Breeding hen quantitative feeding device

A chicken quantitative and feeder technology, which is applied in application, poultry industry, animal husbandry, etc., can solve the problems of uneven blanking, easy to be stuck, uneven feeding of breeders, etc., to achieve accurate quantitative blanking, Accurate measurement and positioning, good breeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

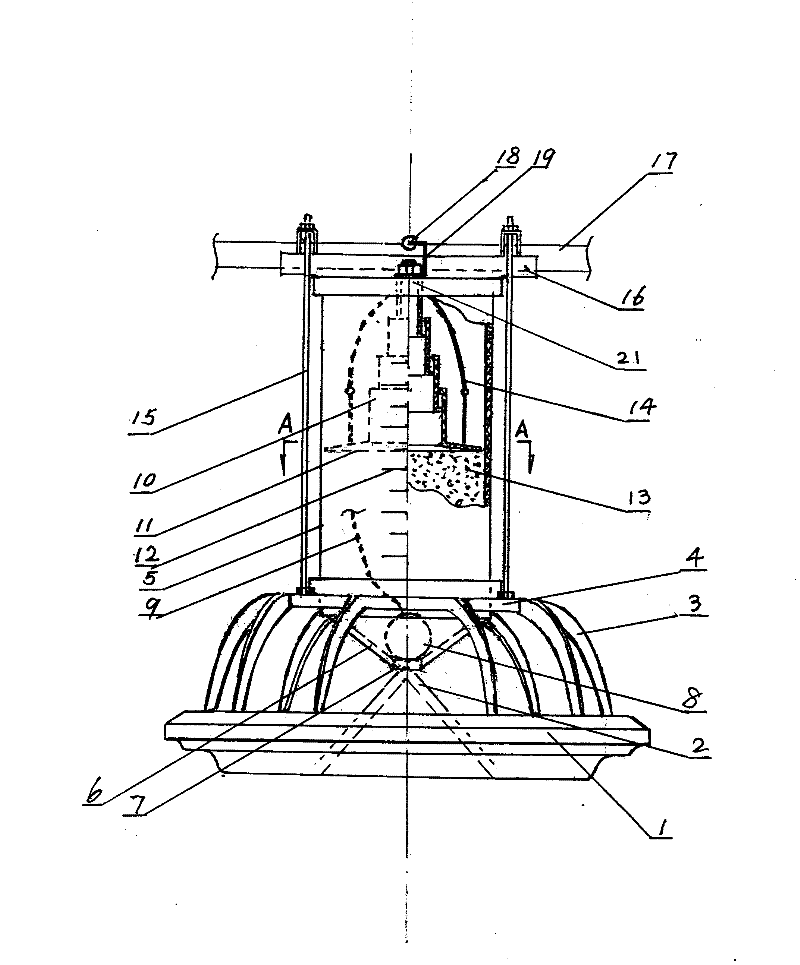

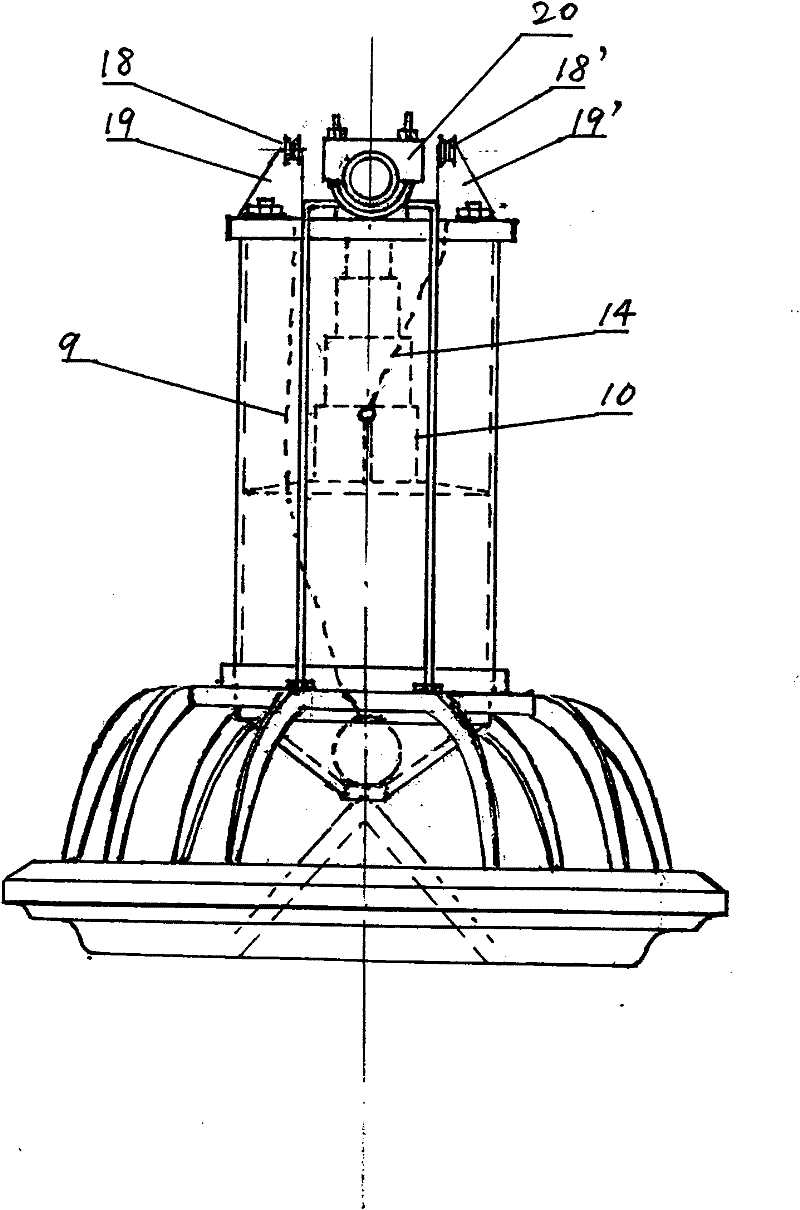

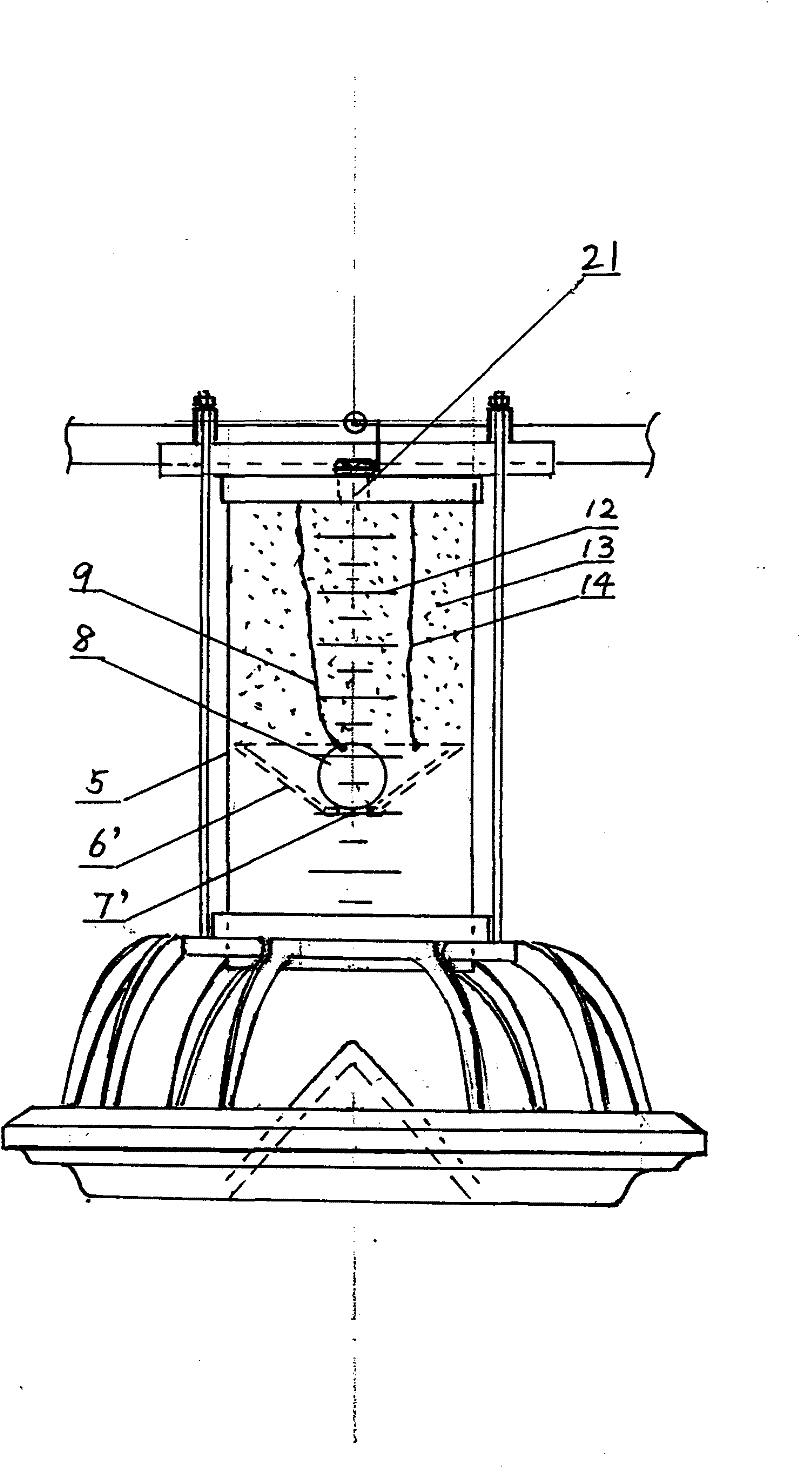

[0012] The above manual is attached figure 1 and 2 A specific embodiment of the present invention is given, and the structure of the present invention is further described in conjunction with it.

[0013] The invention comprises a bottom material tray 1, a grid 3 on it, a material bucket 5 mounted on the top ring 4 of the grid, and a material falling metering device in the material bucket 5. The blanking metering device in the barrel includes a sleeve-type retractable blanking tube 10, the upper opening of the blanking tube is connected to the blanking through hole 21 on the top of the barrel, the bottom of the blanking tube has a metering skirt 11, and the metering skirt is The periphery is matched with the inner wall of the material tank, and there is a gap that allows the metering skirt to move up and down flexibly in the material tank; it also includes a blanking funnel 6 with a central blanking hole 7 fixed at the bottom of the material tank, and the central blanking of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com