Optical fiber composite insulator for measuring temperature of high-voltage busbar and preparation method

A fiber optic composite and insulator technology, applied in thermometers, insulators, measuring devices, etc., can solve the problems of reduced air clearance and insulation grade degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

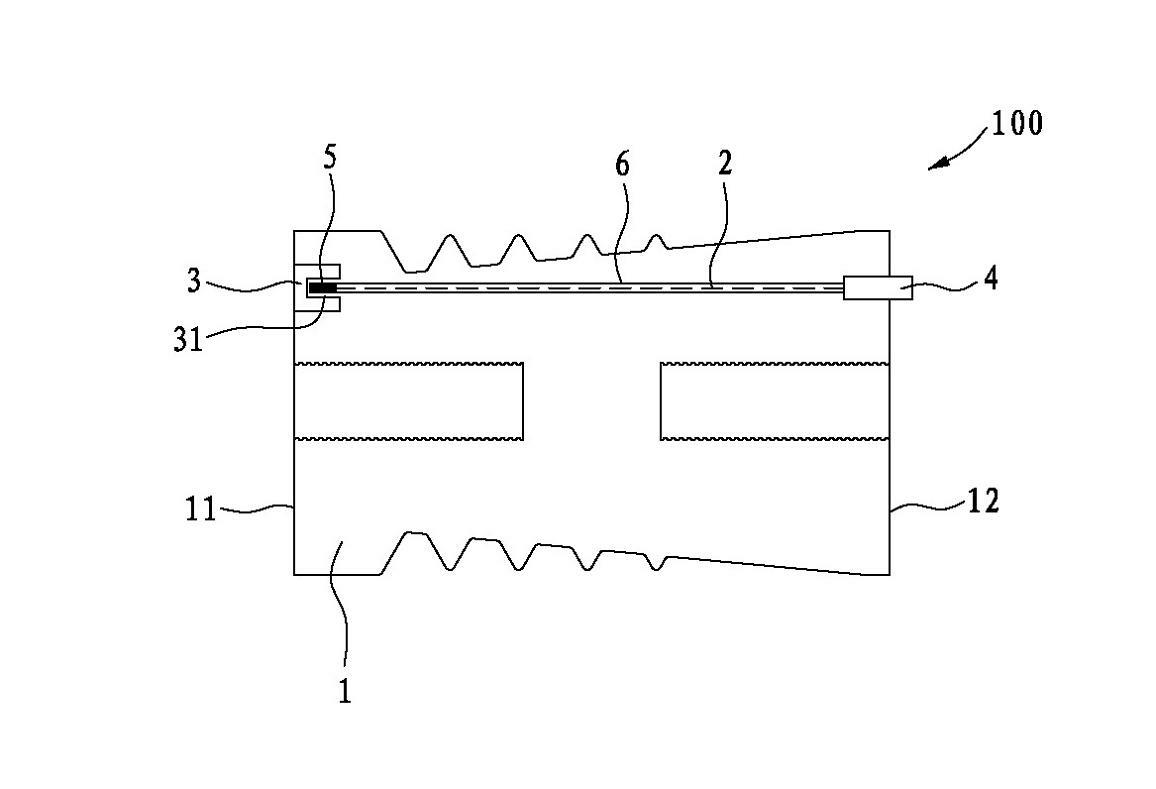

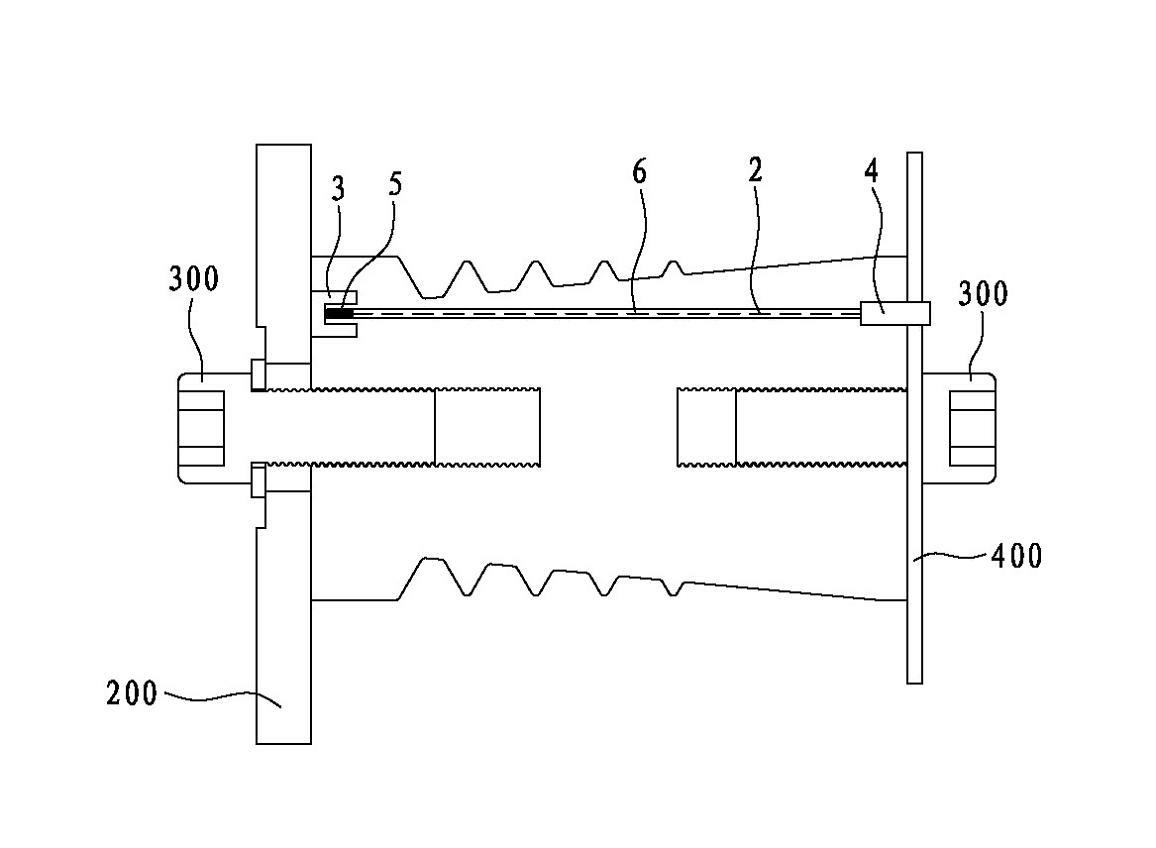

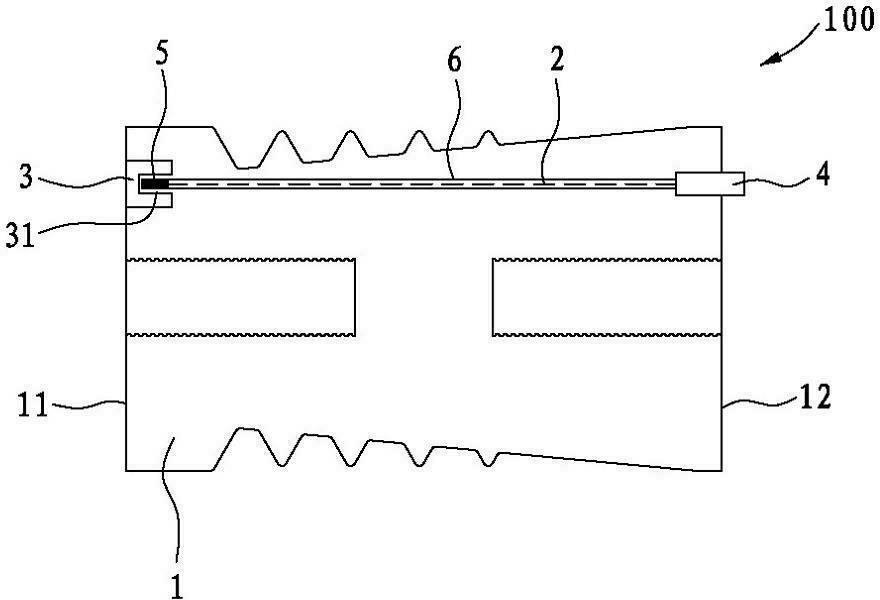

[0035] Such as figure 1 with figure 2 As shown, it is a preferred embodiment of the present invention related to an optical fiber composite insulator 100 for measuring the temperature of a high-voltage busbar 200. The optical fiber composite insulator 100 includes an insulator body 1 having a first assembly surface 11 and a second Two assembly surfaces 12, the first assembly surface 11 is fixedly connected with the high-voltage busbar 200, specifically, it can be directly fixed by locking screws 300; the second assembly surface 12 can be connected with the switchgear housing 400, which is also They can be directly connected by means of locking screws 300 .

[0036] The improvement of the present invention is that: the optical fiber composite insulator 100 also includes: an optical fiber 2, a heat conducting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com