Preparation method of ferroferric oxide (Fe3O4) nanobelt in network structure

A technology of ferric oxide and network structure, which is applied in the direction of iron oxide/iron hydroxide, nanotechnology, oxides of ferrous iron, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

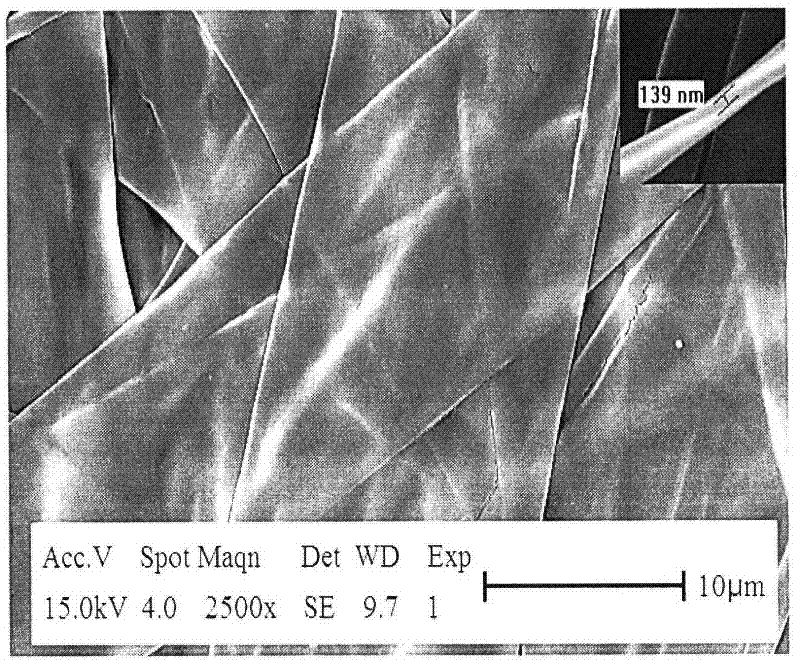

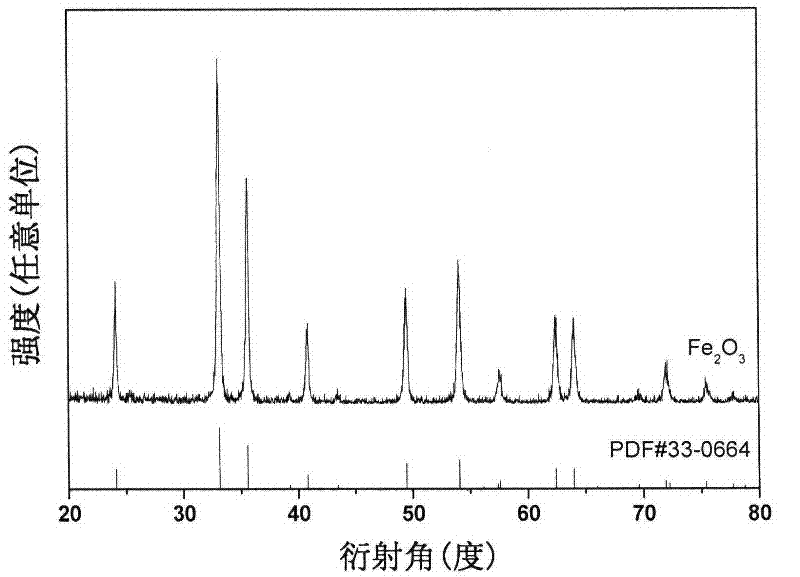

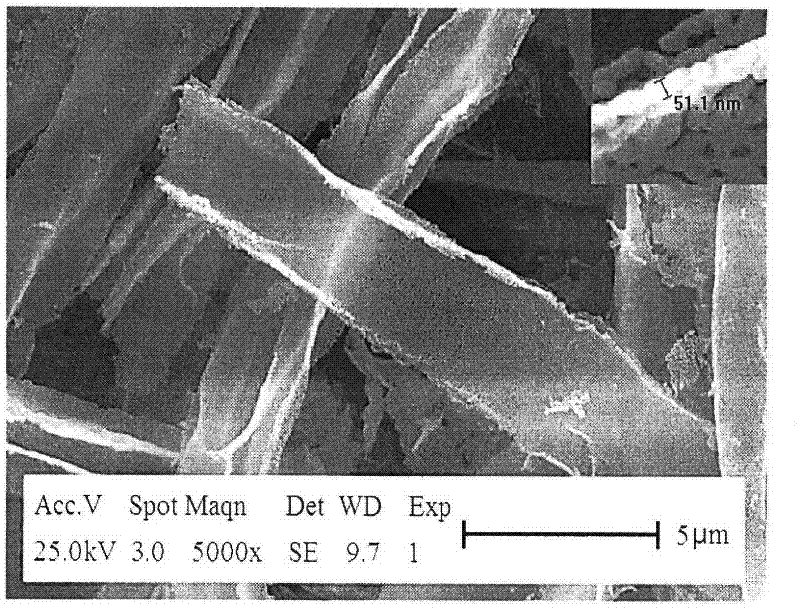

[0022] Example: 1g Fe(NO 3 ) 3 9H 2 O was added in 10g DMF and magnetically stirred and mixed evenly, then added 3.6g PVP, continued to stir for 12h to obtain a spinning solution, added the prepared spinning solution into the liquid storage tube of the spinning device, inserted a carbon rod as an anode, Use barbed wire as the cathode, the inner diameter of the nozzle is 0.5mm, adopt the vertical spraying method, the nozzle is perpendicular to the horizontal plane, apply a DC voltage of 8kV, the curing distance is 14cm, the room temperature is 18-25°C, and the relative humidity is 40%-70%. Electrospinning is carried out to obtain PVP / Fe(NO 3 ) 3 Composite nanoribbons with a width of about 13.35 μm and a thickness of about 139 nm, see figure 1 shown; the PVP / Fe (NO 3 ) 3 The composite nanobelts were heat-treated in a programmable temperature-controlled furnace, and the temperature was raised to 650°C at a rate of 1°C / min and kept for 4 hours, and then naturally cooled to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com