Shale oil solid-liquid separator

A solid-liquid separator, shale oil technology, applied in filtration separation, separation method, fixed filter element filter, etc., can solve the problems of low filtration separation efficiency, many rotating parts, complicated maintenance process, etc., to improve filtration efficiency and effect, reduce manual participation, and improve the effect of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

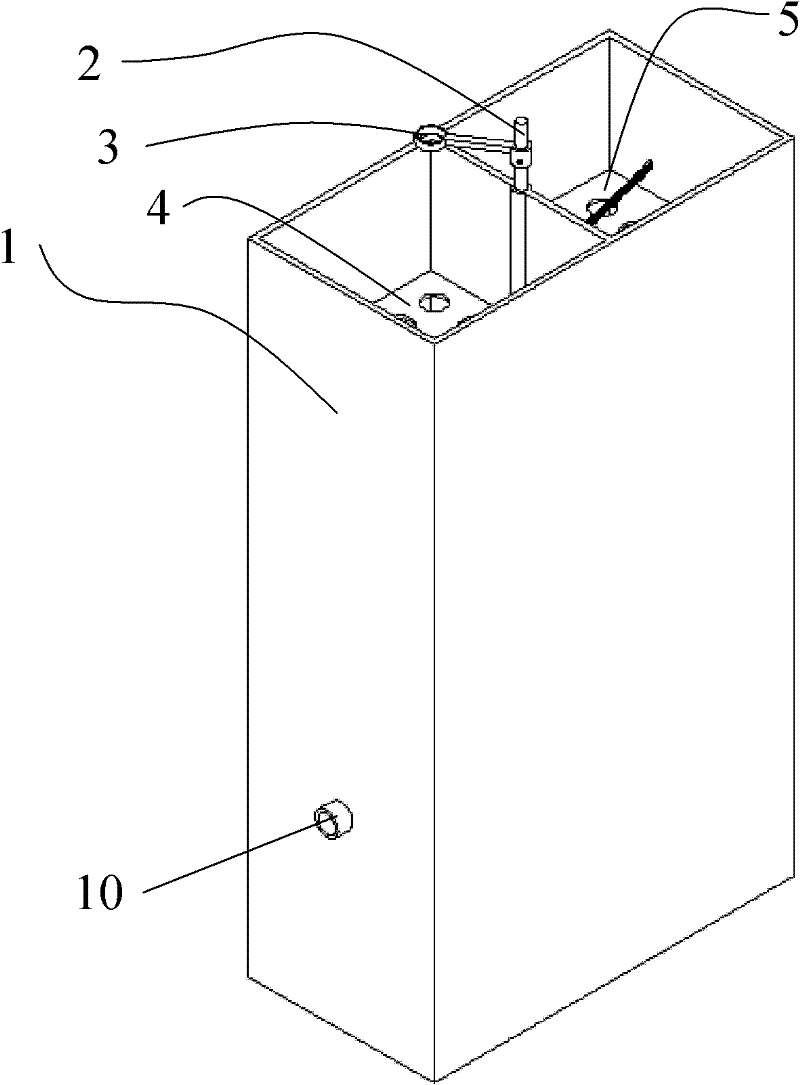

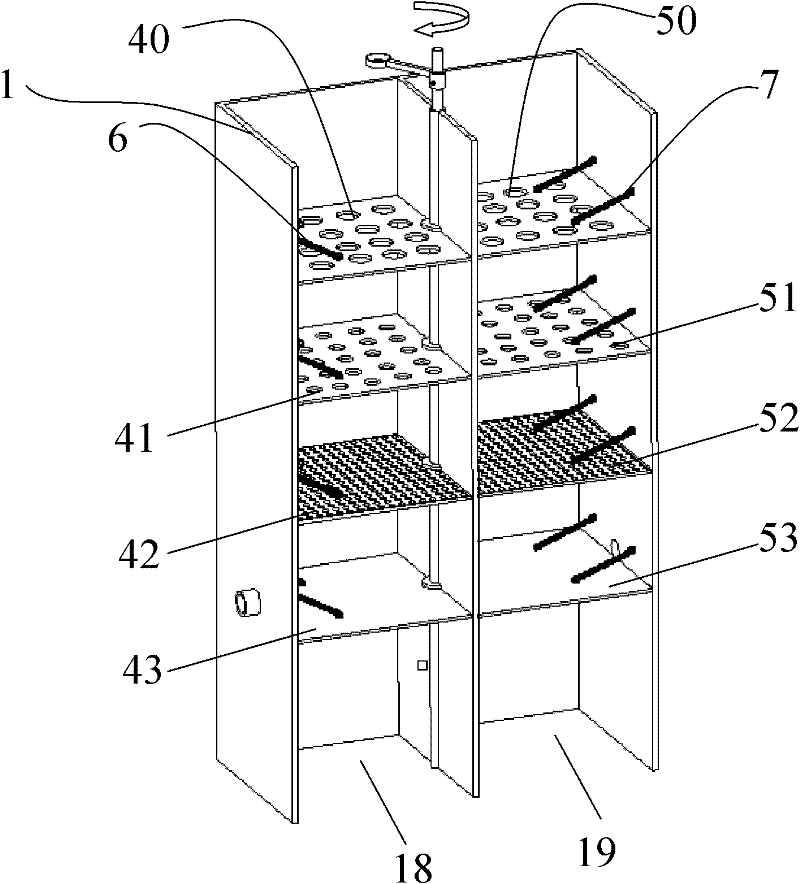

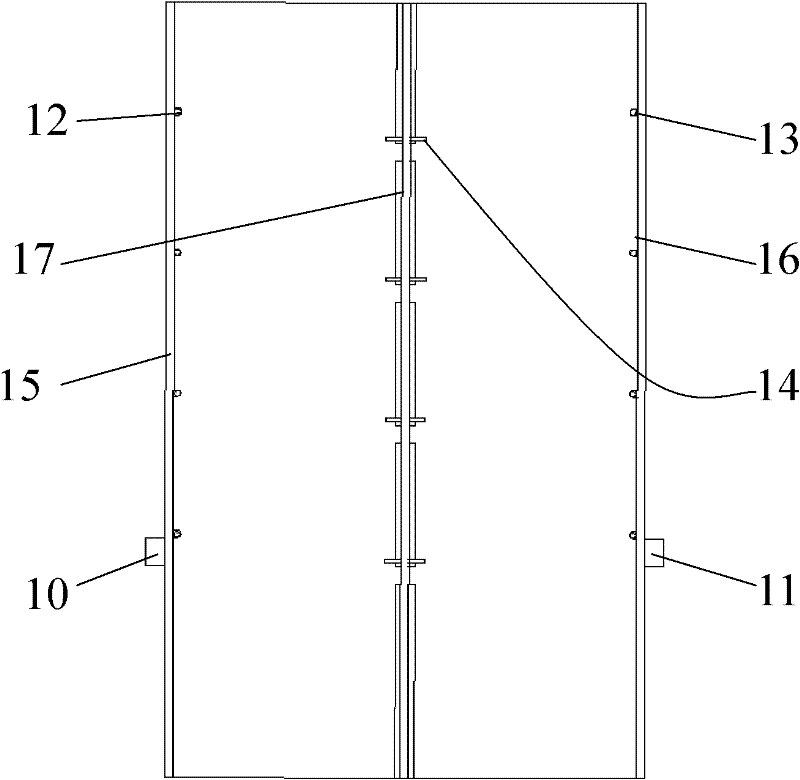

[0044] figure 1 is the overall schematic diagram of the shale oil solid-liquid separator, figure 2It is the internal structure diagram of the shale oil solid-liquid separator, as shown in the figure, the shale oil solid-liquid separator mainly includes the box body 1, the intermittent rotating shaft 2, the oil inlet pipe support 3, the left plate module 4, and the right plate module 5. Left spring module 6, right spring module 7, plate support module 8.

[0045] The left plate module 4 includes a left large particle separation plate 40, a left middle particle separation plate 41, a left small particle separation plate 42, and a left oil baffle plate 43; the right plate module 5 includes a right large particle separation plate 50, a right middle particle separation plate 51 , the right small particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com