Machining method for antenna housing

A processing method and radome technology, applied in the field of material processing, can solve the problems of inability to meet the application requirements of deep monitoring of high temperature and high pressure, complex production process, unstable quality, etc., and achieve reliable quality, high production efficiency, and quality structure. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

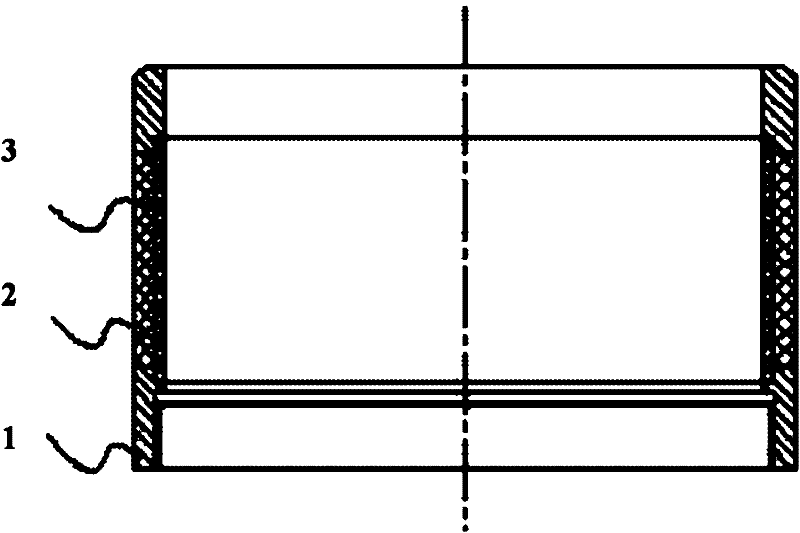

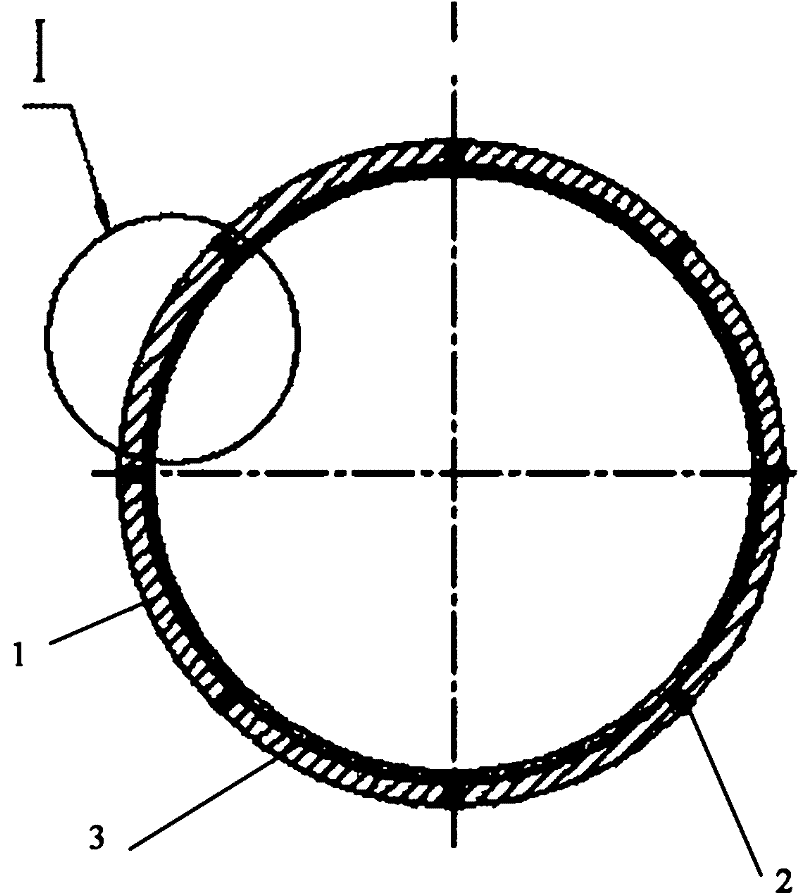

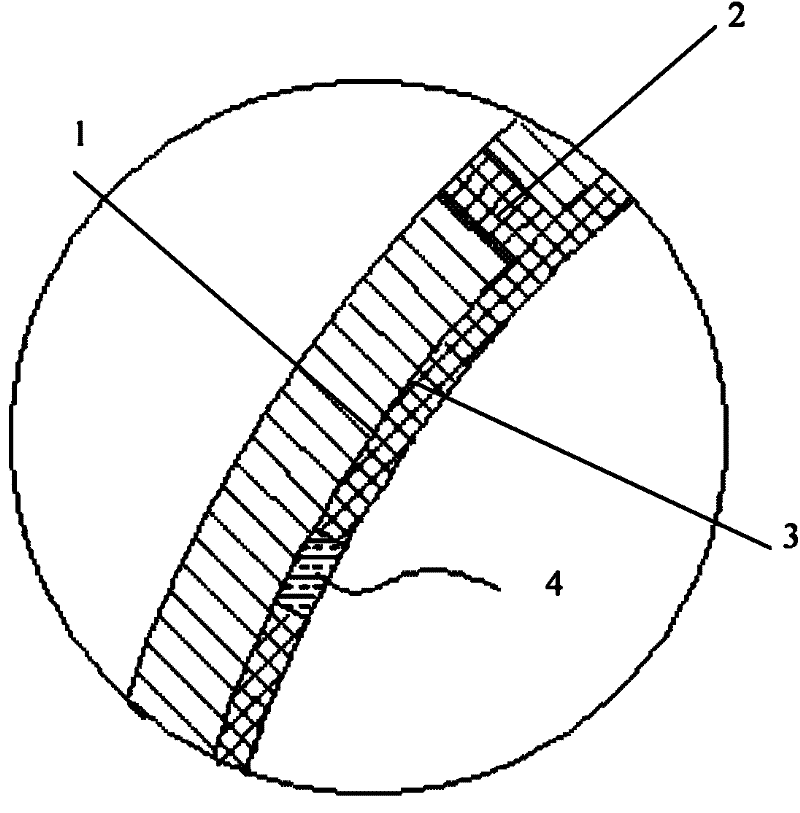

[0018] see Figure 1-Figure 3 , the processing method of radome of the present invention, comprises the following steps: comprises the following steps:

[0019] 1) Drill the material of the cylinder block 1, turn the inner diameter and outer diameter of the cylinder block 1, wire cut the side groove, mill the filling strip 2 and the squeeze strip 4, turn the material of the filling ring 3 and fill it in the filling ring 3 The through groove is milled on the top; the width of the squeeze strip 4 is interference fit with the width of the through groove on the filling ring 3;

[0020] 2) Perform sand blasting on the inner diameter of the cylinder body 1, the side channel on the cylinder body 1 and the outer diameter of the filling ring 3, and polish the filling strip 3 and the squeeze strip 4, and clean them after sand blasting;

[0021] 3) Spray primer on the inner diameter of the cylinder body 1, the side channel on the cylinder body 1 and the outer diameter of the filling rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com