Peristaltic pump type weighing titrator and titration method thereof

A peristaltic pump and titrator technology, which is applied to the peristaltic pump weighing titrator and its titration field, can solve the problems of the complex structure of the plunger type automatic burette, the poor titration precision of the metering pump, and the inability to break through the titration precision. Achieve the effect of improving titration accuracy, low cost and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

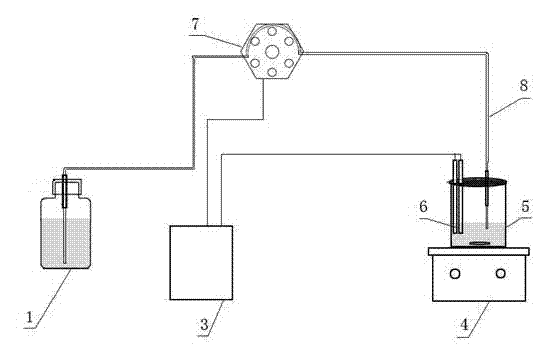

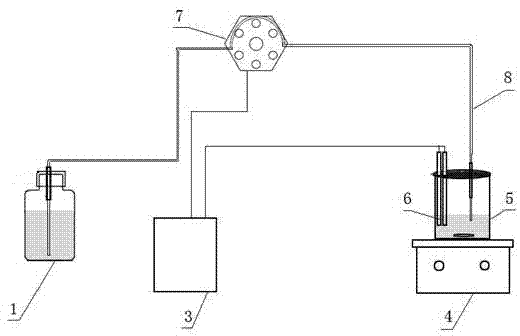

[0021] As shown in the figure, the peristaltic pump type weighing titrator of the present invention includes a titration unit, a measurement and control unit and a weighing bottle, and the titration unit includes a titration tank 5, a peristaltic pump 7 and a capillary 8, and the inlet and outlet of the peristaltic pump 7 are respectively Pass into weighing bottle 1 and titration cell 5 by capillary 8; Electrode 6 is installed in the titration cell 5, and the electric signal input end of measurement and control unit 3 is connected with electrode 6 in the titration cell, so that can measure titration cell 5 The electrode potential change of the medium solution during the titration process can be used to determine whether the end point of the reaction is approached or reached. The control output terminal of the measurement and control unit 3 is connected to the peristaltic pump 7, and can control the peristaltic pump to high speed, low speed, step rotation or stop rotation accord...

Embodiment 2

[0031] The peristaltic pump 7 of the peristaltic pump type weighing titrator of the present invention can also be provided with a speed regulating knob (not shown in the figure), so that when performing titration analysis, proceed according to the following steps:

[0032] (1) Pour the titration solution into the weighing bottle first, immerse a capillary connected to the peristaltic pump into the weighing bottle containing the titration solution, and put the other capillary into the waste liquid bottle;

[0033] (2) Run the peristaltic pump to rinse the titration solution and fill the plastic capillary and peristaltic pump hose;

[0034] (3) Pull out the plastic capillary and weigh the weighing bottle with an electronic balance;

[0035] (4) Pour the solution of the substance to be tested into the titration tank, and insert the two capillaries into the weighing bottle and the titration tank for titration;

[0036] (5) Drop the indicator that can display the titration process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com