Manufacture method for inner-threaded steel pipe applied to supercritical or ultra supercritical fossil power unit

A technology of ultra-supercritical and thermal power units, applied in the field of internal thread pipe manufacturing, can solve the problems of less than 100,000 k, exhaust gas emissions, resource waste, etc., and achieve the effects of prolonging service life, preventing burnout, and enhancing mixing and turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

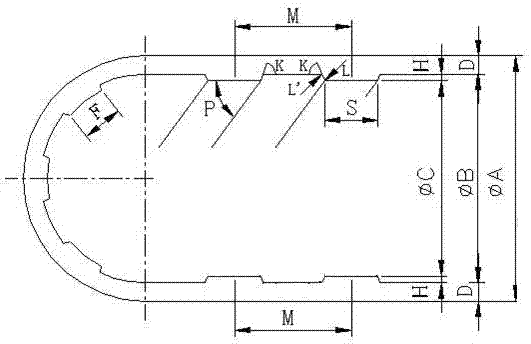

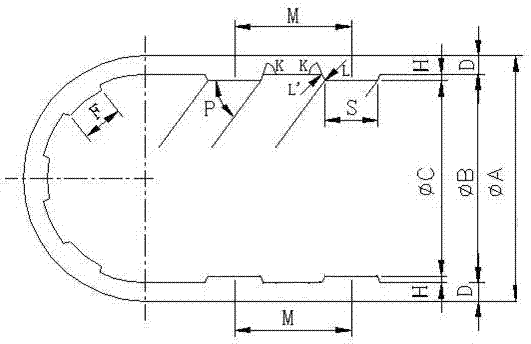

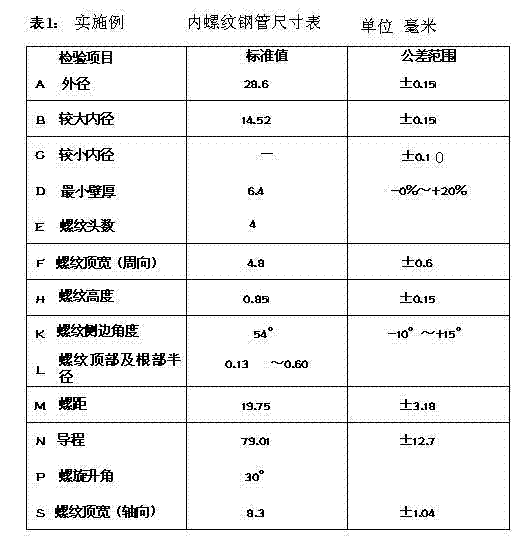

[0013] Such as figure 1 As shown, a method for manufacturing internally threaded steel pipes suitable for supercritical and ultra-supercritical thermal power units, the method is carried out according to the following process: manufacturing tube blanks - straightening - flat head and tail - flaw detection - tail head - annealing - pickling - Phosphating-lubrication-cold drawing-finished product heat treatment-straightening-head and tail cutting-non-destructive testing-surface inspection-packing-warehousing.

[0014] Wherein, the manufacturing of the tube blank includes: cutting the round steel billet according to the selected material, putting the round steel billet into an inclined-bottom furnace for heating, and piercing into a hollow steel billet through a piercing machine.

[0015] The straightening is: shaping the hollow steel slab so that it meets the requirement of non-straightness.

[0016] The flat head and tail are: the two ends of the hollow steel billet are machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com