SF6 (Sulfur Hexafluoride) micro-water content transducer calibration device

A micro-moisture content calibration device technology, applied in the direction of material moisture content, etc., can solve the problems of low accuracy, slow calibration speed, and complicated operation of the calibration device, and achieve uniform micro-moisture content, high accuracy, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

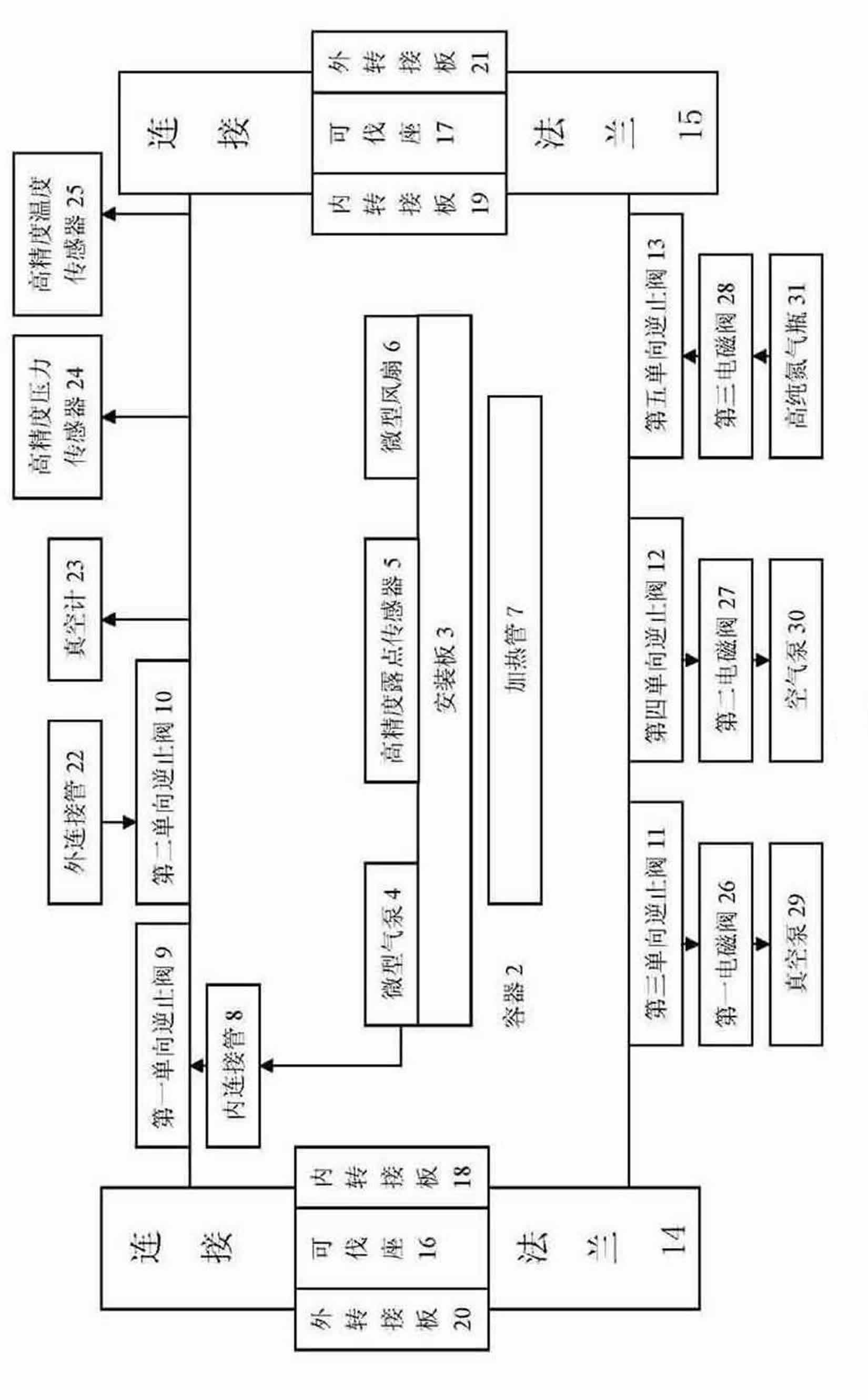

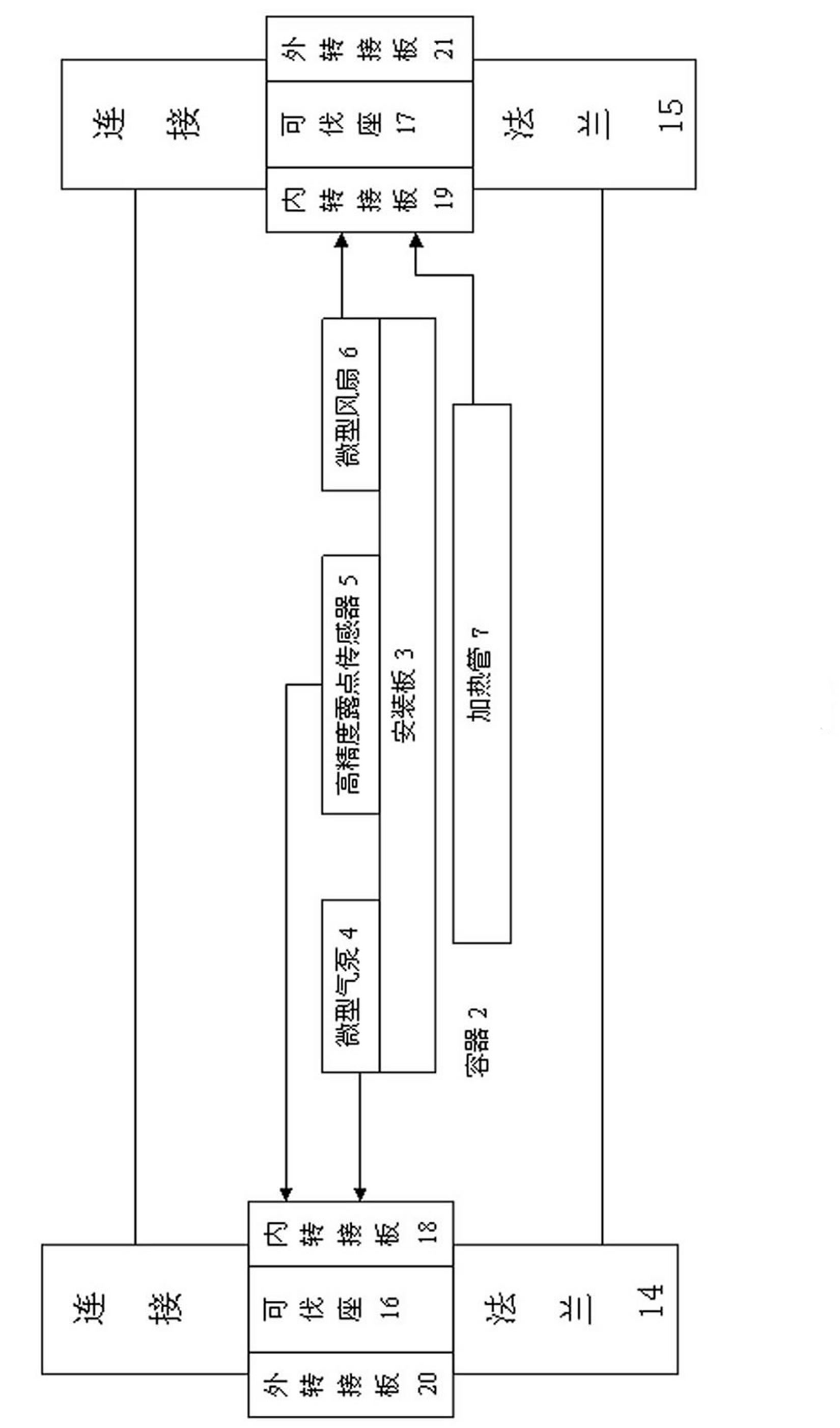

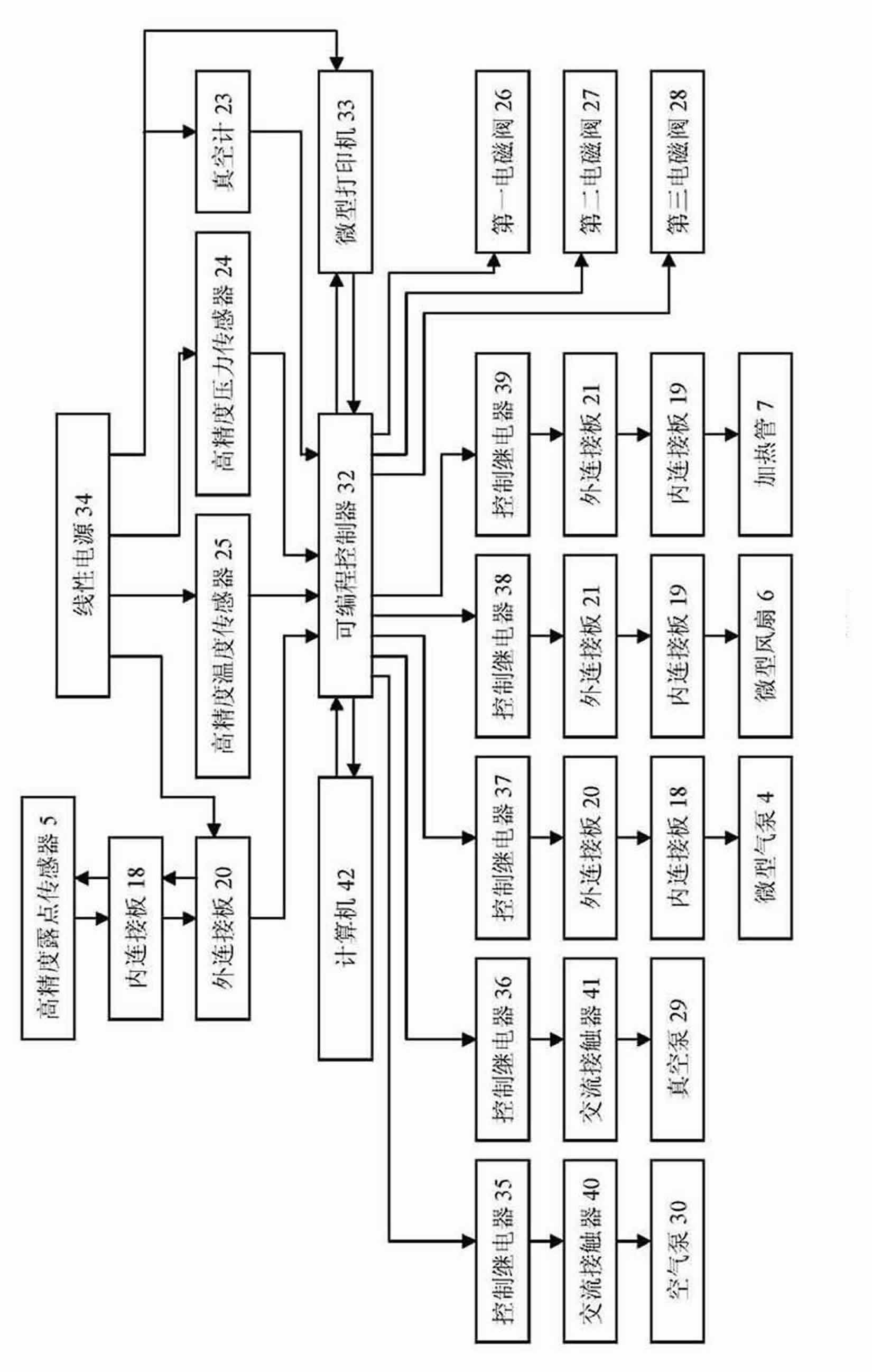

[0033] As shown, SF 6 Micro water content transmitter calibration device, it includes SF 6 Moisture content transmitter, container 2, micro air pump 4, high-precision dew point sensor 5, inner connecting pipe 8, outer connecting pipe 22, first one-way check valve 9, second one-way check valve 10, third One-way check valve 11, fifth one-way check valve 13, high-precision pressure transmitter 24, high-precision temperature transmitter 25, first solenoid valve 26, third solenoid valve 28, vacuum pump 29, high-purity nitrogen Bottle 31, programmable controller 32 and computer 42.

[0034] The micro air pump 4 and the high-precision dew point sensor 5 are placed in the container 2; the detection ports of the high-precision pressure transmitter 24 and the high-precision temperature transmitter 25 communicate with the inner cavity of the container 2 respectively.

[0035] The second one-way check valve 10 , the third one-way check valve 11 and the fifth one-way check ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com