Indirect test evaluating method for hollowness of bombax cotton fiber

A technology of kapok fiber and evaluation method, which is applied in the direction of applying stable tension/pressure to test the strength of materials and the preparation of test samples, which can solve the problems of long time consumption, complicated operation of the test process, and inability to guarantee the secondary deformation of kapok fiber, etc. , to achieve the effect of avoiding secondary deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

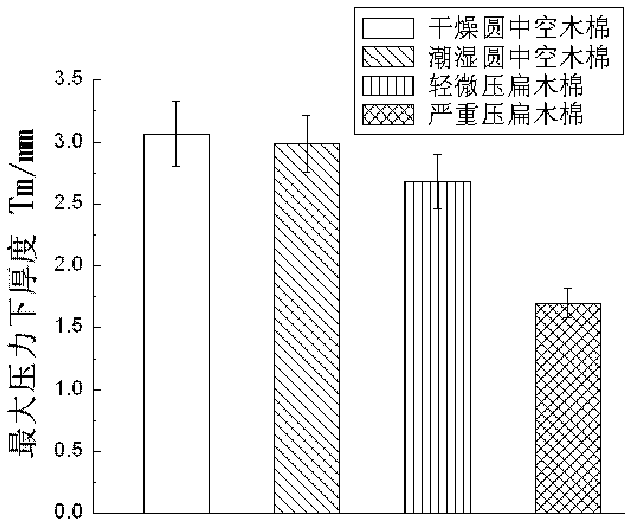

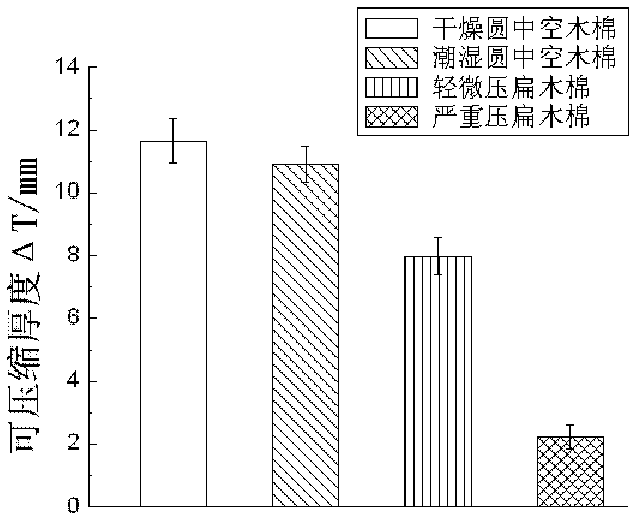

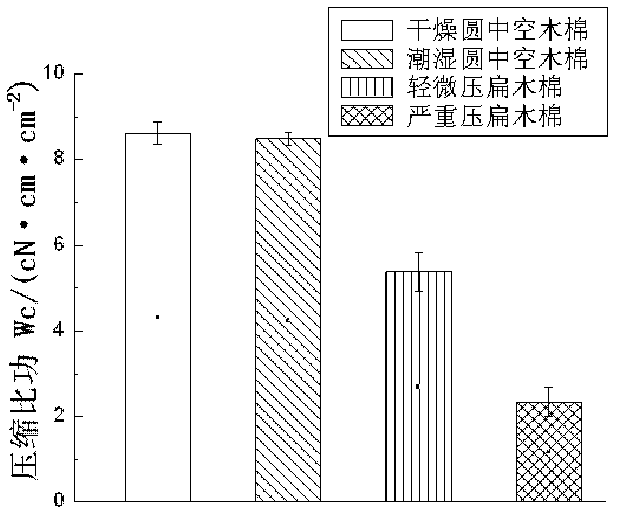

[0029] Embodiment 1 (dry kapok raw cotton and its fiber hollowness test evaluation after wet pressure treatment)

[0030] (1) Sample preparation: After dry kapok (humidity adjustment for 24 hours in an environment with a relative humidity of 15%) and humid pressurization treatment (humidity adjustment in an environment with a relative humidity of 99% for 24 hours, and then a pressure of 100KPa for 15 seconds) 10 samples of kapok fiber bundles were made in each of the fibers, and each sample was combed in parallel to determine the weight of 100mg, and placed in a rectangular container of 3cm×3cm;

[0031] (2) Test method: use a compression performance tester to test in a constant temperature and humidity room, and the pressure head is 5cm in area 2 The circular indenter, with 0.2mm·s -1 Press vertically to the sample at a constant speed, return at the original speed after the test pressure reaches 50Pa, and measure the relationship between the pressure per unit area of the f...

Embodiment 2

[0036] Embodiment 2 (the hollowness test evaluation of dry kapok and moist micro-pressed kapok fiber)

[0037] (1) Sample making: each make 10 kapok fibers from the fibers of dry kapok (same as embodiment 1) and wet kapok (humidity adjustment in 99% relative humidity environment for 24 hours, then continue to act for 15 seconds with a pressure of 10KPa) Beam sample, preparation method is with embodiment 1;

[0038] (2) Test method: use a compression performance tester to test in a constant temperature and humidity room, and the pressure head is 2cm in area 2 The circular indenter, at 0.5mm·s -1 Press vertically to the sample at a constant speed, return at the original speed after the test pressure reaches 50Pa, and measure the relationship between the pressure per unit area of the fabric and the thickness of the compressed sample;

[0039] (3) Index calculation and result analysis: See the first two rows of Table 2 for the index calculation results, and the last row of Tab...

Embodiment 3

[0045] Embodiment 3 (hollowness test evaluation of kapok blended fabric)

[0046] (1) Sample production: use 21s cotton air-jet yarn as the warp yarn, and the weft yarns are 20s of 80% cotton / 20% kapok yarn and 100% cotton yarn respectively, weave plain weave fabric with warp and weft density (246×218) per 10cm, And the finishing process after the front sanding. Cut 3 pieces of flat fabric samples with a size of 20cm×20cm at different positions;

[0047] (2) Test method: the same as in Example 1, but the constant speed at which the indenter of the compression performance tester presses vertically to the sample should be set at 0.05 mm s -1 ;

[0048] (3) Index calculation and result analysis: the index calculation results are shown in the first two rows of Table 3, and the test results of the significance of the performance difference between kapok blended fabric and cotton fabric are shown in the last row of Table 3. There are significant differences in the four major indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com