A method for repairing the leakage of concentration pool and water pool

A repair method and technology of a concentration tank, which are applied in water conservancy projects, marine engineering, construction and other directions, can solve problems such as the uncompact bonding of upper and lower concrete, concrete leakage, and leakage control, so as to achieve an economical and practical method, solve the problem of water leakage, and achieve effective results obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

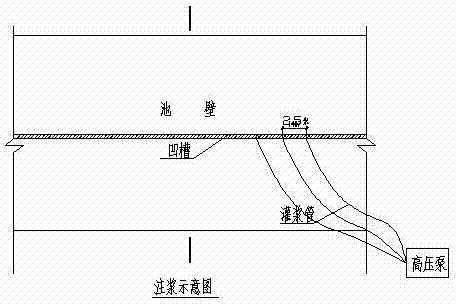

[0029] A method for repairing the leakage of a concentration pool and a pool, comprising the following steps,

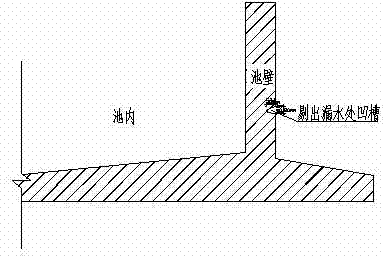

[0030] - Dig a groove at the seepage, rinse the base surface of the groove with water,

[0031] - fix the grouting pipe in sections in the chiseled groove,

[0032] -Fill the groove with accelerator in 2 times and compact it firmly,

[0033] - Inject polyurethane into the grouting pipe with a grouting pump,

[0034] - Cut off the grouting pipe after the accelerator solidifies,

[0035] - paste foam plastic strips on top of the accelerator,

[0036] - Then fill polysulfide rubber caulking paste from both sides of the groove seam to the middle,

[0037] - apply waterproof mortar,

[0038] - Apply XYPEX Concentrate.

[0039] The groove is 20mm wide and 40mm deep.

[0040] The section is 2.5m, that is, one grouting pipe is installed for every 2.5m groove on average.

[0041] The quick-setting agent is Jintangshuibulei, XYPEX repair and plugging agent, water-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com