Modified EVA (ethyl?vinyl acetate) foaming body and preparation method and application of the same

A foam and modification technology, applied in the field of modified EVA foam and its preparation and application, can solve the problems of shrinkage and compression deformation of injection EVA products, and achieve good durability, good durability and excellent durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

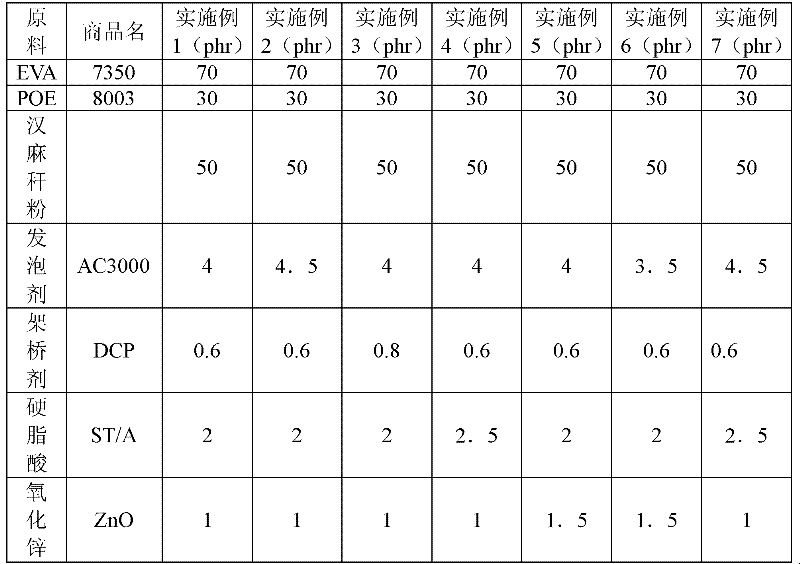

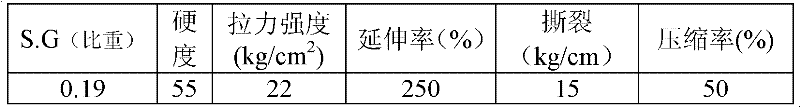

[0021] Embodiment 1, prepare modified EVA foam

[0022] The trade name of 70 parts by weight is EVA7350, the number average molecular weight is 800-2000 ethylene ethyl acetate copolymer (the mass percent composition of ethyl acetate (VA) is 18%), the trade name of 30 parts by weight is POE8003 , Polyolefin elastomer with a number average molecular weight of 600-2000 and 50 parts by weight of hemp stalk core powder with a particle size of 500 mesh are put into an internal mixer for mixing. During the mixing process, the temperature of the mixer does not exceed 70 degrees , the mixing temperature is 80-100°C, and the mixing time is 0.2 hours;

[0023] Simultaneously with the whipping agent azodicarbonamide of AC3000 by the trade name of 4 parts by weight, the bridging agent dicumyl peroxide (DCP) of 0.6 part by weight, the activator stearic acid of 2 parts by weight and 1 part by weight Put the zinc oxide into another internal mixer for mixing. During the mixing process, the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com