Funtionalized carbon nanotube modified electrode and its preparation method and uses

A technology of carbon nanotubes and modified electrodes, which is applied in the direction of material electrochemical variables, etc., to achieve the effect of increasing specific surface area, good electrochemical response and separation effect, and fast and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

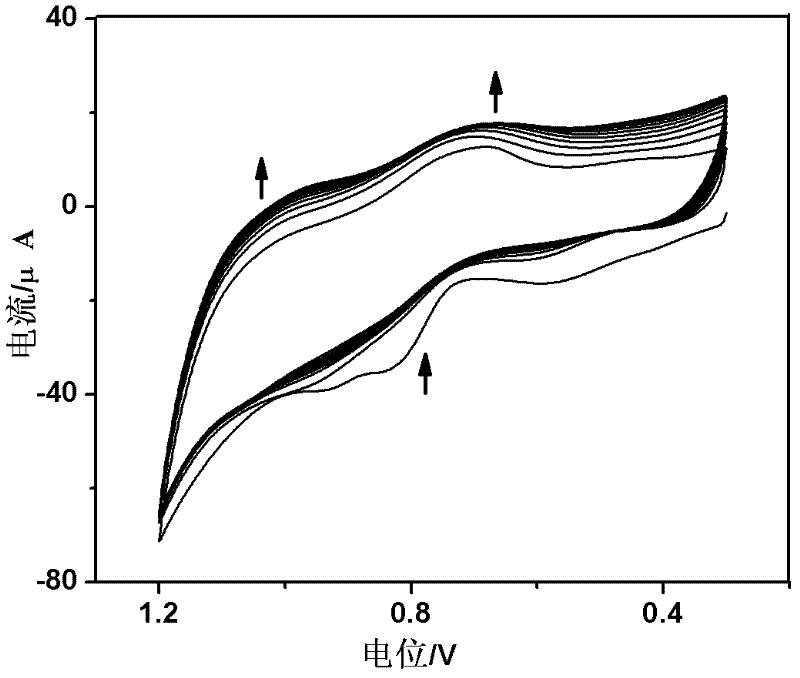

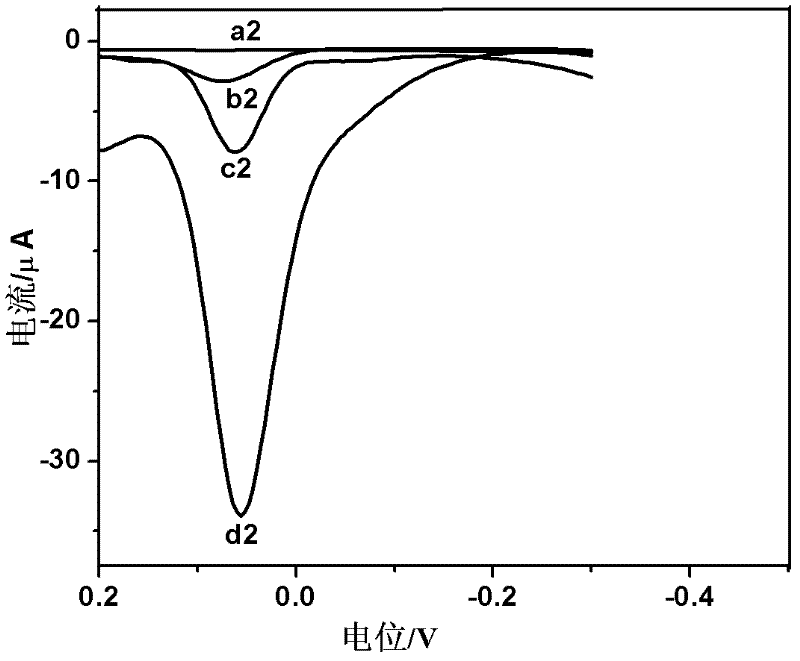

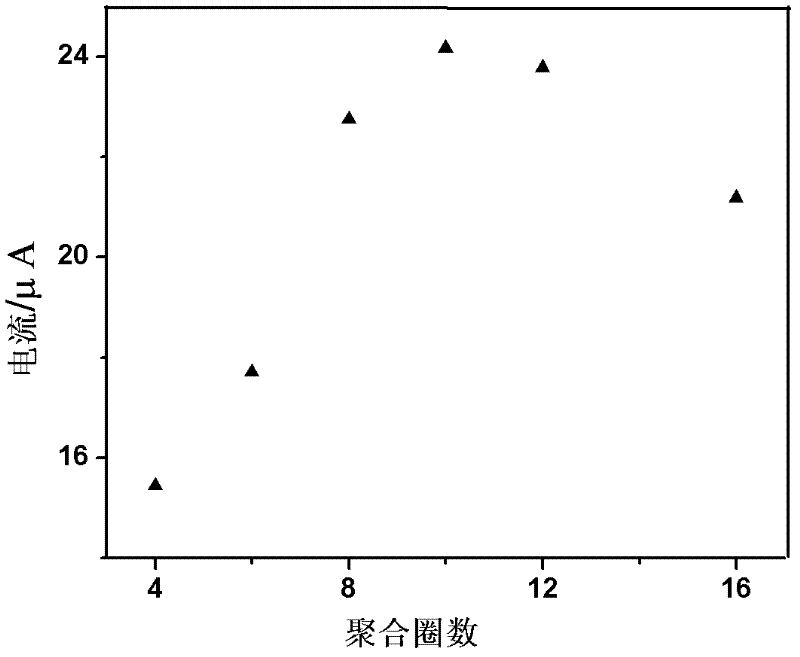

[0048] 1. Preparation of functionalized carbon nanotube modified electrode:

[0049] 1. Preparation of carbon nanotube modified electrode:

[0050] (1) Place the multi-walled carbon nanotubes in a mixed acid of concentrated sulfuric acid and concentrated nitric acid (volume ratio 3:1) for oxidation treatment to introduce oxygen-containing groups. Disperse the oxidized multi-walled carbon nanotubes in 2mL N,N-dimethylformamide (DMF) ultrasonic treatment for 30 minutes to form a 1 mg / mL black carbon nanotube suspension;

[0051] (2) The glassy carbon electrode was polished into a mirror surface with 0.3μm and 0.05μm aluminum oxide suspensions, and then washed with 95% ethanol and double distilled water in order to obtain a bare glassy carbon electrode;

[0052] (3) After drying the above-mentioned bare glassy carbon electrode with nitrogen with a purity of 99.999%, 5μL of carbon nanotube suspension was drip-coated onto the surface of the bare glassy carbon electrode, and then dried unde...

Embodiment 2

[0093] Preparation of functionalized carbon nanotube modified electrode:

[0094] 1. Preparation of carbon nanotube modified electrode:

[0095] (1) Place the multi-walled carbon nanotubes in a mixed acid of concentrated sulfuric acid and concentrated nitric acid (volume ratio 3:1) for oxidation treatment to introduce oxygen-containing groups. Disperse the oxidized multi-walled carbon nanotubes in 2mL N,N-dimethylformamide (DMF) ultrasonic treatment for 30 minutes to form a 1 mg / mL black carbon nanotube suspension;

[0096] (2) The glassy carbon electrode was polished into a mirror surface with 0.3μm and 0.05μm aluminum oxide suspensions, and then washed with 95% ethanol and double distilled water in order to obtain a bare glassy carbon electrode;

[0097] (3) After drying the above-mentioned bare glassy carbon electrode with nitrogen with a purity of 99.999%, 5μL of carbon nanotube suspension was drip-coated onto the surface of the bare glassy carbon electrode, and then dried under a...

Embodiment 3

[0101] Preparation of functionalized carbon nanotube modified electrode:

[0102] 1. Preparation of carbon nanotube modified electrode:

[0103] (1) Place the multi-walled carbon nanotubes in a mixed acid of concentrated sulfuric acid and concentrated nitric acid (volume ratio 3:1) for oxidation treatment to introduce oxygen-containing groups. Disperse the oxidized multi-walled carbon nanotubes in 2mL N,N-dimethylformamide (DMF) ultrasonic treatment for 30 minutes to form a 1 mg / mL black carbon nanotube suspension;

[0104] (2) The glassy carbon electrode was polished into a mirror surface with 0.3μm and 0.05μm aluminum oxide suspensions, and then washed with 95% ethanol and double distilled water in order to obtain a bare glassy carbon electrode;

[0105] (3) After drying the above-mentioned bare glassy carbon electrode with nitrogen with a purity of 99.999%, 5μL of carbon nanotube suspension was drip-coated onto the surface of the bare glassy carbon electrode, and then dried under a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com