Small-sized glass double-sided cleaning machine

A washing machine, small-sized technology, applied in the direction of cleaning flexible objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems that cannot be cleaned on both sides at the same time, achieve small footprint, high efficiency, high cleaning degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

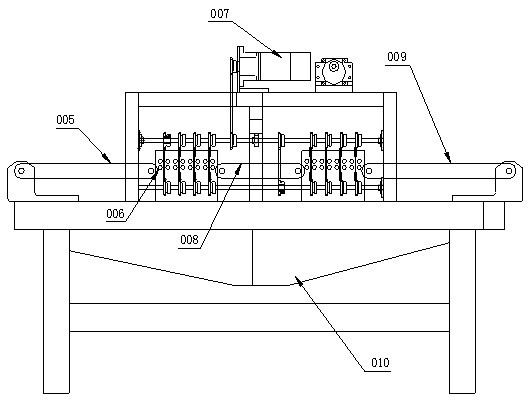

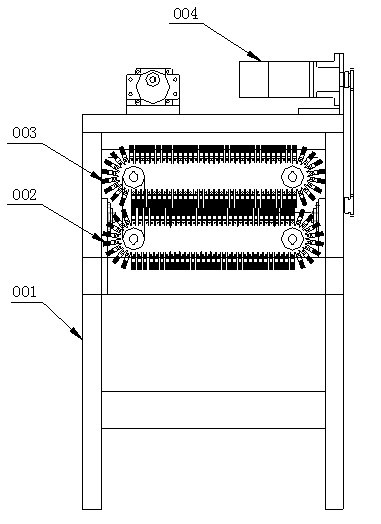

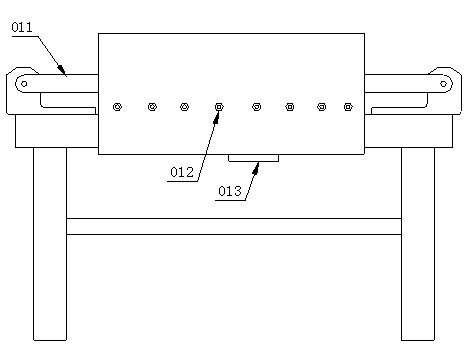

[0015] The cleaning structure of the embodiment of the present invention is shown in the accompanying drawings, and mainly includes a frame 001, a conveying mechanism, a roller 006, a cleaning device and a drying device. Its main feature is that the roller 006 is wrapped in pairs with elastic Silicone rubber rollers, there is a gap between each group of rollers, the sprocket circulation brush 002 and 003 of the cleaning device are placed in the gap between the rollers, the sprocket circulation brush 002 and 003 are connected to the speed regulating motor 007 .

[0016] In the embodiment of the present invention, there are upper and lower pairs of sprocket type circulating brushes 003, 002 in the gap between the rollers 006 of the double-sided cleaning machine.

[0017] Frame 001 is the support structure of washing machine, bears the whole weight of equipment and guarantees the rigidity of equipment.

[0018] The conveying mechanism includes several speed-adjustable drive moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com