Integral mold casting method for resin sand of support piece of bulldozer

A technology of oblique supports and bulldozers, applied in casting molding equipment, molds, mold components, etc., can solve problems such as good mechanical properties, and achieve the effects of good mechanical properties, smooth surface, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

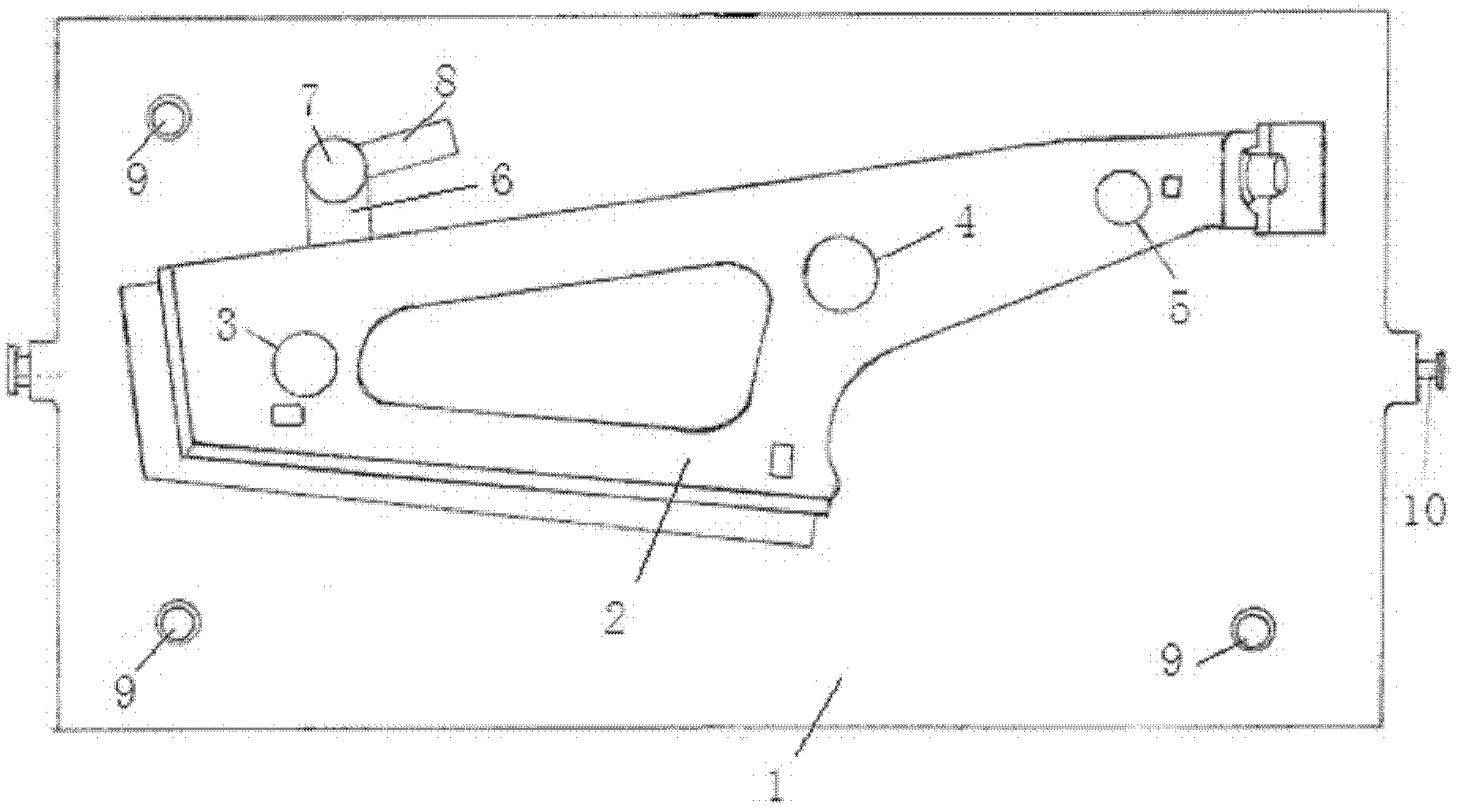

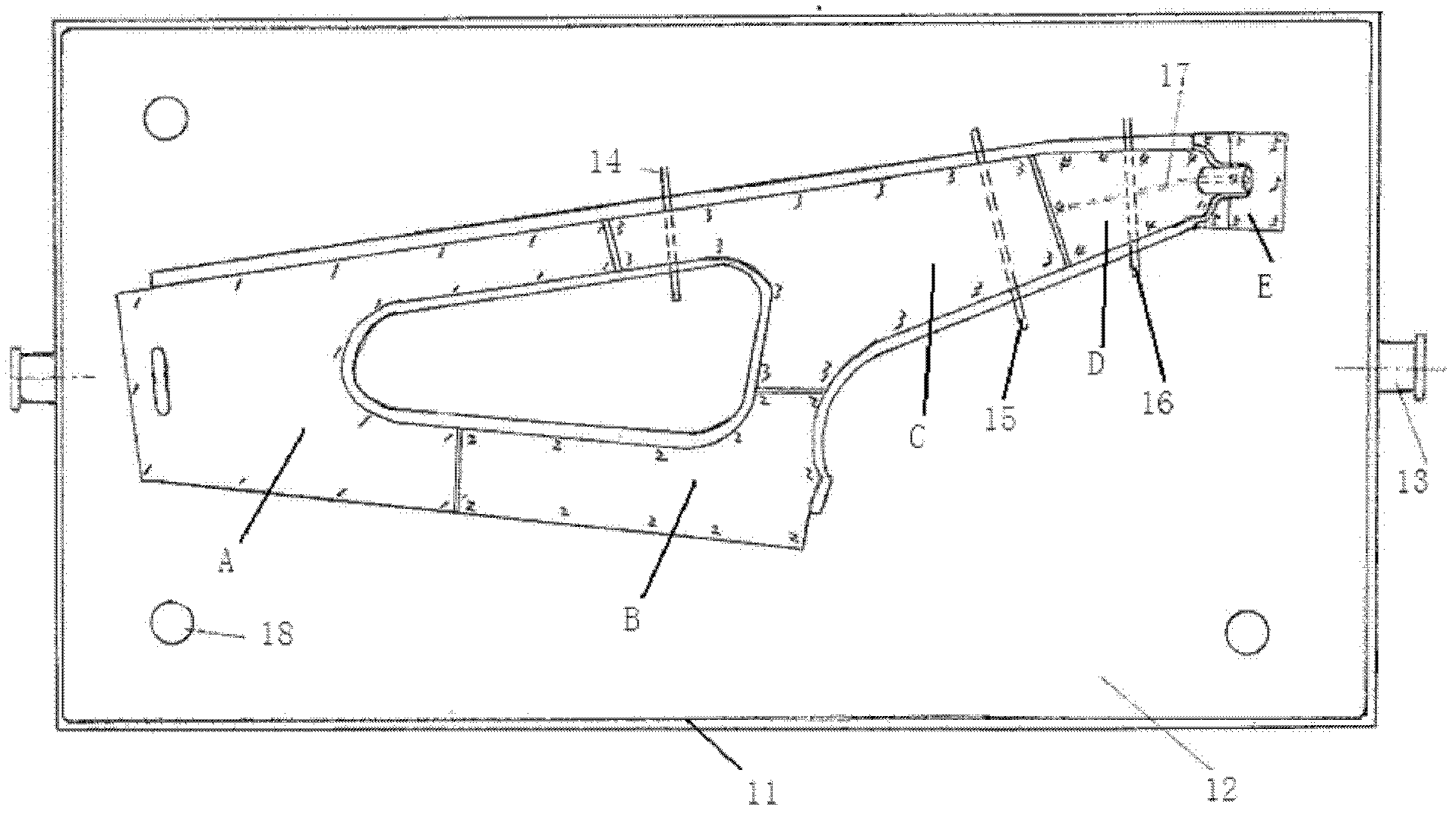

[0031] When utilizing the method of the present invention to cast bulldozer oblique supports, two integral molds (wherein, one pair of bulldozer left oblique supports and one pair of bulldozer right oblique supports), each pair of integral molds are divided into upper and lower templates. A resin sand integral mold casting method for bulldozer oblique supports according to the present invention:

[0032] Step 1 Make the overall mold:

[0033] According to the shape and size of the oblique support of the bulldozer to be manufactured, two overall models, the upper and lower, are made respectively. The same side of the two overall models has a corresponding sprue model, and the two overall models are respectively fixed on their respective receiving base plates. A plurality of positioning pins are arranged on the corresponding positions of the receiving base plates, thereby constituting the upper and lower templates corresponding to each other of the overall mold of the oblique su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com