One-dimensional Sb203 micro-nanometer powder and composite-morphological Sb203 micro-nanometer powder prepared in one-step method

A micro-nano, sb2o3 technology, applied in nanotechnology, antimony compounds, chemical instruments and methods, etc., can solve the problems of easy hard agglomeration of products, affecting the quantum effect of nanoparticles, surface effect, etc., and achieve hard agglomeration and low cost. , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] At 60°C, put 5 mL of 0.5 mol / L SbCl 3 The ethanol solution was added dropwise to 45 mL of 3% (wt %) ammonia solution, stirred by magnetic force for 0.2 h, and then the hydrolyzed Sb 2 o 3 The suspension was filtered, washed, and oven-dried at 60 °C to obtain Sb 2 o 3 powder sample.

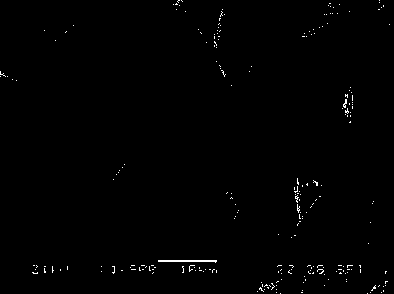

[0026] A small amount of prepared Sb 2 o 3 The powder sample is directly adhered to the copper platform with conductive adhesive, and after spraying gold, it is observed under the scanning electron microscope, the results are as follows figure 1 shown. The particles that can be seen from the figure are ribbon-shaped, with a length of 10-20 μm, and the thickness of a single nanobelt is about 100 nm.

Embodiment 2

[0028] At 40°C, put 20 mL of 0.1 mol / L SbCl 3 The ethanol solution was dropped into 50 mL of 5% (wt %) ammonia solution, stirred by magnetic force for 0.5 h, and then the hydrolyzed Sb 2 o 3 The suspension was filtered, washed, and oven-dried at 60 °C to obtain Sb 2 o 3 powder sample.

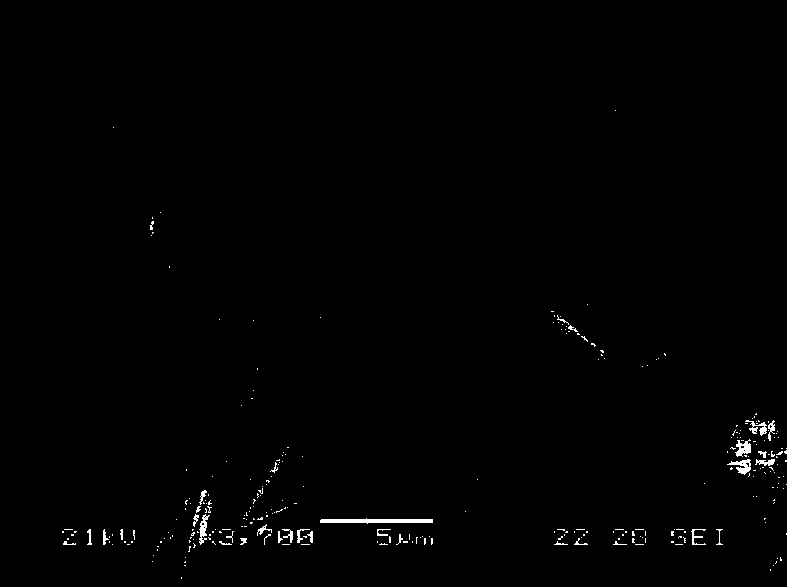

[0029] A small amount of prepared Sb 2 o 3 The powder sample is directly adhered to the copper platform with conductive adhesive, and after spraying gold, it is observed under the scanning electron microscope, the results are as follows figure 2 shown. The particles that can be seen from the figure are belt-shaped, with a length of about 20 μm. The thickness of a single nanoribbon is about 100 nm, and the length of one side of the belt can reach 10 μm.

Embodiment 3

[0031] At 60°C, put 5 mL of 0.5 mol / L SbCl 3 The ethanol solution was poured into 45 mL of 6% (wt %) ammonia solution, stirred electrically for 0.1 h, and then the hydrolyzed Sb 2 o 3 The suspension was filtered, washed, and oven-dried at 60 °C to obtain Sb 2 o 3 powder sample.

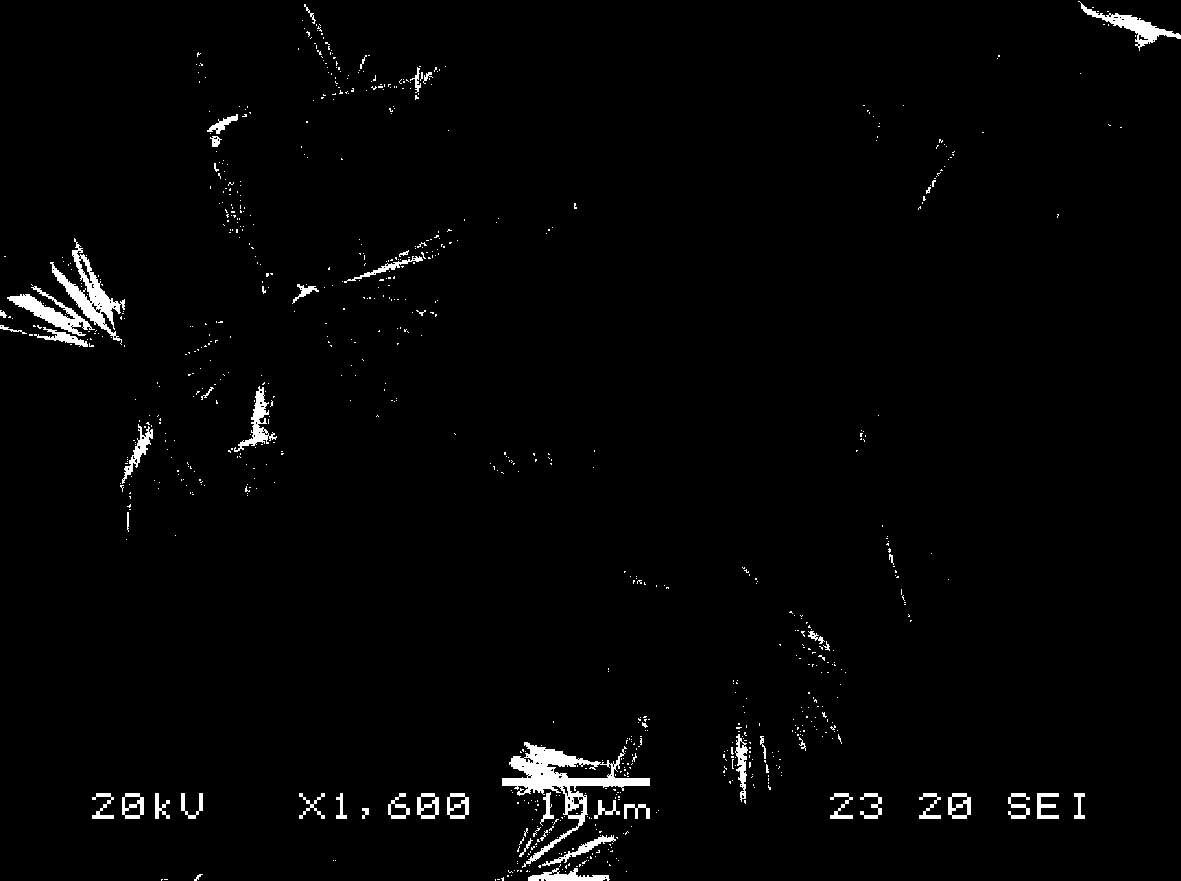

[0032] A small amount of prepared Sb 2 o 3 The powder sample is directly adhered to the copper platform with conductive adhesive, and after spraying gold, it is observed under the scanning electron microscope, the results are as follows image 3 shown. The particles that can be seen from the figure are bowknot-shaped, with a length of about 20 μm. The thickness of the nanoribbons that make up the bowtie is about 100 nm, and the length of one side of the bowtie can reach 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com