Generator rotor unbalance magnetic tension testing bench supported by sliding bearings

A technology of generator rotor and sliding bearing, applied in vibration testing, testing of machine/structural components, measuring devices, etc., can solve the problem of increased system vibration, unbalanced electromagnetic force of radial and tangential components, reduced power generation efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

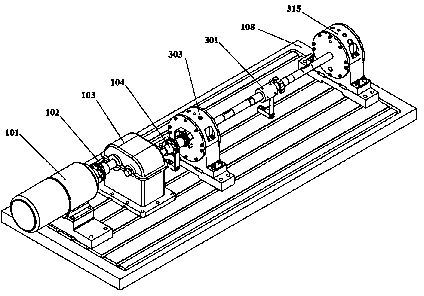

[0047] Such as Figure 1 to Figure 3 , an unbalanced magnetic tension test bench for a generator rotor supported by a sliding bearing, comprising a variable pole logarithm generator rotor spindle system, a basic frame of the test bench and a generator stator output load adjustment system.

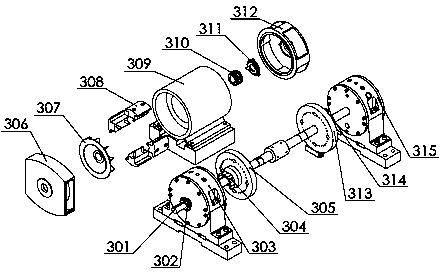

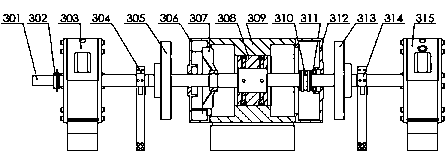

[0048] Among them, the variable magnetic pole logarithm generator rotor spindle system further includes:

[0049] Generator rotor 301, tachometer wheel 302, front sliding bearing support subsystem 303, first sensor bracket 304, first balance weight wheel 305, stator front end cover 306, cooling fan 307, generator rotor iron core and excitation coil 308 , Generator stator 309, slip ring 310, carbon brush bracket 311, carbon brush, stator rear end cover 312, second balance weight wheel 313, second sensor bracket 314, rear sliding bearing support subsystem 315.

[0050] The tachometer wheel 302, the generator rotor iron core, the excitation coil 308, and the slip ring 310 are all installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com