Online detection system for solid-phase internal boundaries and solidification end positions of continuous casting blanks and method

A technology of solidification end and continuous casting billet, applied in the field of steelmaking and continuous casting, can solve the problems of time-consuming and laborious signal-to-noise ratio, inability to realize online detection of the solid phase inner boundary of the continuous casting billet and the position of the solidification end, and reduce heat radiation. , prolong the service life, improve the effect of signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

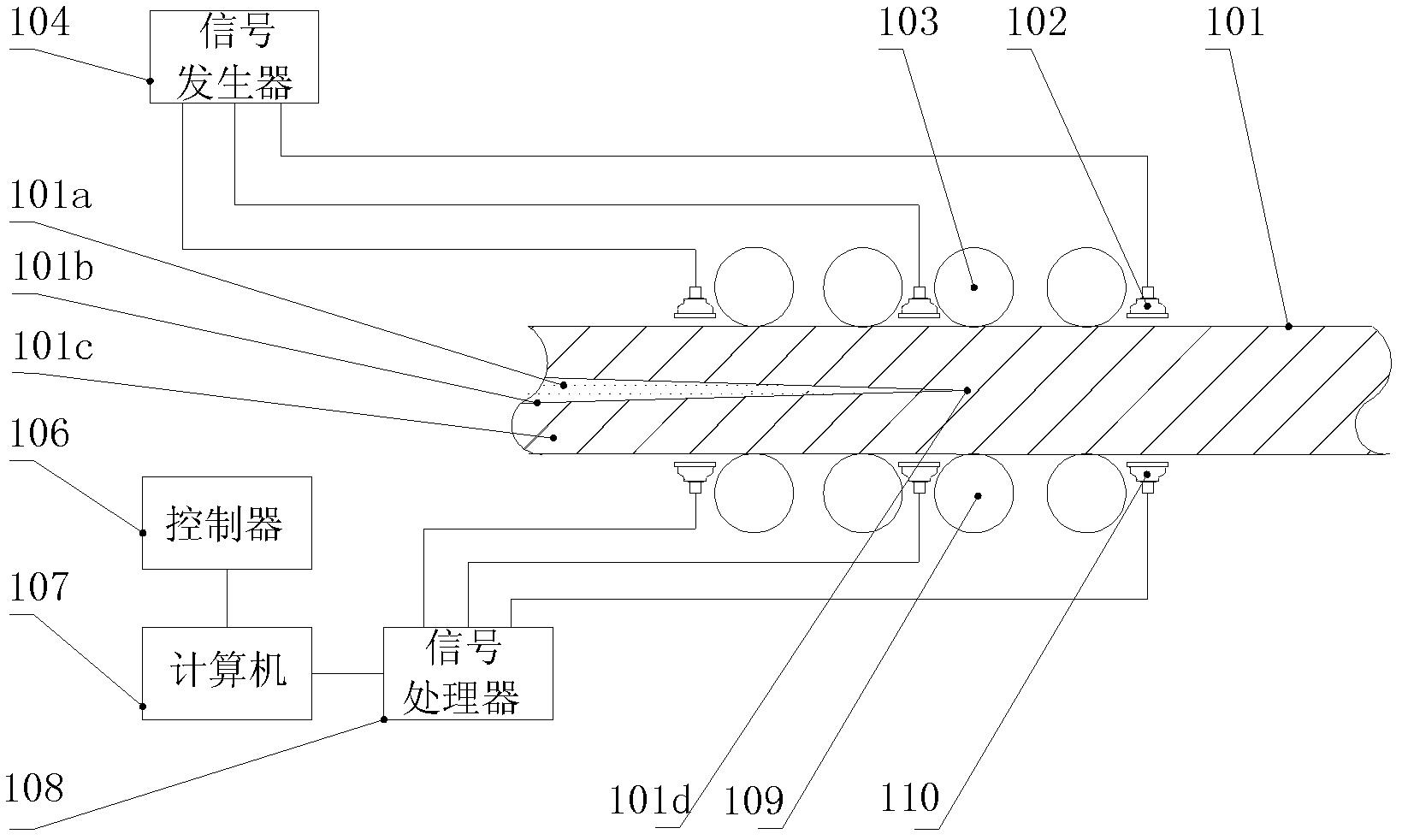

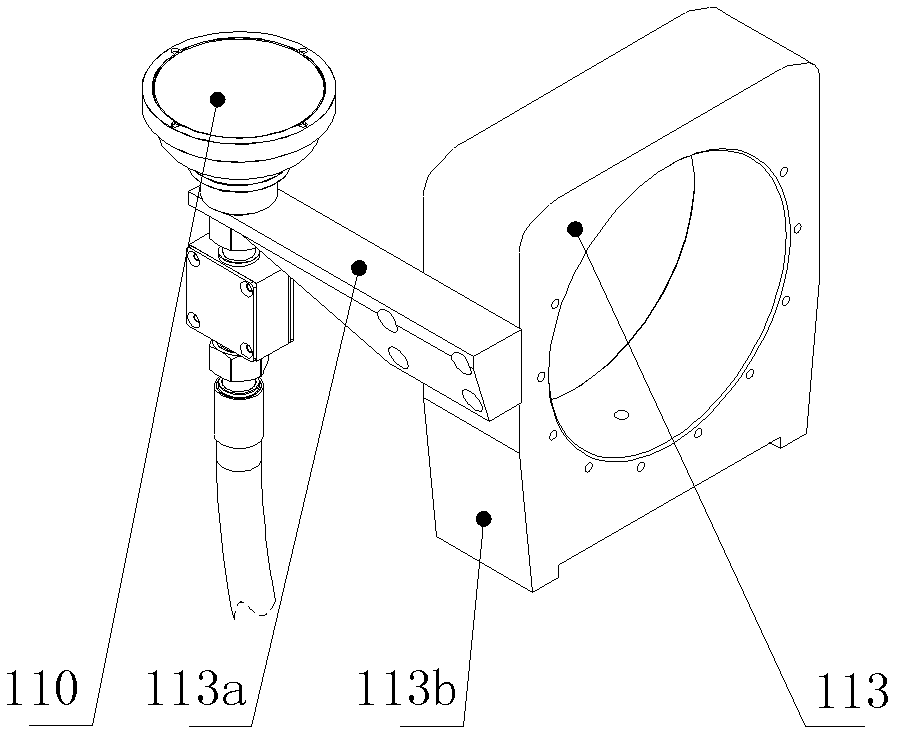

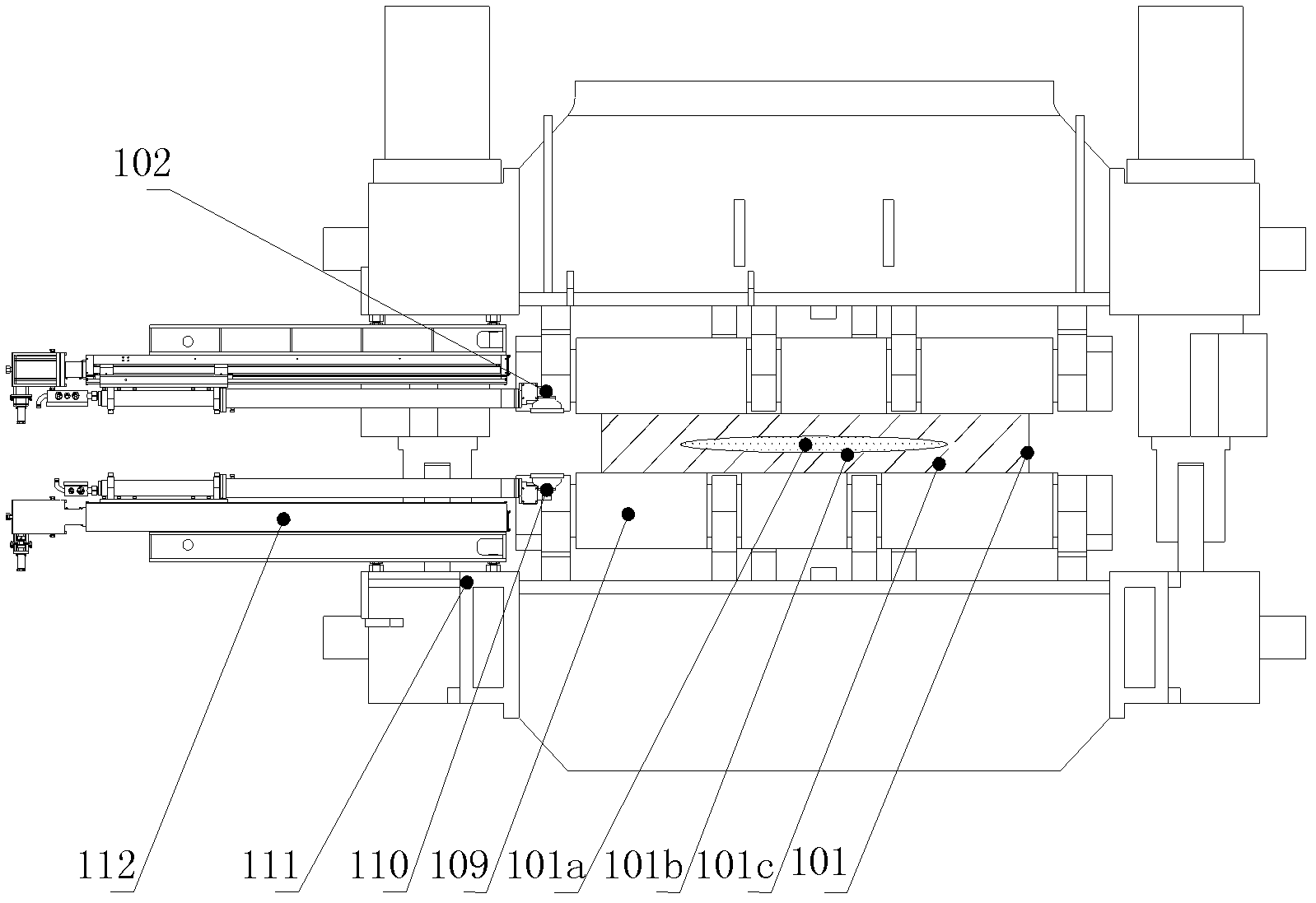

[0090] Figure 1 to Figure 4 Shown is a continuous casting slab solid phase inner boundary and solidification end detection system according to the first embodiment of the present invention. combined reference Figure 1 to Figure 4 , The detection system of the present invention includes: a signal generator 104 , an electromagnetic ultrasonic sensor, a signal processor 108 , a computer 107 and a controller 106 . The signal generator 104 outputs the generated excitation signal to the sensor 102 for emitting electromagnetic ultrasonic waves, and the sensor 110 for receiving electromagnetic ultrasonic waves receives the electromagnetic ultrasonic signals emitted by the sensor 102 for emitting electromagnetic ultrasonic waves and passing through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com