Optical communication module

An optical communication module and optical signal technology, which is applied in the direction of optics, light guides, lasers, etc., can solve the problems of reduced connection terminal strength, difficulty in thinning, and reduced optical communication accuracy, achieving improved strength, high reliability, and high communication accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

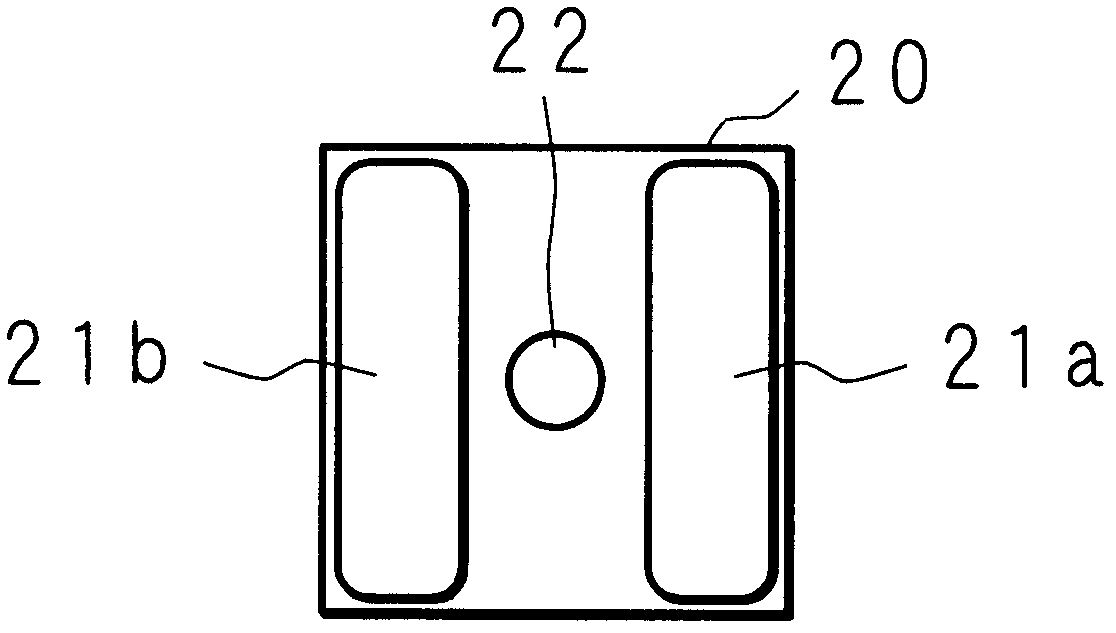

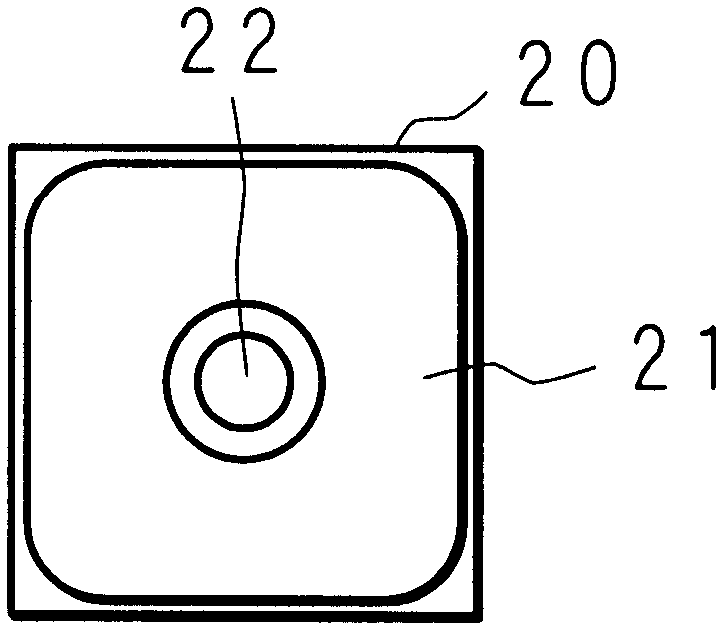

[0125] Figure 9A and Figure 9B It is a schematic diagram showing the structure of the light transmission table 70a included in the optical communication module according to Modification 1 of the present invention, Figure 9A Indicates the structure above the light-passing table 70a, Figure 9B It shows the structure of the lower surface of the light transmission table 70a. the above Figure 3A and Figure 3B The illustrated light-transmitting table 70 is formed of a translucent synthetic resin, and the main body of the light-transmitting table 70 forms a light-transmitting portion through which light passes, but it is not limited thereto. The light transmission stand 70 a of Modification 1 is formed of a synthetic resin that does not transmit light, and has a substantially circular light transmission hole 71 that allows light to pass through the substantially center in a planar view. Thus, the laser diode 20 connected to the conductive plate 60 provided on the upper sur...

Deformed example 2

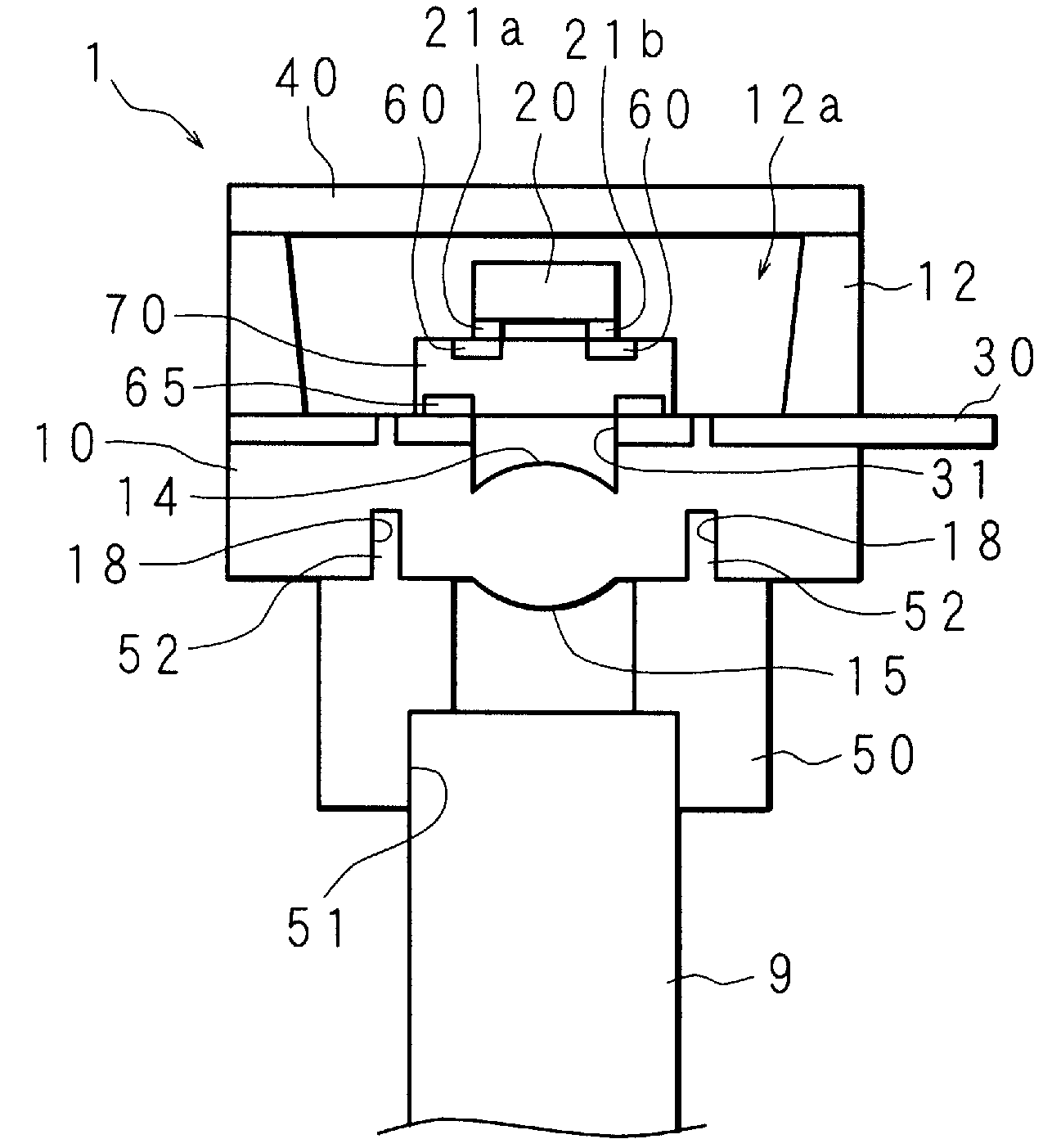

[0128] Figure 10 A schematic cross-sectional view showing the structure of an optical communication module according to Modification 2 of the present invention. The light transmitting table 70b of the OSA1 according to Modification 2 has a substantially square plate shape larger than the laser diode 20 in plan view, and is made of metal. Therefore, the light-transmitting table 70b has no light-transmitting property, and a substantially circular light-transmitting hole 71 is formed at the substantially center in a planar view.

[0129] That is, the light-passing table 70b of Modification 2 is to Figure 9A and Figure 9B The form in which the light transmission table 70a and the conductive plates 60 and 65 of the above-mentioned Modification 1 are integrated is shown. In other words, the light-transmitting table 70b of Modification 2 has the functions of the conductive plates 60 and 65 on the light-transmitting table 70a by making the light-transmitting table 70a of Modific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com