Quantitative analysis method for residual life of T91 steel pipes

A quantitative analysis, T91 technology, used in particle size analysis, particle and sedimentation analysis, measuring devices, etc., can solve problems such as large errors and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

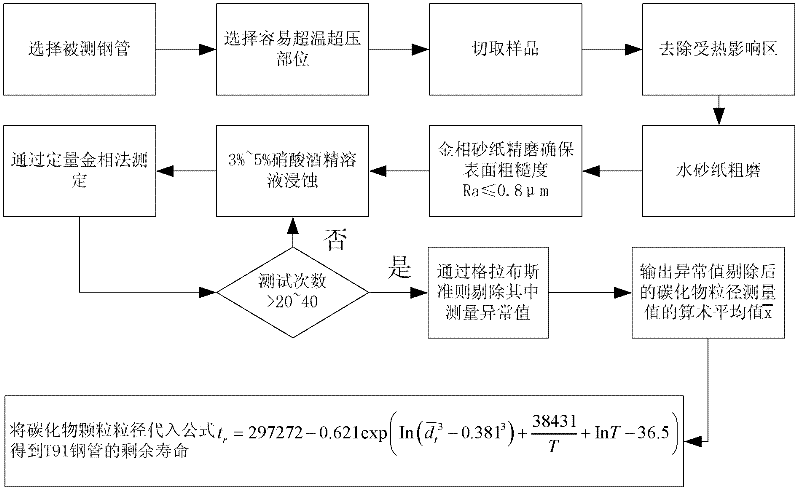

Method used

Image

Examples

Embodiment 1

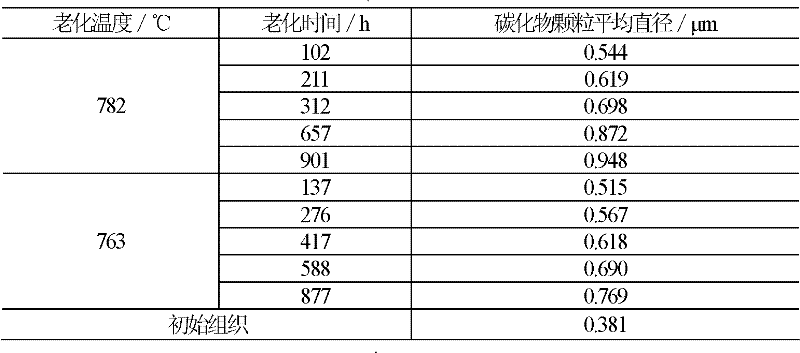

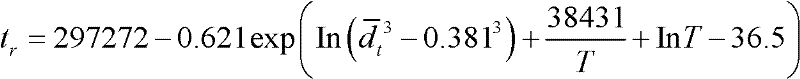

[0064] In a thermal power plant in Shaoxing, a superheater tube is selected as the tested part. The material of the superheater tube is T91 steel, and the working temperature is 600 °C. From the side elbow of the superheater tube close to the boiler, 20 samples were cut with a Bosch GWS7-125 angle grinder, and water was sprayed during the cutting process to reduce the cutting temperature. Then use the XQ-1 metallographic sample mounting machine to inlay the cut samples, and then replace them with No. 180, No. 320 and No. 400 in the MP-1 single-disk two-speed metallographic sample grinding and polishing machine. , No. 500, and No. 600 water sandpaper for rough grinding in turn. Then change to No. 01, No. 02, and No. 03 metallographic sandpaper for fine grinding to ensure that the surface roughness Ra≤0.8μm. The grinding surface should be cleaned before each replacement of different types of sandpaper. During the whole mechanical grinding process, water should be sprayed at th...

Embodiment 2

[0068]In a thermal power plant in Ningbo, a reheater tube is selected as the tested part. The material of the reheater tube is T91 steel, and the working temperature is 620°C. From the elbow of the reheater tube near the flue gas side, 20 samples were cut with a Bosch GWS 720 angle grinder, and water was sprayed during the cutting process to reduce the cutting temperature. Then use the XQ-2B metallographic sample mounting machine to inlay the cut samples, and then replace them with No. 180, No. 320, No. 400, and No. 500 on the MoPao160 single-disk two-speed metallographic sample grinding and polishing machine No., No. 600 water sandpaper for rough grinding in turn. Then change to No. 01, No. 02, and No. 03 metallographic sandpaper for fine grinding to ensure that the surface roughness Ra≤0.8μm. The grinding surface should be cleaned before each replacement of different types of sandpaper. Moreover, water should be sprayed at the same time during the whole mechanical grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com