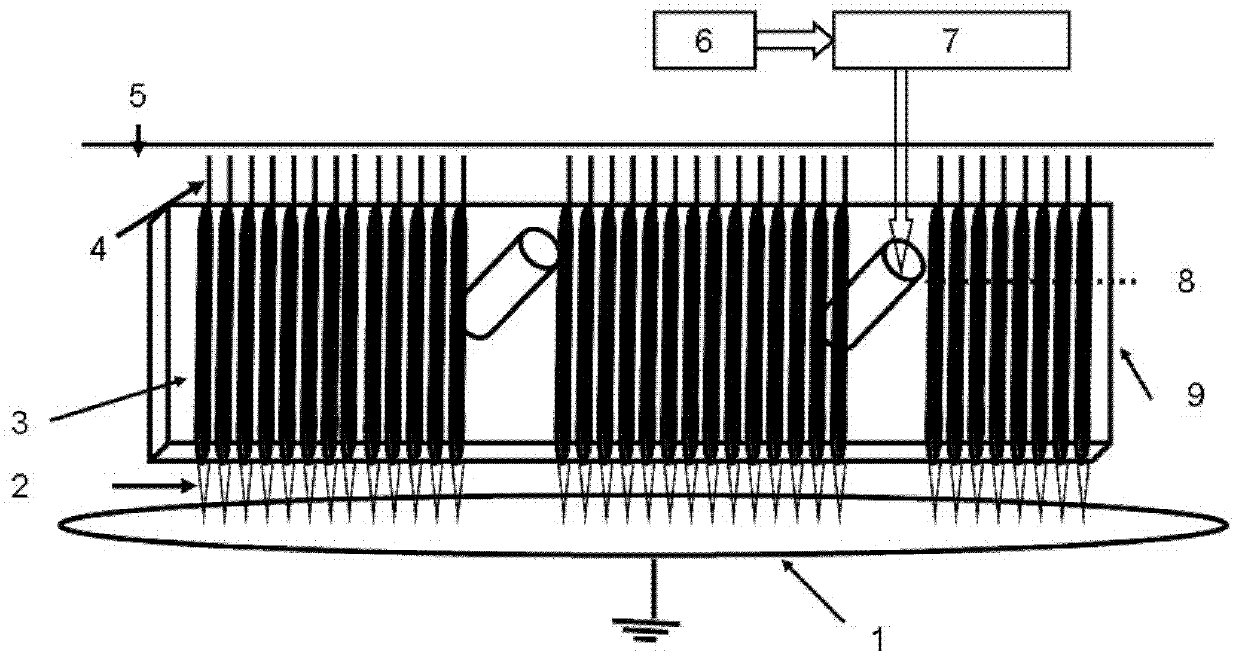

[0039] Another atmospheric-pressure fiber optic plasma brush device, such as image 3 As shown, it is different from Embodiment 1 in that the microhole fiber 3 has a blind hole, that is, its discharge end is closed, then the microhole fiber 3 is placed in the air cavity 9, and its discharge end is in the air cavity 9. The air cavity is close to the small hole in the air cavity; the power supply 5 is turned on for a period of time, and the gas passes through the outer surface of the optical fiber 3 with blind holes, and discharges at its closed end; thereby generating a uniform and dense atmospheric pressure plasma with a controllable area Body 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com