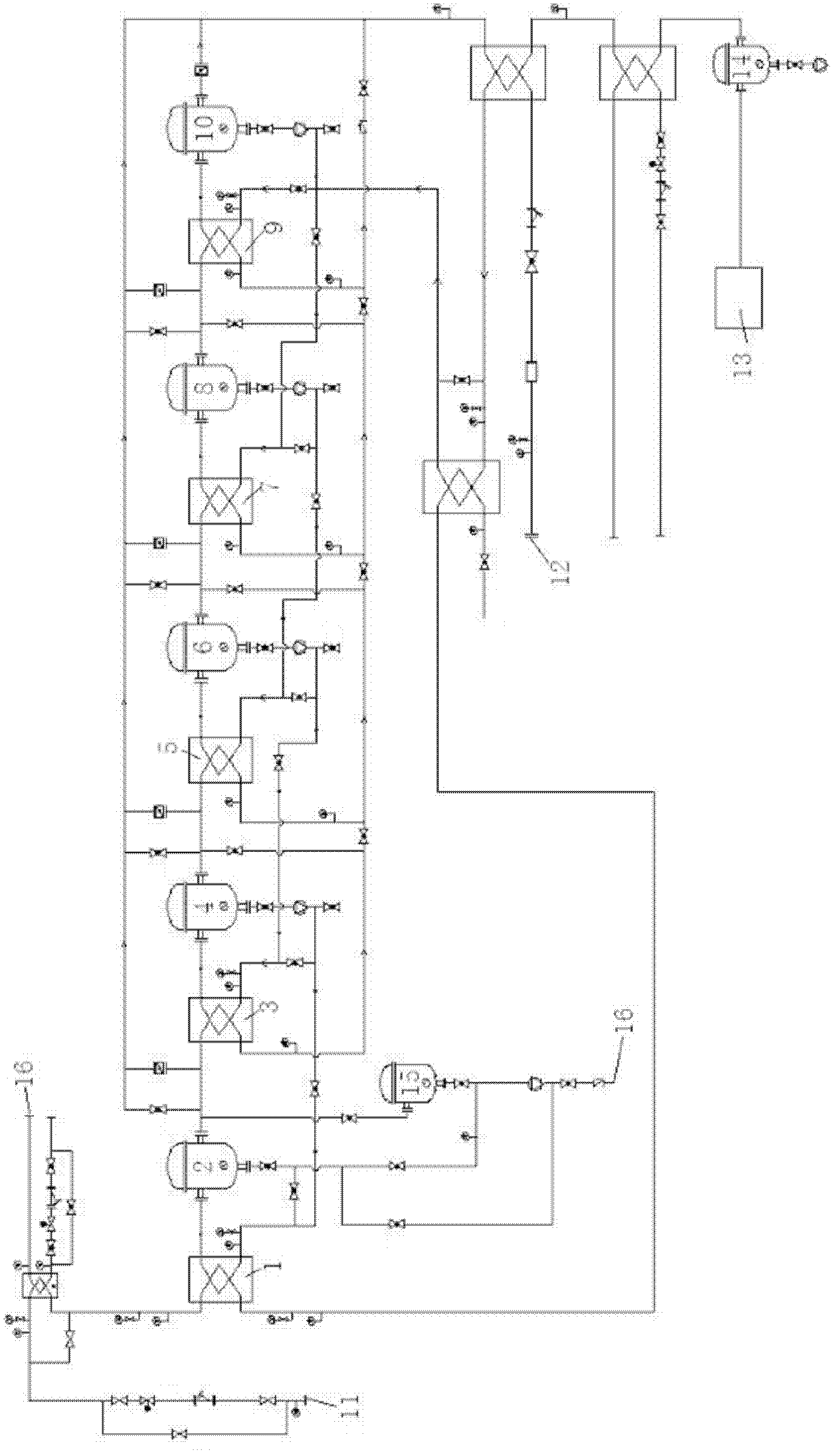

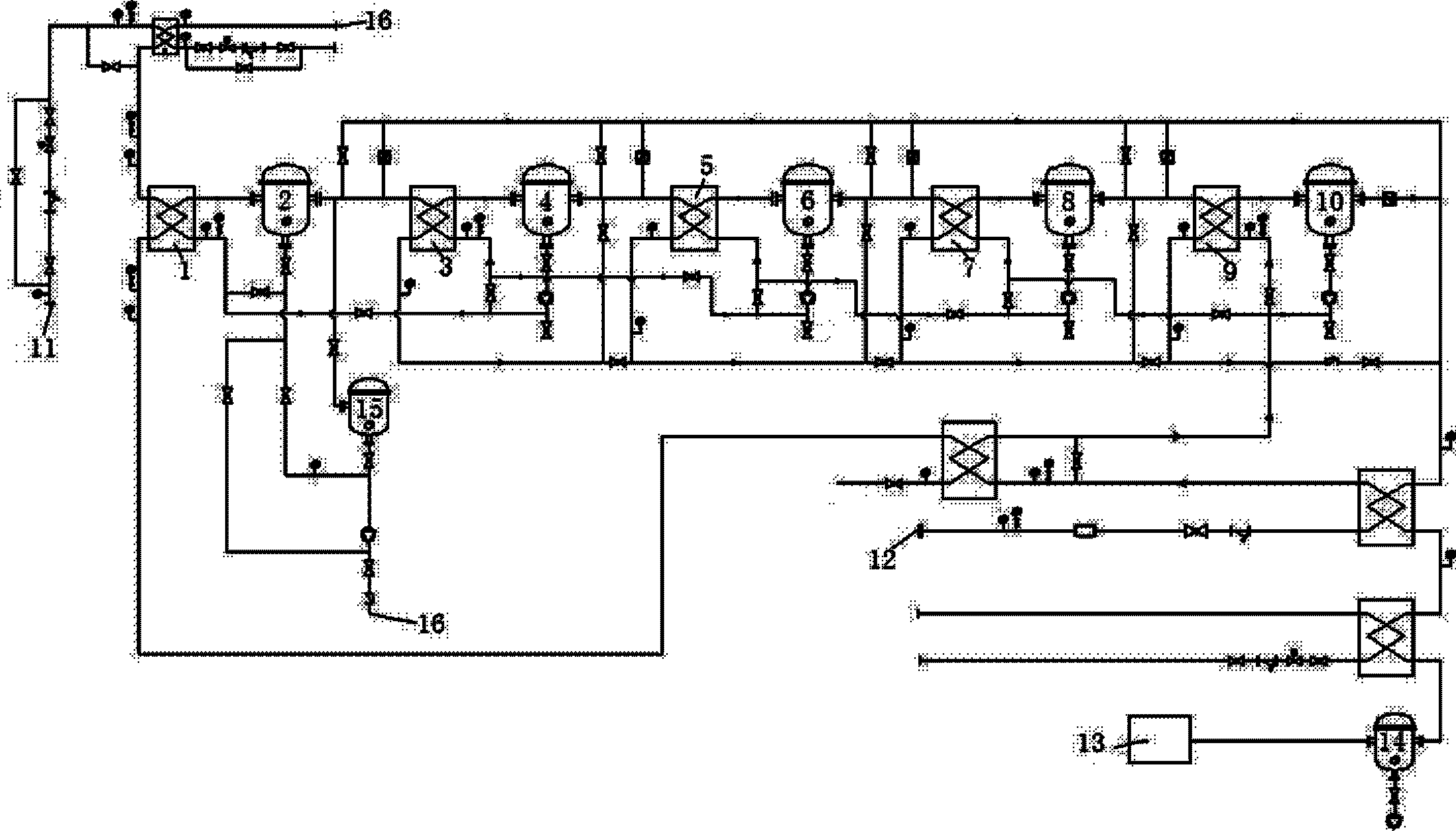

Multi-effect plate type rising film countercurrent evaporation concentration device and method thereof

An evaporation concentration and evaporation device technology, which is applied in the field of multi-effect plate type rising film countercurrent evaporation concentration device, can solve the problems of easy crystallization and precipitation of heat-sensitive substances, and achieve the effect of avoiding the possibility of surface scaling and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Concentration of sodium gluconate stock solution: when the mother liquor generated by the oxidation method enters the fifth effect of the unit, the temperature is 45 degrees Celsius, the Baume degree is 16, the absolute vacuum pressure of the fifth effect unit is 0.0123MPa, and the evaporation temperature is 50 degrees Celsius; after evaporation and dehydration, it enters the fourth effect The temperature of the mother liquor in the evaporation unit is 50 degrees Celsius, the Baume degree is increased to about 18-19, the vacuum absolute pressure of the fourth effect unit is 0.018 MPa, and the evaporation temperature is 57 degrees Celsius; after evaporation and dehydration, the temperature of the mother liquor is 57 degrees Celsius when entering the third effect evaporation unit , the Baume degree is increased to about 21, the absolute vacuum pressure of the third effect unit is 0.024MPa, and the evaporation temperature is 64 degrees Celsius; after evaporation and dehydrat...

Embodiment 2

[0037]Concentration of gluconolactone stock solution: when the mother liquor produced by the fermentation method enters the unit, the original concentration is about 17%, and the temperature is about 30-35 degrees Celsius. After being heated by a series-connected plate condenser and condensate heat exchanger, the temperature rises to about 40 degrees Celsius. Entering the fifth effect, the absolute vacuum pressure of the fifth effect unit is controlled at 0.01MPa, and the evaporation temperature is 46 degrees Celsius. The temperature is 53 degrees Celsius; after evaporation and dehydration, the mother liquor temperature is 53 degrees Celsius when entering the third effect evaporation unit, the absolute vacuum pressure of the third effect unit is 0.02MPa, and the evaporation temperature is 60 degrees Celsius; after evaporation and dehydration, the mother liquor temperature when entering the second effect evaporation unit is 60 degrees Celsius, the absolute vacuum pressure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com