Method for processing special wires for linear bearings

A linear bearing and special-shaped technology, which is applied in the field of metal materials, can solve the problems of inability to process special-shaped wires, such as comprehensive performance requirements, and achieve the effects of solving processing difficulties, making up for the lack of cold-rolled performance, and improving straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

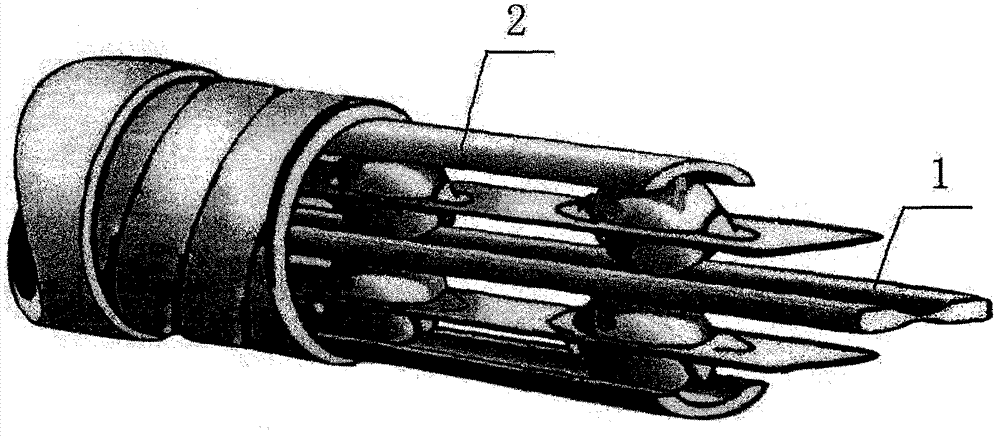

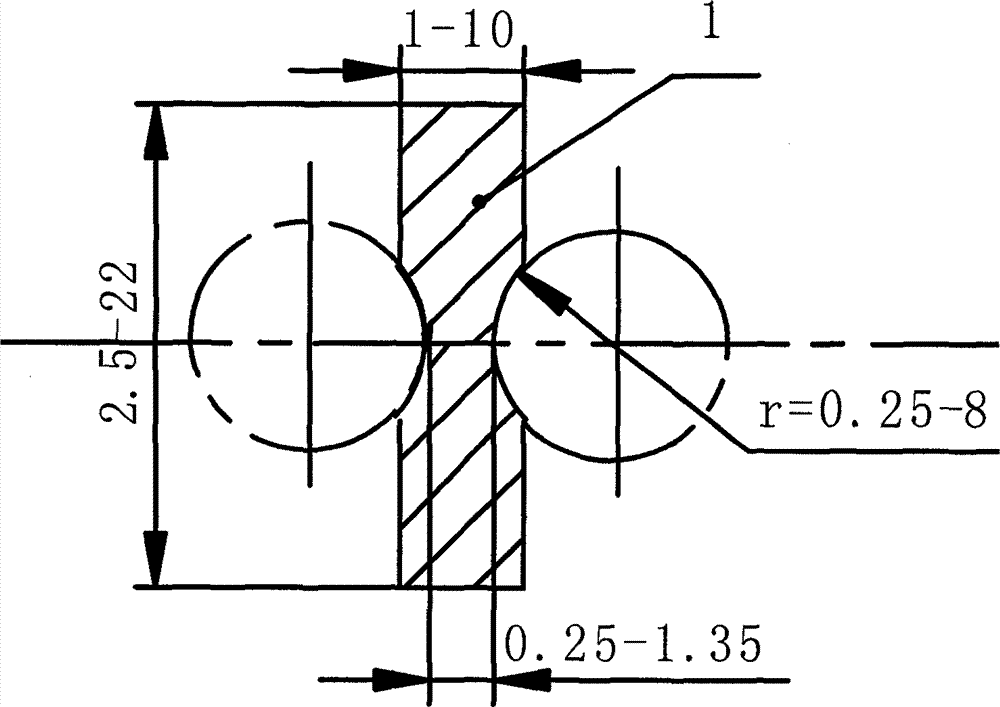

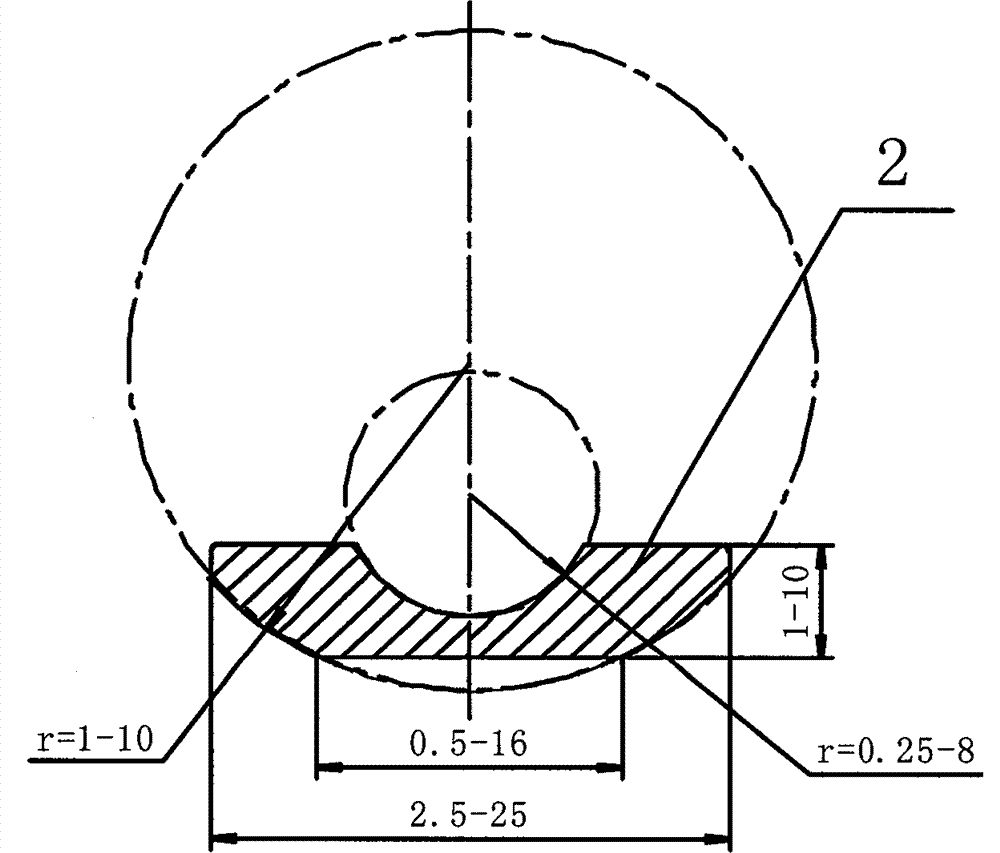

[0028] 1Cr18Ni9 is selected as the special-shaped wire raw material, according to the technological process of hot-rolled wire rod→solution treatment→cold-drawn round wire→solution treatment→cold-rolled flat wire→solution treatment→cold-rolled special-shaped wire→straightening→heat treatment→polishing, The process parameters of the produced special-shaped wire are controlled as follows:

[0029] (1) The selected 1Cr18Ni9 alloy is forged and hot-rolled by a conventional hot-working method, and the steel ingot is forged into a square billet of a certain specification by selecting a suitable forging temperature, and then hot-rolled into a wire rod of the required specification, and then solid solution treated. Use this as the blank for the next step of cold processing;

[0030] (2) Cold-drawn the hot-rolled wire rod. The specifications of the cold-drawn round wire are φ3.8mm (core slider 1) and φ4.3mm (fixed slider 2). Solution treatment is carried out after cold drawing, and the...

Embodiment 2

[0037] 1Cr17Ni7 is selected as the alloy material, according to the process flow of hot-rolled wire rod→solution treatment→cold-drawn round wire→solution treatment→cold-rolled flat wire→solution treatment→cold-rolled special-shaped wire→straightening→heat treatment→polishing process, production The special-shaped wire process parameters are controlled as follows:

[0038] (1) The selected 1Cr17Ni7 alloy is forged and hot-rolled by conventional hot-working methods, and the steel ingot is forged into a square billet of a certain specification by selecting a suitable forging temperature, and then hot-rolled into a wire rod of the required specification, and then solid solution treated. Use this as the blank for the next step of cold processing;

[0039](2) Cold-drawn the hot-rolled wire rod. The specifications of the cold-drawn round wire are φ6.0mm (core slider 1) and φ5.0mm (fixed slider 2). Solution treatment is carried out after cold drawing, and then rolled Make a flat wire...

Embodiment 3

[0046] 1Cr18Ni12 is selected as the alloy material, according to the technological process of hot-rolled wire rod→solution treatment→cold-drawn round wire→solution treatment→cold-rolled flat wire→solution treatment→cold-rolled special-shaped wire→straightening→heat treatment→polishing process, production The special-shaped wire process parameters are controlled as follows:

[0047] (1) The selected 1Cr18Ni12 alloy is forged and hot-rolled by a conventional hot-working method, and the steel ingot is forged into a square billet of a certain specification by selecting a suitable forging temperature, and hot-rolled into a wire rod of a required specification, and then subjected to solution treatment. Use this as the blank for the next step of cold processing;

[0048] (2) Cold-drawn the hot-rolled wire rod. The specifications of the cold-drawn round wire are φ6.5mm (core slider 1) and φ6.7mm (fixed slider 2). Solution treatment is carried out after cold drawing, and then rolled M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com