Method for charging/discharging positive electrode active material in a lithium secondary battery, charging/discharging system provided with lithium secondary battery and vehicle, electronic device, battery module, battery pack

一种正极活性物质、锂二次电池的技术,应用在二次电池充电/放电、二次电池、二次电池制造等方向,达到高容量、高充放电可逆性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0056] Next, a first embodiment of the present invention will be described. This embodiment is a charging and discharging method for a positive electrode in a lithium secondary battery. The lithium secondary battery includes: a positive electrode containing a positive electrode active material, a negative electrode containing a negative electrode active material capable of absorbing and releasing lithium, and a battery arranged between the positive electrode and the negative electrode. between the separator, and the non-aqueous electrolyte.

[0057] The positive electrode active material in this embodiment is a nickel-based lithium-containing composite oxide capable of storing and releasing lithium. Examples of nickel-based lithium-containing composite oxides include LiNiO 2 As a base, a material in which part of Ni is replaced by another element selected from Mg, Sc, Y, Mn, Fe, Co, Ni, Cu, Zn, Al, Cr, Pb, Sb, and B.

[0058] In addition, in the present embodiment, the end-o...

Embodiment 1

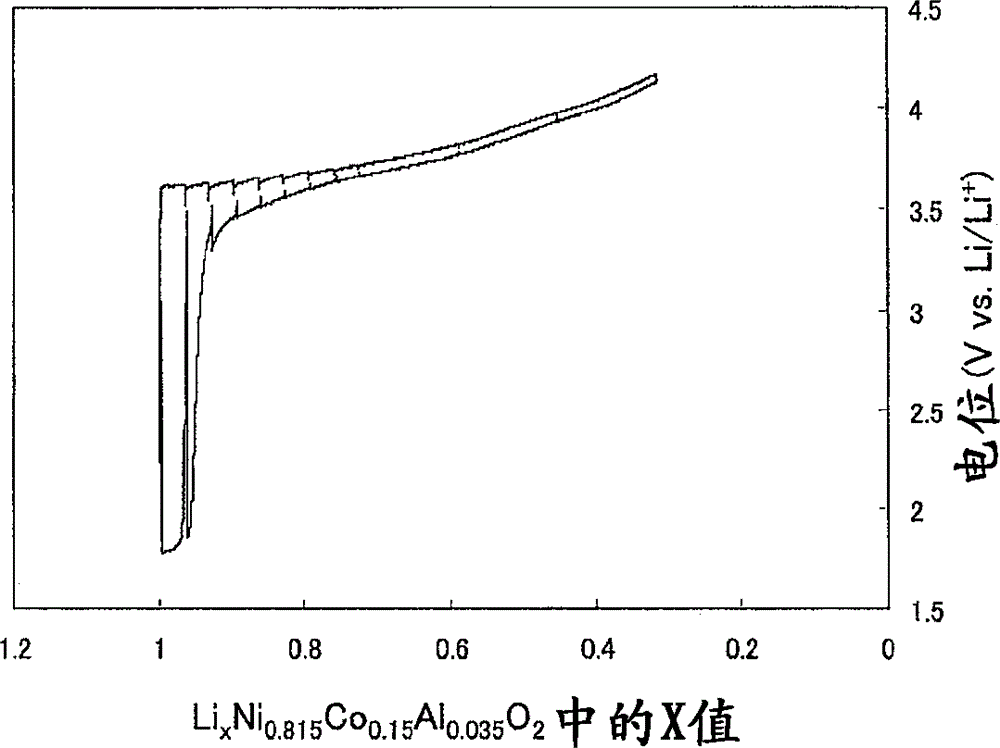

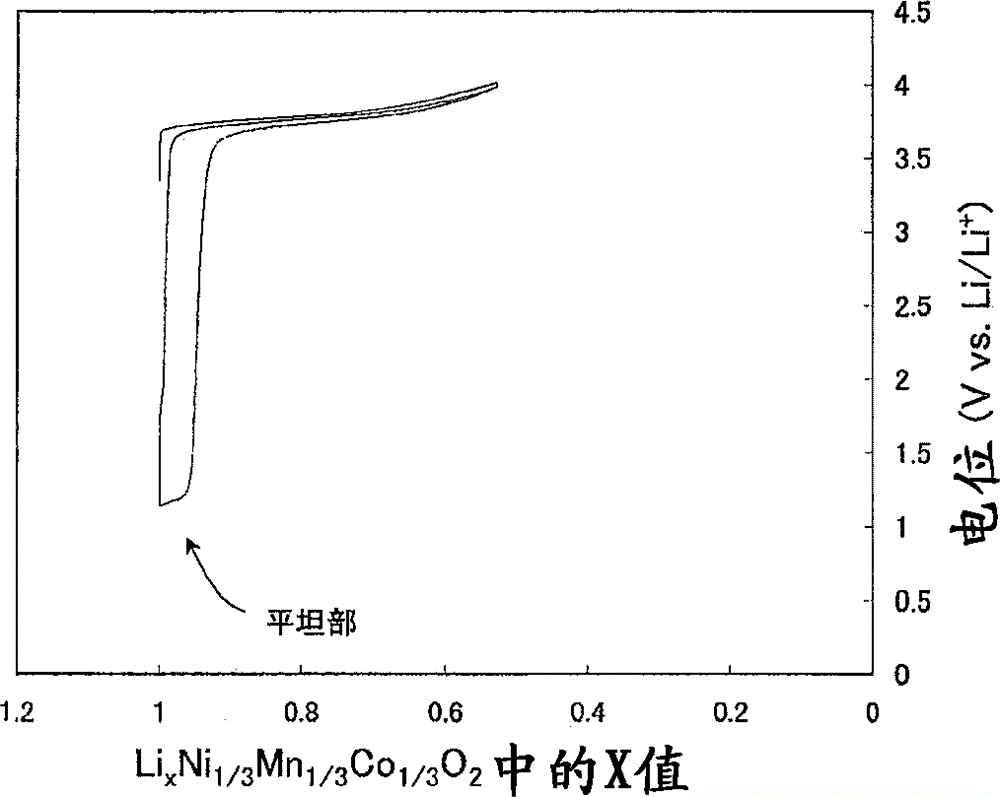

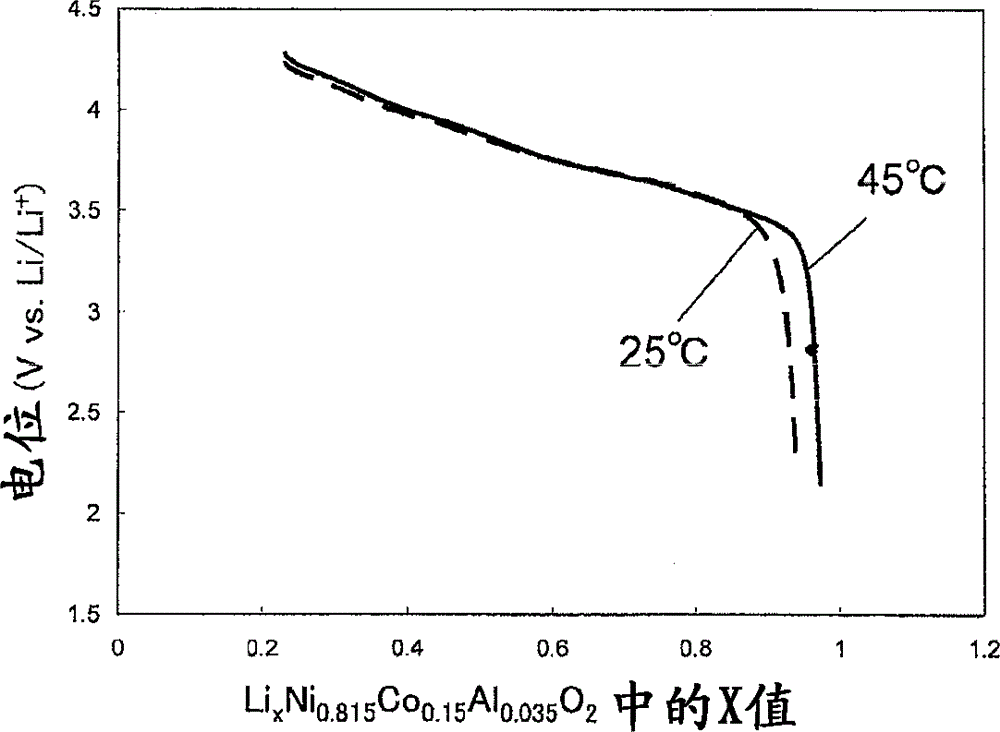

[0102] The inventors of the present invention studied the relationship between the discharge termination potential of the positive electrode active material and the charge-discharge reversibility during charge-discharge, produced a single cell for evaluation, and conducted an evaluation test. Hereinafter, the method and results will be described.

[0103] (1-1) Production of positive electrode active materials A, B, and C

[0104] As the positive electrode active material, three kinds of nickel-based lithium-containing composite oxides with different compositions are produced, that is, the composition is based on LiNi 0.815 co 0.15 Al 0.035 o 2 The positive electrode active material A represented by LiNi 0.76 co 0.14 Al 0.10 o 2 The positive active material B represented by , and the composition is represented by LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 Represented positive active material C.

[0105] The preparation method of the positive electrode active material A will be des...

no. 2 Embodiment approach

[0182] Next, a second embodiment of the present invention will be described with reference to the drawings. This embodiment is a charging and discharging method using a wound lithium secondary battery.

[0183] First, the structure of the lithium secondary battery in this embodiment will be described.

[0184] Figure 5 It is a schematic cross-sectional view of an example of the lithium secondary battery in this embodiment.

[0185] The lithium secondary battery includes a battery case 1 , an electrode group 4 housed in the battery case 1 , and insulating rings 8 arranged above and below the electrode group 4 . There is an opening above the battery case 1 , and the opening is sealed by a sealing plate 2 .

[0186] The electrode group 4 has a structure in which the positive electrode 5 and the negative electrode 6 are spirally wound multiple times with the separator 7 interposed therebetween. A positive electrode lead 5 a made of, for example, aluminum is drawn out from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com