Cigarette filter tip firming method

A curing method and tip technology, which is applied in the fields of tobacco, e-liquid filter elements, applications, etc., can solve the problems of insufficient hardness of the cigarette tip, unsatisfactory hardness of the cigarette tip, and short volatilization time of triacetin, so as to achieve simple installation , uniform volatilization and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

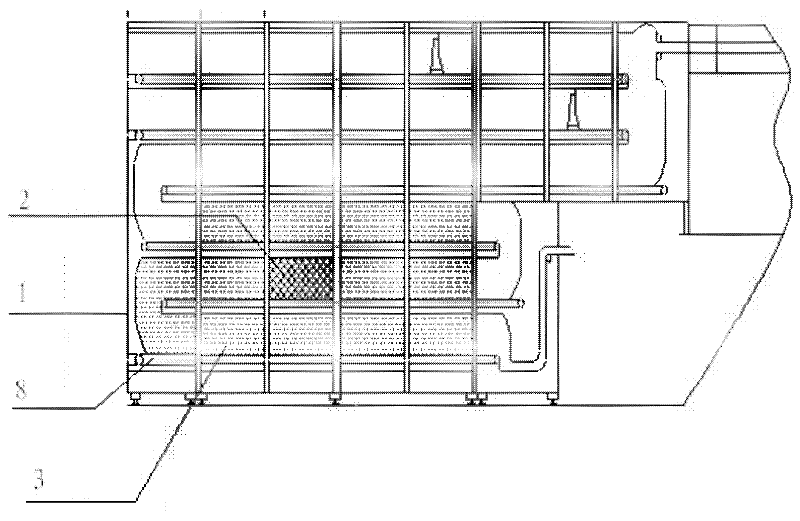

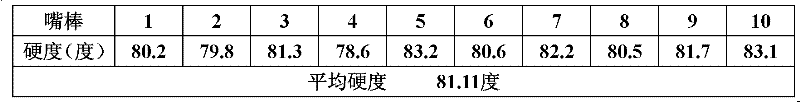

[0020] Adopt the molding equipment + storage cabinet + transmitter that are commonly used by domestic tobacco companies to produce cigarette tip sticks, such as figure 1 , figure 2 shown. Among them, the mouth stick 3 produced by the molding equipment enters the YF171A mouth stick storage cabinet 1 after passing through the HCF tray loading machine. The drying power of the storage cabinet 1 is set to 5KW, the drying temperature is set to 0°C-75°C, the length of the nozzle rod 3 is 100-120mm, and the diameter of the nozzle rod 3 is 5.4-9mm.

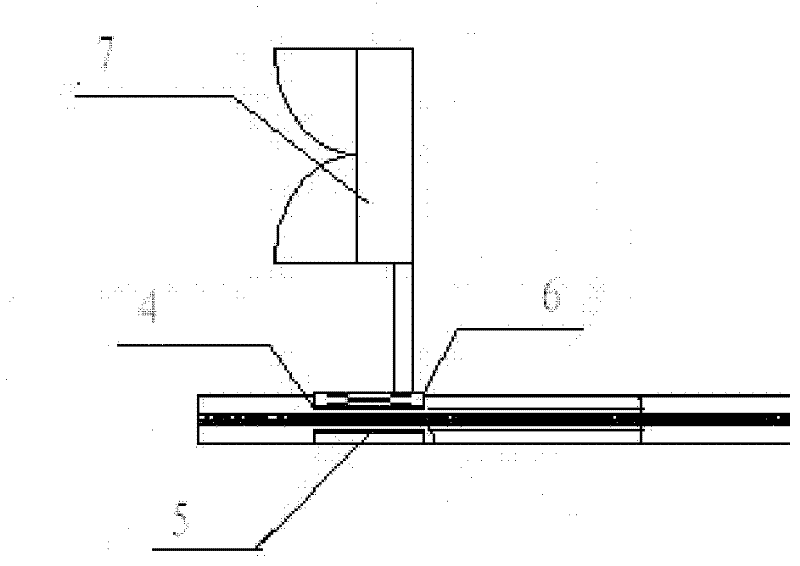

[0021] Renovate the cube 2 at the designated position (400×400×120) of the intermediate equipment YF171A mouth rod storage cabinet 1: replace the two opposite plexiglass doors at this position with the positive plate 4 and the negative plate of the high-frequency electric field 5 two electrode plates, at the positive plate 4, there is a radiation-proof metal cover 6 to seal the positive plate 5 to prevent electromagnetic radiation. The...

Embodiment 2

[0033] In this embodiment, the far-infrared heating method is used to heat the tip rod of the cigarette, and the data is obtained and compared with the data obtained by the electromagnetic radiation heating method of the present invention.

[0034] The principle of far-infrared heating: when the current passes through the heating wire of the infrared radiation heating tube, the heat will be transmitted to the material through the medium (air) and at the same time the infrared radiation heating tube will radiate a large amount of infrared rays of a certain wavelength. When the infrared rays are absorbed by the material, the material The internal molecules are activated to generate collision motion, which generates a large amount of heat energy, and the material is heated from the inside. In addition, the items heated by infrared radiation during dehydration and drying are all under the simultaneous action of the temperature gradient and humidity gradient of high inside and low o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com