Method for determining content of phthalate in paper material for cigarette

The technology of a phthalate ester and a determination method is applied in the field of physical and chemical inspection of additives in cigarette paper materials, can solve problems such as low extraction efficiency, and achieve the effects of improving extraction effect, improving extraction efficiency and improving extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

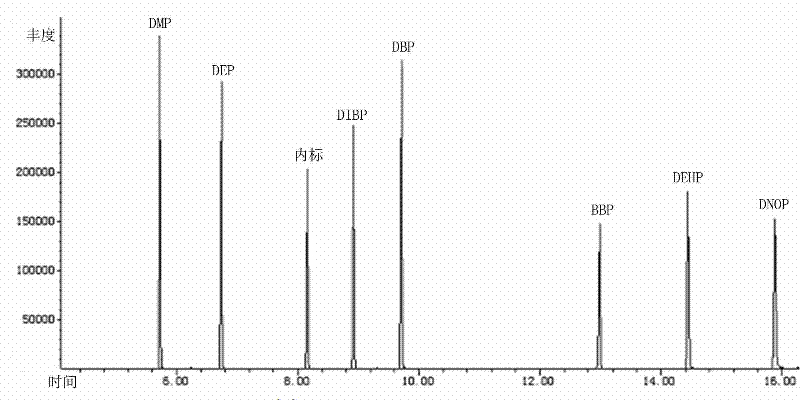

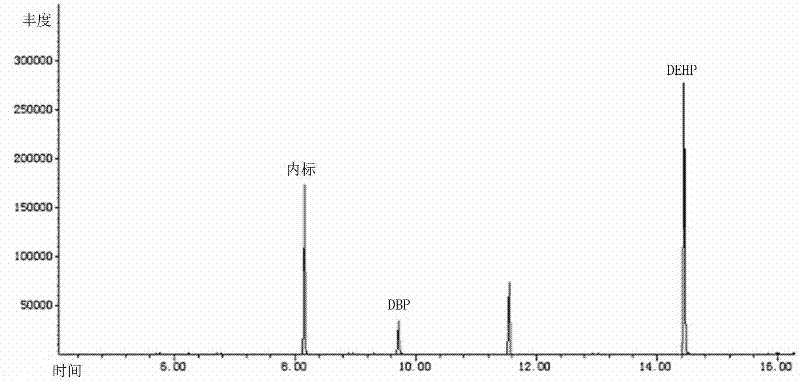

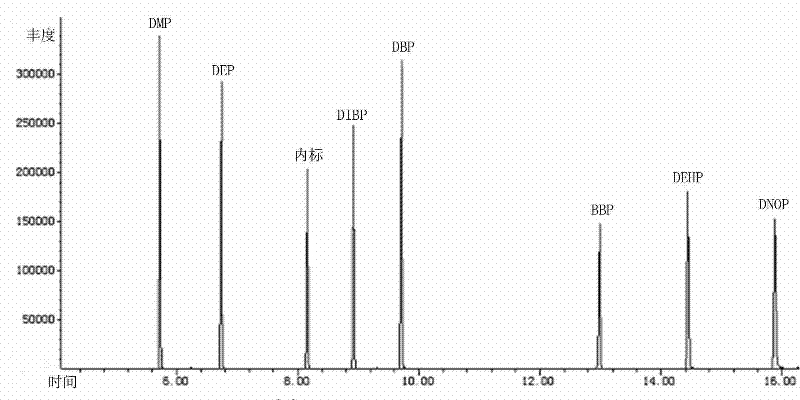

Image

Examples

Embodiment 1

[0034] The method for determining the content of phthalates in a cigarette tipping paper adopts the internal standard method and includes the following steps:

[0035] (1) Preparation of internal standard solution

[0036] Take internal standard benzyl benzoate, be mixed with benzyl benzoate isopropanol solution, the concentration of benzyl benzoate in benzyl benzoate isopropanol solution is 20mg / mL, this benzyl benzoate isopropanol solution is the internal standard solution;

[0037] (2) Preparation of sample solution

[0038] According to the provisions of YC 171-2008, cut a tipping paper for cigarettes, that is, accurately cut a sample of tipping paper for cigarettes with a length of 200mm and a width of 40mm (should include a single side), and the mass is about 0.3g. The good cigarette tipping paper is weighed on a balance, and then the cut cigarette tipping paper is cut into pieces not larger than 0.5cm×0.5cm, and the pieces are placed in a 50mL Erlenmeyer flask with a ...

Embodiment 2

[0052] The method for determining the content of phthalates in the wrapping paper of soft-pack cigarettes adopts the internal standard method and includes the following steps:

[0053] (1) Preparation of internal standard solution

[0054] Take internal standard benzyl benzoate, be mixed with the benzyl benzoate isopropanol solution that concentration is 20mg / mL;

[0055] (2) Preparation of sample solution

[0056] According to the regulations of YC / T 207-2006, cut a piece of cigarette soft box wrapping paper of a certain brand, and the cutting area is 15.5cm×10.0cm, put the cut cigarette soft box wrapping paper on a balance and weigh it, and then Cut into pieces not larger than 0.5cm×0.5cm, put the pieces in a 50ml corked Erlenmeyer flask, add 20mL water accurately into the 50ml corked Erlenmeyer flask, soak for 30 minutes, and then pour it into the 50ml corked Erlenmeyer flask Accurately add 20mL of isopropanol and 50μL of internal standard solution, then ultrasonically ex...

Embodiment 3

[0062] The method for determining the content of phthalates in inner lining paper for cigarettes adopts the internal standard method and includes the following steps:

[0063] (1) Preparation of internal standard solution

[0064] Take internal standard benzyl benzoate, be mixed with the benzyl benzoate isopropanol solution that concentration is 20mg / mL;

[0065] (2) Preparation of sample solution

[0066] According to the regulations of YC 264-2008, cut the inner lining paper of a certain brand of cigarettes, and the cutting area is 167cm 2 , put the cut cigarette soft box wrapping paper on a balance and weigh it, then cut it into pieces not larger than 0.5cm×0.5cm, put the pieces in a 50mL conical flask with a stopper, and pour it into the 50ml conical flask with a stopper Accurately add 20mL of water, soak for 30 minutes, then accurately add 20mL isopropanol and 50μL internal standard solution to the 50ml Erlenmeyer flask with stopper, then ultrasonically extract for 30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Column length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com