Top-installed type automatic photogravure roller cleaning machine

A technology for automatic cleaning machines and gravure rolls, applied in the direction of dryers, cleaning methods and tools, cleaning methods using tools, etc., which can solve the problems of occupying printing machine production time, wasting water resources and cleaning fluid, and working efficiency needs to be improved, etc. problems, to achieve the effect of low production efficiency, high labor intensity and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

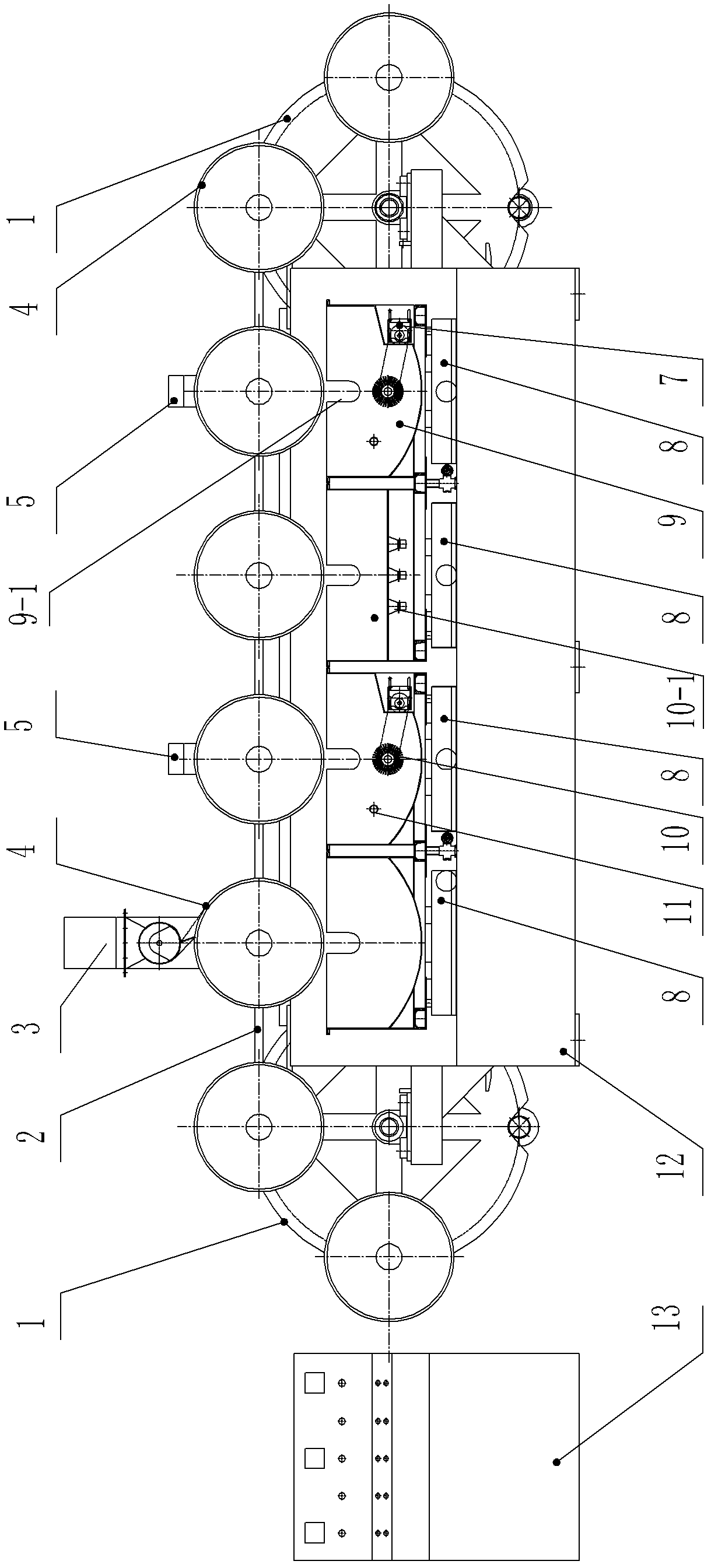

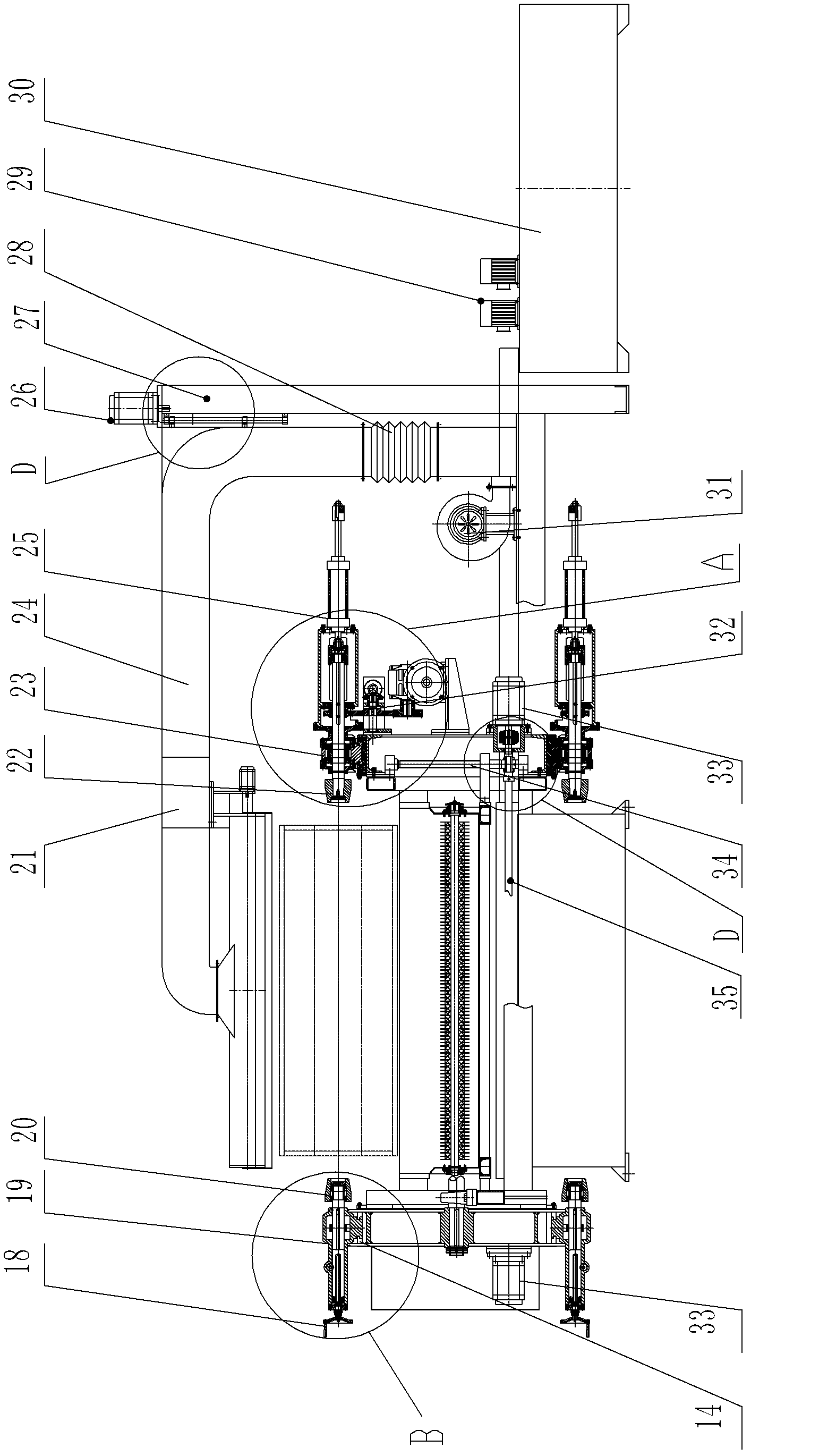

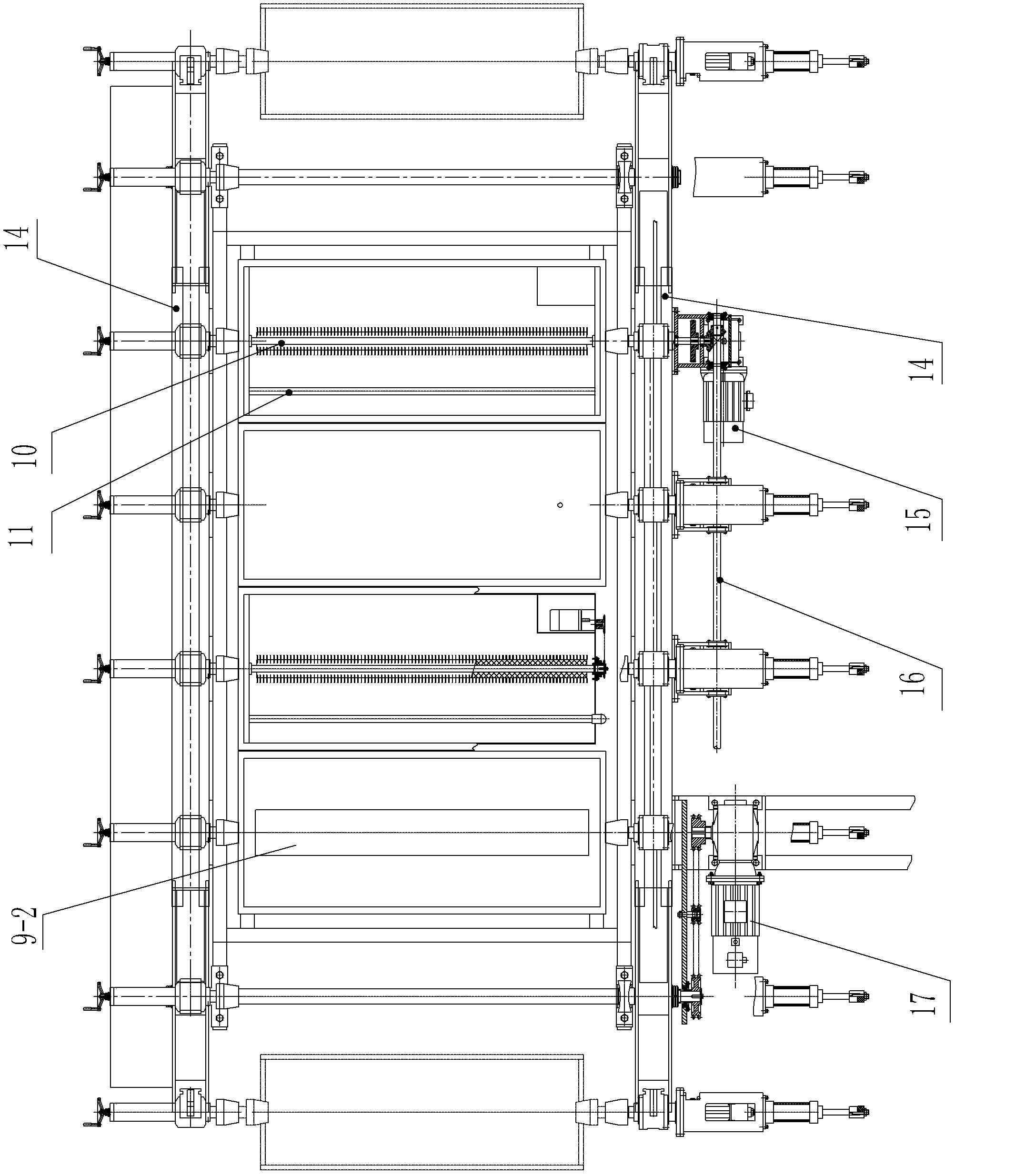

[0035] The technical solution of the present invention will be further described below through the accompanying drawings of the description.

[0036] As shown in the figure, the top-mounted gravure roll automatic cleaning machine includes a box-type frame 12 with a cavity, a gravure roll cleaning system installed in the cavity, and a matching gravure roll cleaning system. A water-saving circulation system, a gravure roller transmission system installed on the frame, and a host 13 controlling the gravure roller cleaning system, the gravure roller transmission system and the water-saving circulation system.

[0037] The opening of the box-type rack faces upwards (for directions refer to figure 1 ), the bottom of the cavity of the box-type frame is 30-60cm away from the ground (specifically determined according to the specifications of the gravure roller).

[0038] The plate roller conveying system includes two sprocket mechanisms arranged at the front and rear of the frame (dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com